165

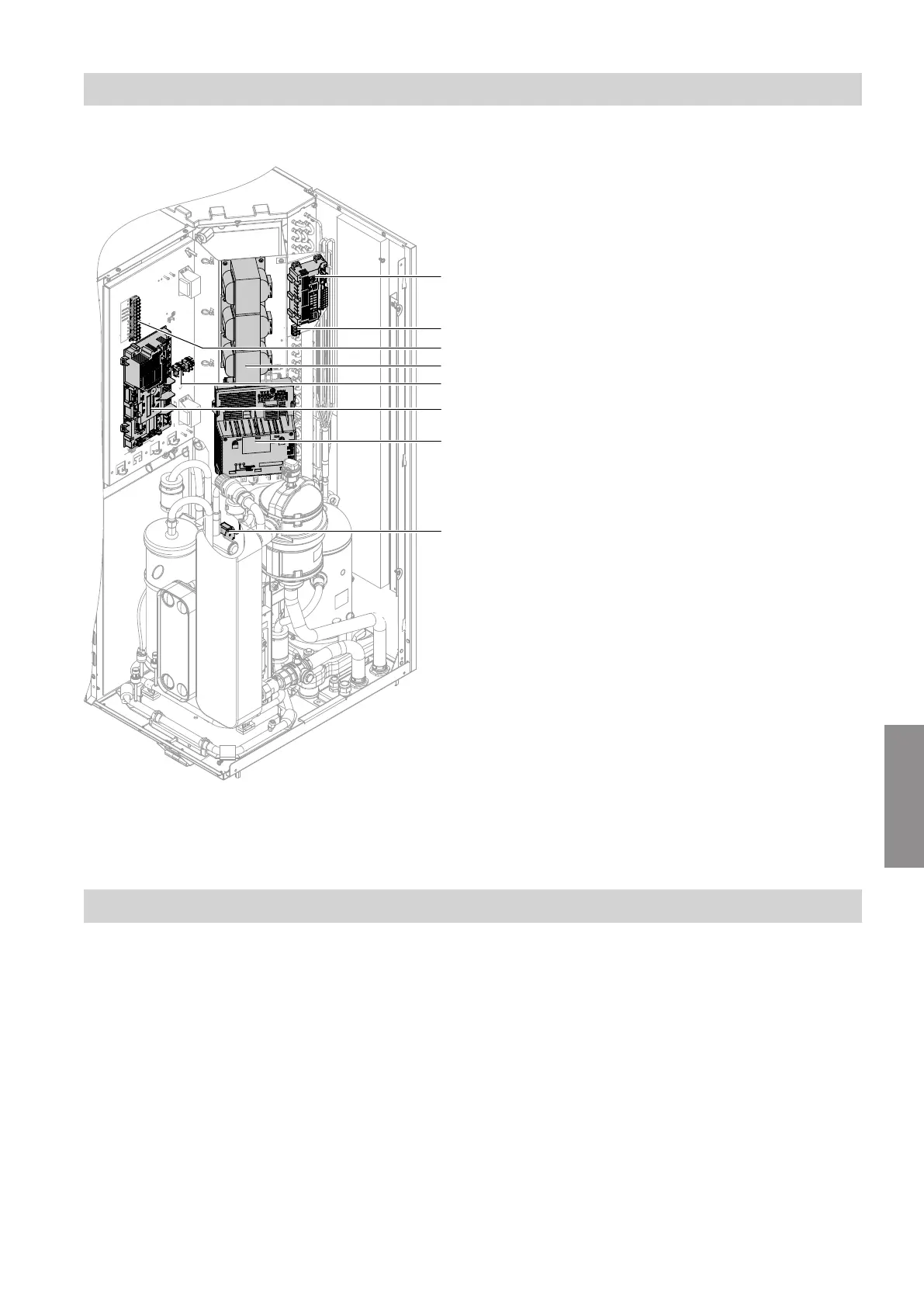

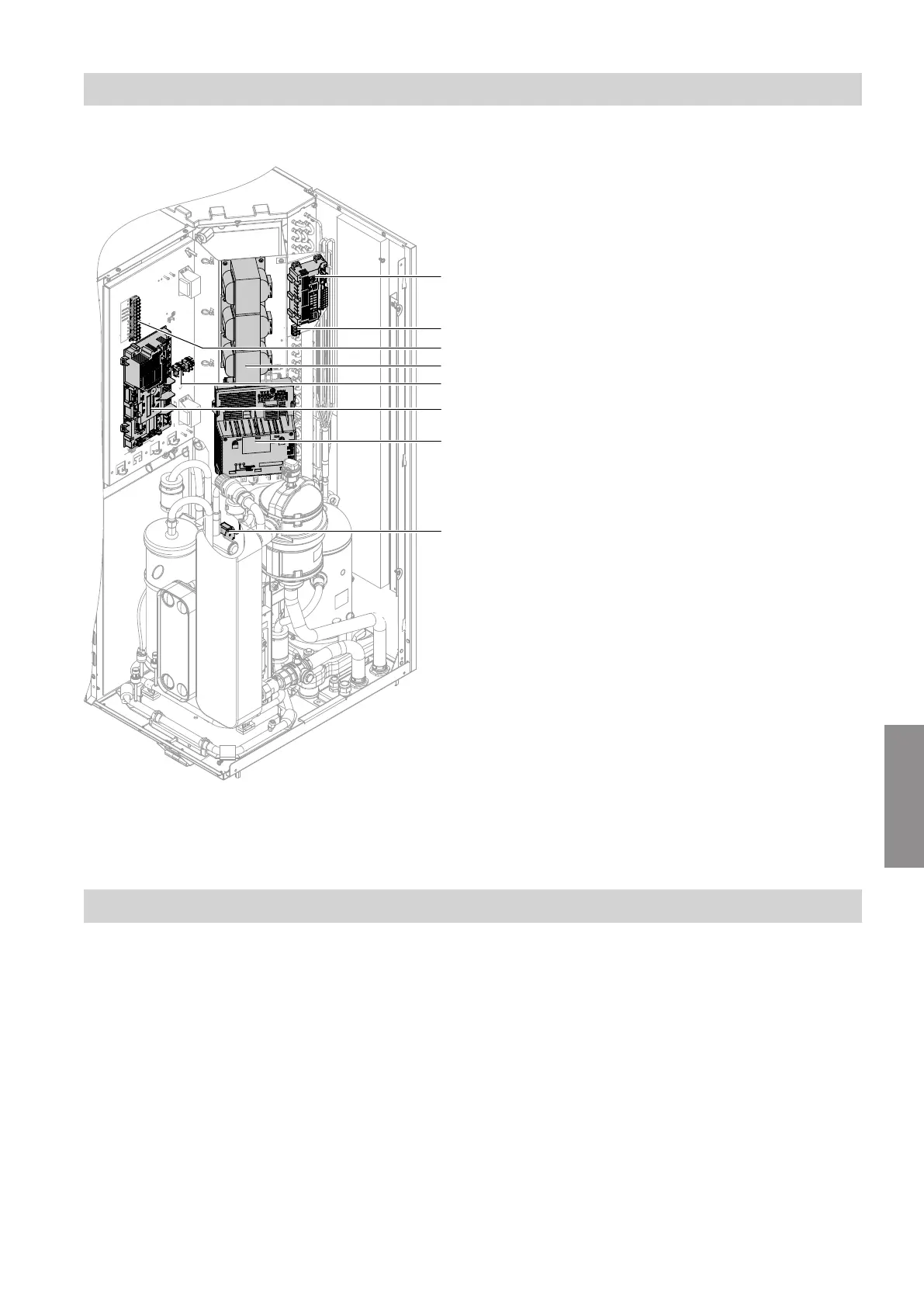

Outdoor unit with 2 fans, types ...A16 to A19

Fig. 114

A

EMCF PCB with 400 V~ power supply

B

Connection for CAN bus communication cable

C

Terminal strip, 230 V~ function components

D

Chokes

E

Fuses for PCB and fans

6.3 A H (slow), 250 V~

F

VCMU refrigerant circuit controller

G

Inverter

H

Coil, 4-way diverter valve

Checklist for maintenance work

Note

Work on the refrigerant circuit must only be carried out

by Viessmann Technical Services employees.

■

Every person working on the refrigerant circuit must

be able to produce a certificate of competence

issued by an organisation with industry accreditation.

This certificate confirms their competence in the safe

handling of refrigerants by means of a standard

industry procedure.

■

Servicing work may only carried out in accordance

with the manufacturer's specifications. If mainte-

nance and repair work requires assistance from

additional individuals, the person trained in the han-

dling of flammable refrigerants must constantly

supervise the work.

■

For soldering work on the refrigerant circuit, only sol-

ders AG145 and CuP 281a may be used. These are

used by Viessmann and comply with ISO 17672.

■

In order to minimise the risk of ignition, safety checks

must be carried out before any work on appliances

with flammable refrigerants can commence. Take the

following measures before interfering with the refrig-

erant circuit:

Outdoor unit maintenance

Overview of electrical components (cont.)

6222080

Maintenance

Loading...

Loading...