17

3. Ensure that the clapper is free of contaminants, dirt, and

mineral deposits.

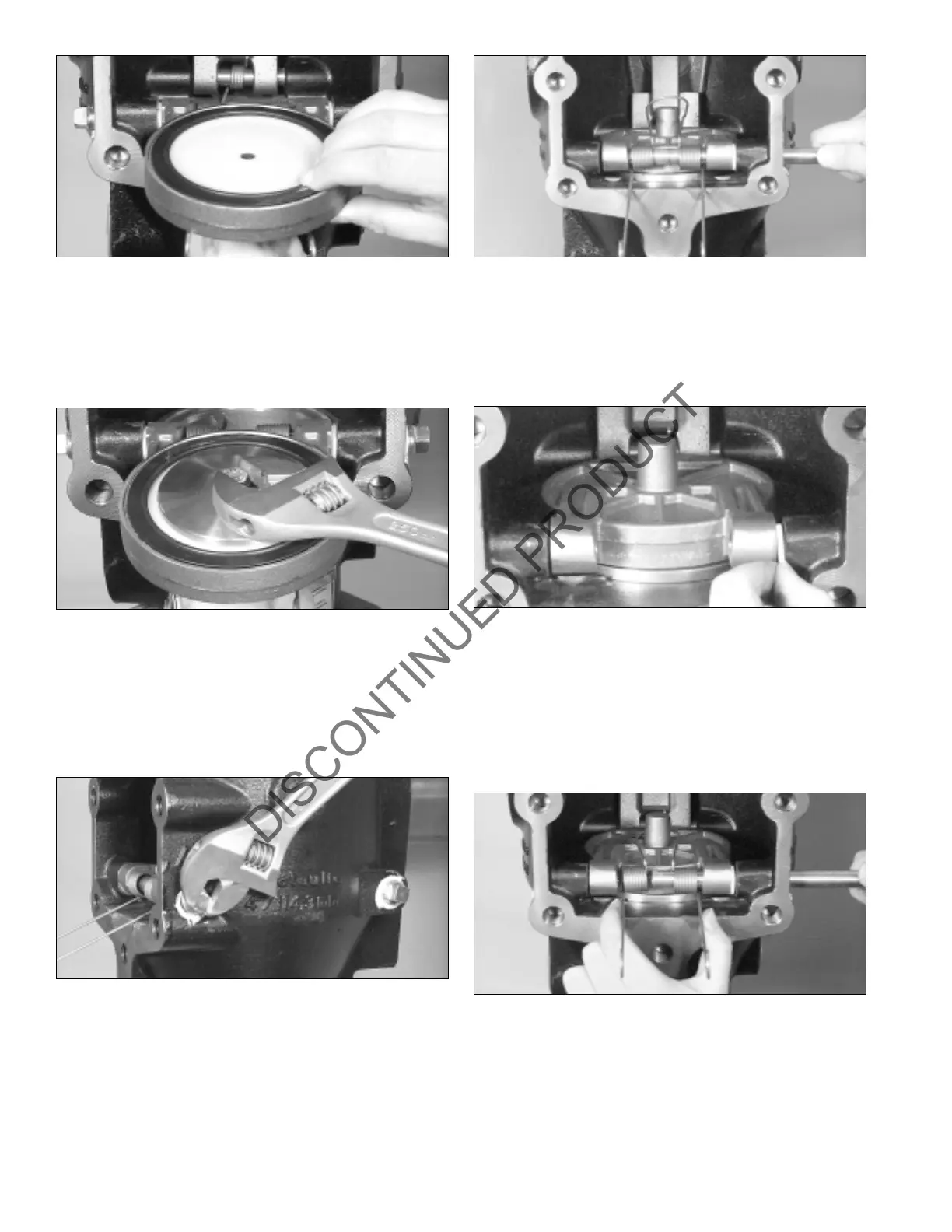

3a. Carefully put the rubber seal into the clapper so that

the clapper retains the outer edge of the seal. Make sure

that the seal is pushed all the way down in the clapper and

that the outer seal-retaining ring snaps into position.

4. Place the brass retaining ring onto the seal and bolt the

retaining ring to the clapper with the bolt/washer pro-

vided. Tighten the bolt/washer sufficiently, and apply an

additional ¹⁄₂ turn to ensure a proper seal.

REMOVING THE

CLAPPER ASSEMBLY

1. Remove the shaft retaining plugs from the valve body.

2. Slide the clapper’s shaft through the body and the clap-

per.

