6

AIR MAINTENANCE TRIM

Proper Air Supplies for

Series 758 Preaction

Valves:

1. When a riser or base-

mounted air compressor

supplies air to a system

utilizing a Series 753-A Dry

Actuator, it is not necessary to

use the air maintenance trim

assembly with the air

regulator. In this

circumstance, the airline of

the compressor connects to

the valve’s trim at the fitting

where the air maintenance

trim is normally installed.

When the valve is used with

this setup, it is the engineer’s/

system designer’s

responsibility to size the

compressor so that it brings

the entire system to the

required pressure within 30

minutes. The engineer/system

designer must not oversize the

compressor to provide more

airflow because it will slow

down, or possibly prevent, the

operation of the valve.

Furthermore, a base-mounted

compressor does not provide

any backup air to the system.

Therefore, the system requires

continuous service (24 hours

per day, 7 days per week) in

order to prevent the valve from

false tripping due to a loss of

air pressure.

Due to the large on/off

differential available on

pressure switches that control

base-mounted compressors,

you must adjust the

compressor pressure switch so

that the “ON” contact of the

pressure switch is at the

recommended air supply for

the valve.

2. When shop air or a tank-

mounted air compressor is

used, you must use Victaulic

Company’s Air Maintenance

Trim Assembly (AMTA). The

AMTA provides the proper air

regulation to the sprinkler

system, which will ensure the

proper operation of the fire

safety valve.

3. When a Series 746 Dry

Accelerator is used in

conjunction with the Series

753-A Dry Actuator, you must

use the AMTA with the air

regulator.

In the event that a compressor

becomes inoperative, the

tank-mounted air compressor

provides the greatest

protection. With a properly

sized tank, air can be supplied

continuously to the sprinkler

system for an extended time,

even without an operating

compressor.

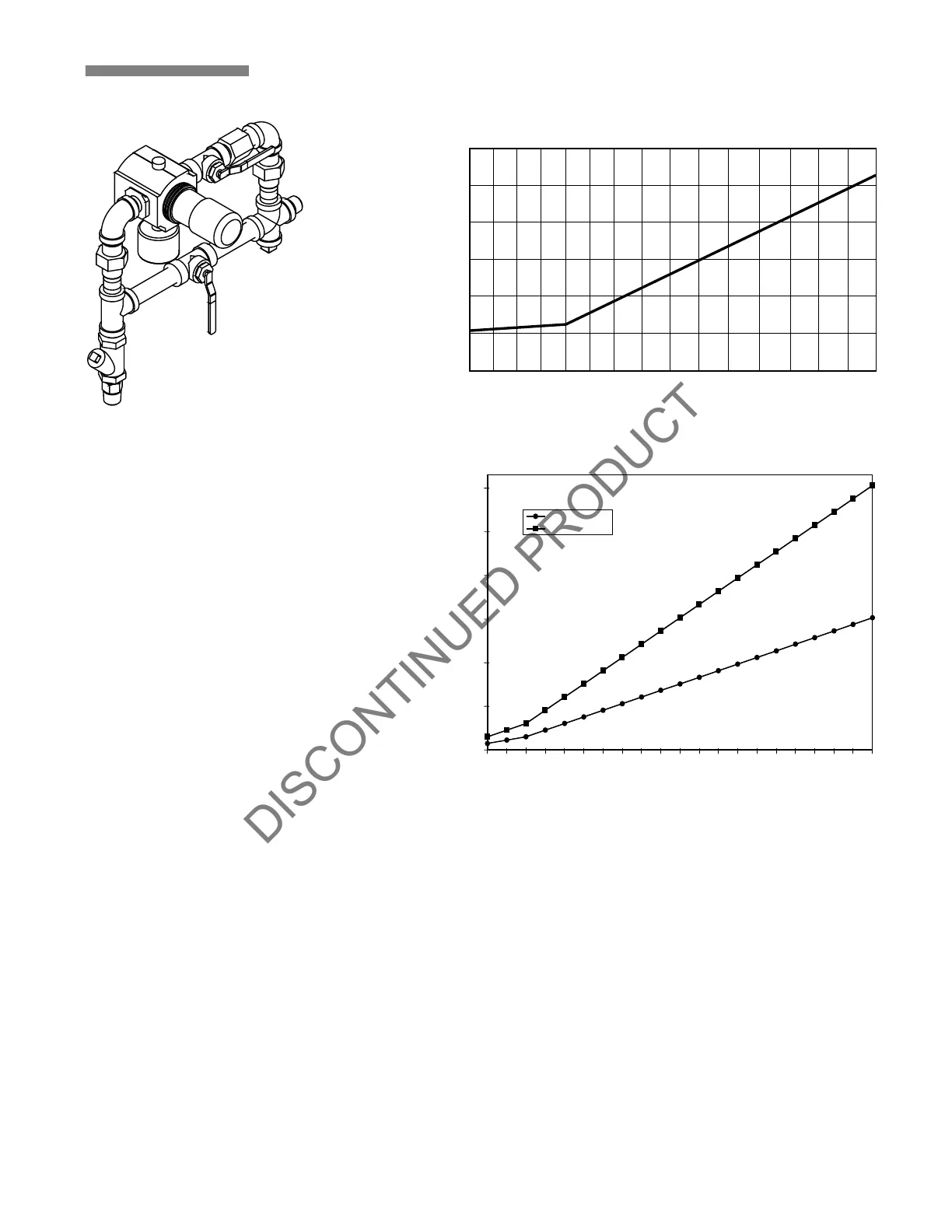

COMPRESSOR REQUIREMENTS

0.0

2.0

4.0

6.0

8.0

10.0

12.0

SYSTEM CAPACITY (GAL.)

REQUIRED FLOW RATE (CFM)

20 PSI System Air

40 PSI System Air

50 75 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000

AIR PRESSURE – PSI

MAXIMUM WATER SUPPLY PRESSURE - PSI (Peak)

RECOMMENDED AIR PRESSURE FOR DRY AND PNEUMATIC ACTUATED SYSTEMS

60

50

40

30

20

10

0

5 10 15 20 25 50 75 100 125 150 175 200 225 250 275 300

NOTES:

1) You must use an air

regulator with Series 758

Preaction Valves that utilize an

accelerator.

2) The recommended air

pressures shown on the chart

apply to valves utilizing a

Series 753-A Dry Actuator.

These pressures involve an 8

to 1 water-to-air ratio, plus a

ten-pound safety factor.

3) If you install systems with

multiple, pneumatic-actuated

valves, isolate the systems by

using a spring-loaded, soft

seat check valve to ensure air

integrity to each system.

Loading...

Loading...