5461 889 - 16

34

Vitodens 222-F, B2TB 19, 35, 68, 125 Installation

Installation Examples

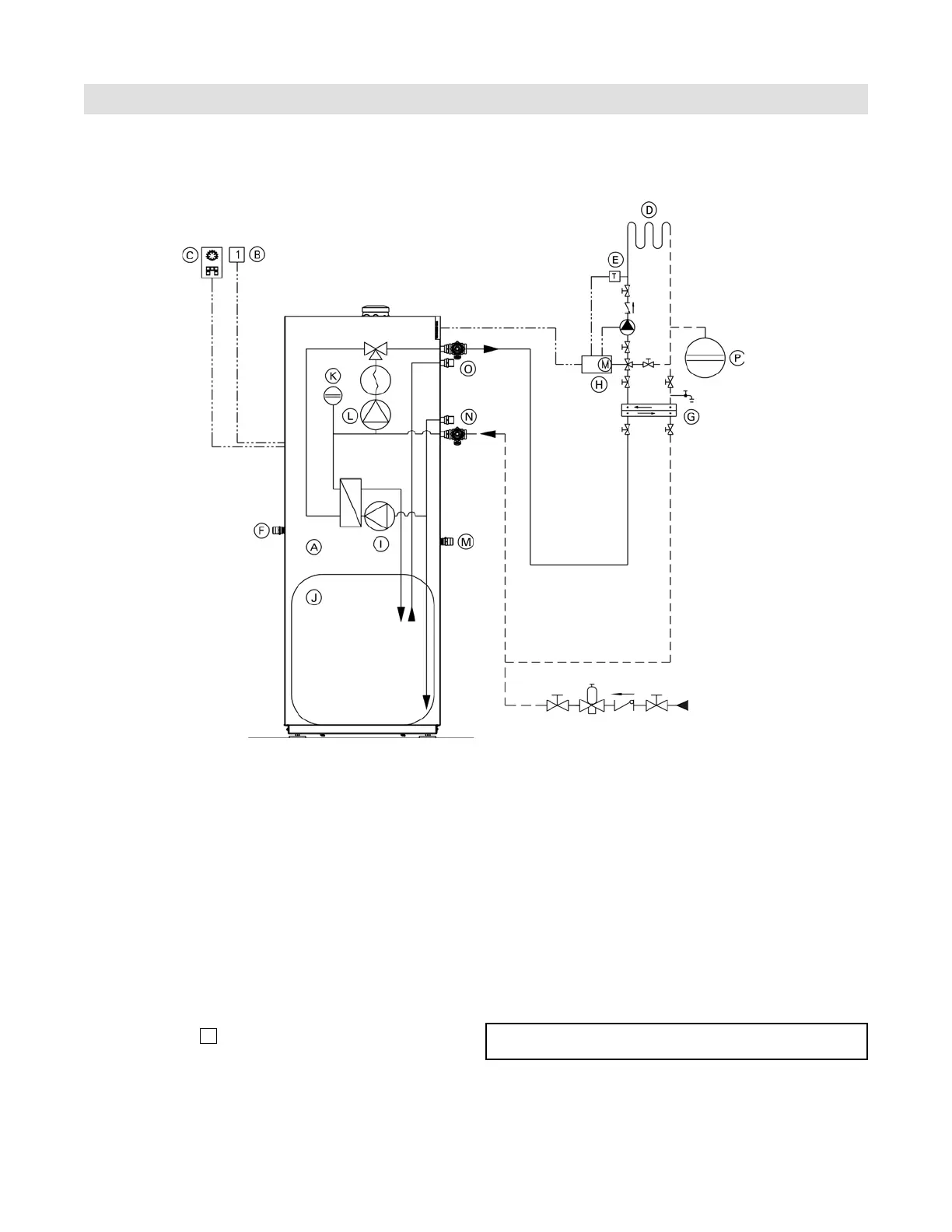

System Layout 3

Vitodens 222-F, B2TB with...

- Integrated DHW production

- one heating circuit with mixing valve and system separation

Installation of ...

■ underfloor heating circuit with 3-way mixing valve

and system separation (low-temp. circuit)

■ DHW production

... with the following flow conditions:

The flow rate of the heating circuit is less than the

maximum possible water flow rate of the Vitodens

222-F B2TB boiler.

See page 30 for maximum water flow rate of the Vitodens

222-F B2TB boilers. The use of a low-loss header is

recommended if the system water flow rate is unknown.

The low-loss header is available as accessory part.

See following pages for installation examples with a

low-loss header.

System separation is required of underfloor heating

systems employing non-oxygen diffusion barrier tubing.

All components on the secondary side of the heat

exchanger must be made of corrosion-resistant materials.

IMPORTANT

Legend

A Vitodens 222-F B2TB boiler with

Vitotronic 200, HO1B outdoor reset

control

B Outdoor temperature sensor !

C Vitotrol remote (optional)

D Underfloor heating circuit

E Mixing valve temperature sensor ?

F Pressure relief valve outlet

G Plate heat exchanger for system

separation

H Accessory kit for heating circuit with

mixing valve

I DHW circulating pump sA

J DHW storage tank

K Integral expansion tank

L Boiler pump 20

M Temperature and pressure relief valve outlet

N DCW inlet

O DHW outlet

P Expansion tank

Loading...

Loading...