3. Remove the clapper.

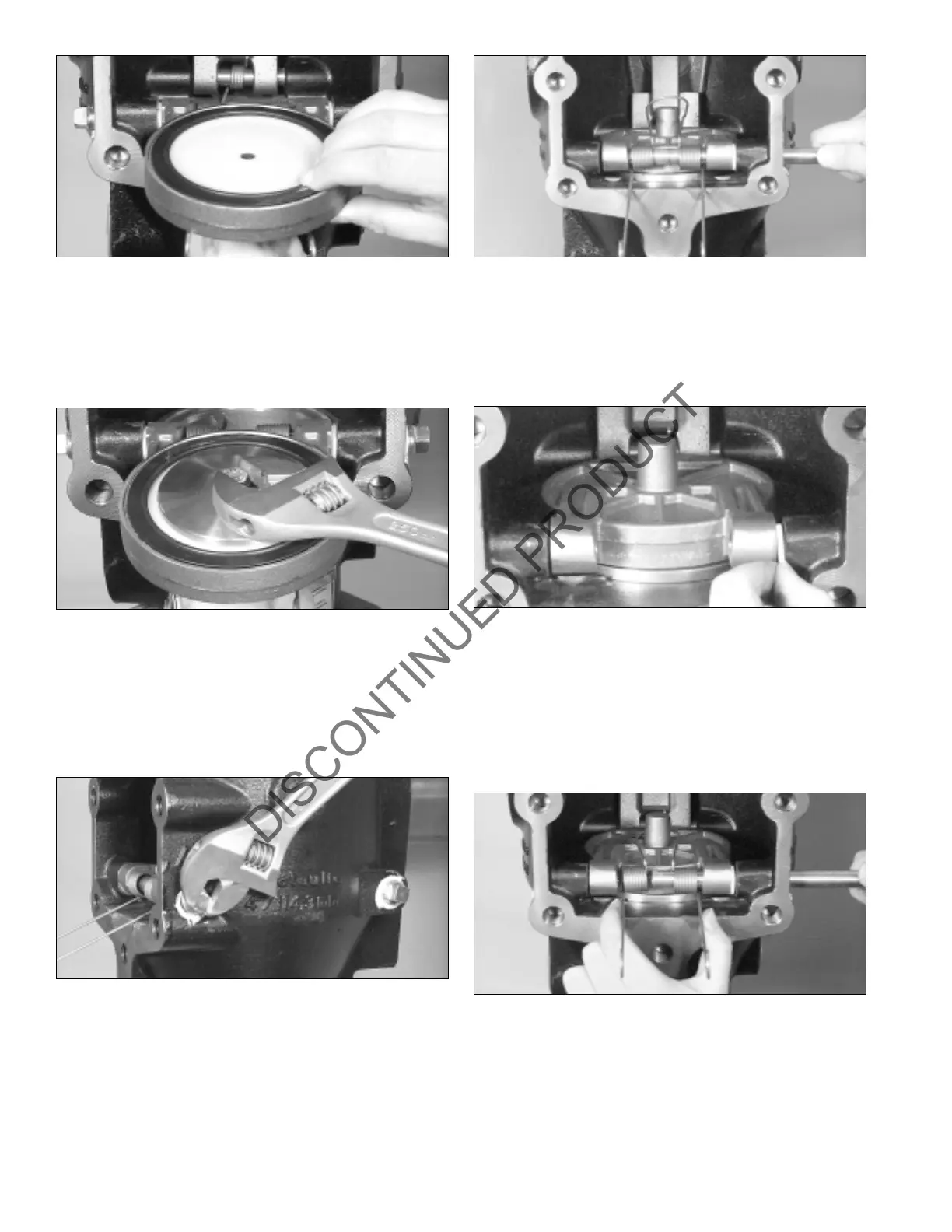

INSTALLING THE CLAPPER

1. Place the clapper on the seat ring so that the clapper

shaft can pass through both the body and the clapper.

Make sure one spacer/washer is placed on the outside of

each clapper arm.

2. Position the clapper spring so that the loop is on the

clapper and the spring coils are inside the clapper arms.

Proper positioning will allow the clapper’s shaft to pass

through the spring coils.

3. Slide the shaft through the body into the first clapper

arm, then through the clapper spring coils then out the

other clapper arm and into the body.v

Loading...

Loading...