19

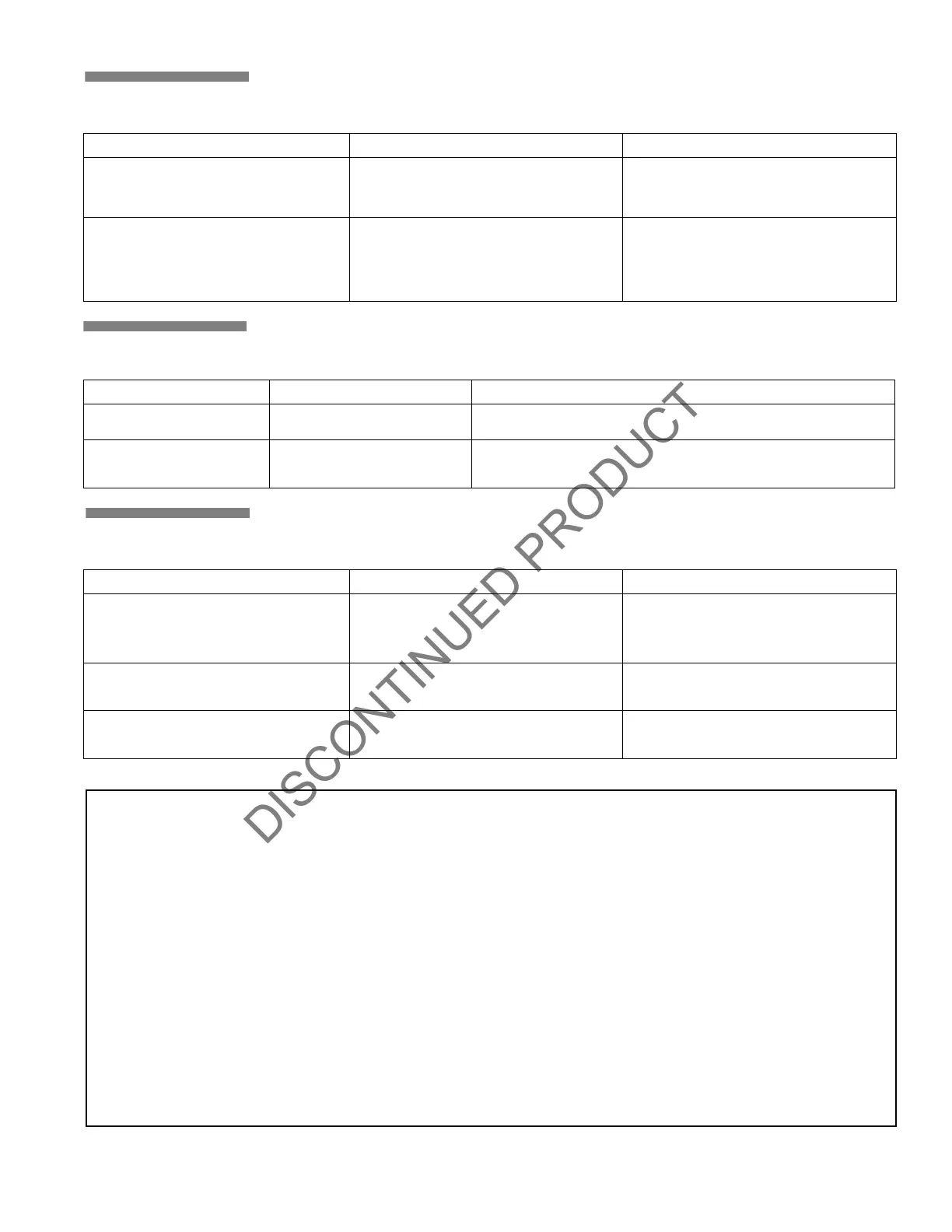

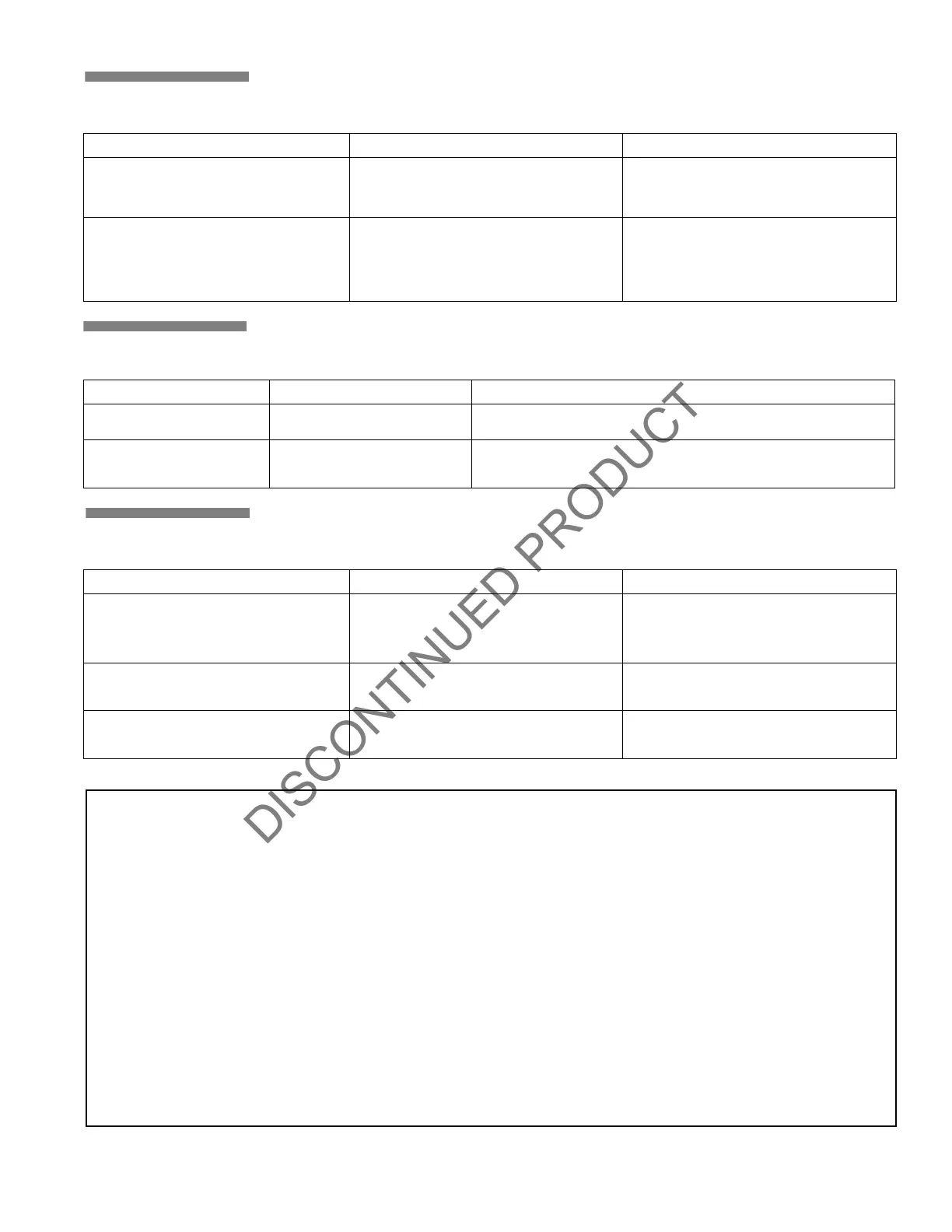

Problem Possible Cause Solution

The upper chamber seal does not engage when

pushing down on it during system setup.

The adjustable seat on the top of the actuator is set

too low.

Turn the seat with an adjustable wrench ¹⁄₄ turn

counterclockwise. Try to set the actuator again. If it

still does not set, repeat this adjustment procedure

until it does engage.

Water leaks through the actuator into the drain

when the water supply line to the piston is

opened.

The adjustable seat on the top of the actuator is set

too high.

Close the ball valve on the piston water supply line.

Open the system main drain until the Actuator

trips. Turn the seat with an adjustable wrench ¹⁄₄

turn clockwise. Set the actuator again. If it still

leaks, repeat the above procedure until it doesn’t

leak.

Problem Possible Cause Solution

The system valve operates

without sprinkler activation.

Loss of air pressure in the lower inlet

chamber.

Check for any leaks in the system and the trim. Confirm the proper operation of

the air maintenance device attached to the trim.

The dry accelerator does not

operate within a 5-psi pressure

drop in the system’s air pressure.

Loss of air pressure in the upper air

chamber of the dry accelerator.

Apply soapy water to all dry accelerator joints and check for air leaks. Repair all

leaks and re-test.

Problem Possible Cause Solution

Valve actuates when no sprinkler activation has

occurred.

Loss of air pressure in system. Check for system leaks.

Confirm the proper operation of the air

maintenance device attached to the system.

Consider installing a low air pressure alarm.

Water leaking from the ball drip. Water is getting past the seal into the intermediate

chamber.

Check the clapper rubber seal and the valve seat

ring for physical damage or the presence of a

foreign object in the seal surface.

Clapper will not latch closed. No air pressure on the dry actuator.

No water pressure on the actuator piston.

Confirm that the ball valve is open on pneumatic/

pneumatic systems and that the pressures in the

pilot line and system line are greater than 8 psi.

TROUBLESHOOTING – Series 753-A Dry Actuator

ROUBLESHOOTING – Series 746 Dry Accelerator

TROUBLESHOOTING – System

WARRANTY

We warrant all products to be free from defects in materials and workmanship under normal conditions of use and service.

Our obligation under this warranty is limited to repairing or replacing at our option at our factory any product which shall

within one year after delivery to original buyer be returned with transportation charges prepaid, and which our examination

shall show to our satisfaction to have been defective.

THIS WARRANTY IS MADE EXPRESSLY IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THE BUYER’S SOLE AND

EXCLUSIVE REMEDY SHALL BE FOR THE REPAIR OR REPLACEMENT OF DEFECTIVE PRODUCTS AS PROVIDED

HEREIN. THE BUYER AGREES THAT NO OTHER REMEDY (INCLUDING, BUT NOT LIMITED TO, INCIDENTAL OR CON-

SEQUENTIAL DAMAGES FOR LOST PROFITS, LOST SALES, INJURY TO PERSON OR PROPERTY OR ANY OTHER INCI-

DENTAL OR CONSEQUENTIAL LOSS) SHALL BE AVAILABLE TO HIM.

Victaulic neither assumes nor authorizes any person to assume for it any other liability in connection with the sale of such

products.

This warranty shall not apply to any product which has been subject to misuse, negligence or accident, which

has been repaired or altered in any manner outside of Victaulic's factory or which has been used in a manner

contrary to Victaulic’s instructions or recommendations. Victaulic shall not be responsible for design errors

due to inaccurate or incomplete information supplied by Buyer or its representatives.

EFFECTIVE OCTOBER 15, 1997

Loading...

Loading...