77

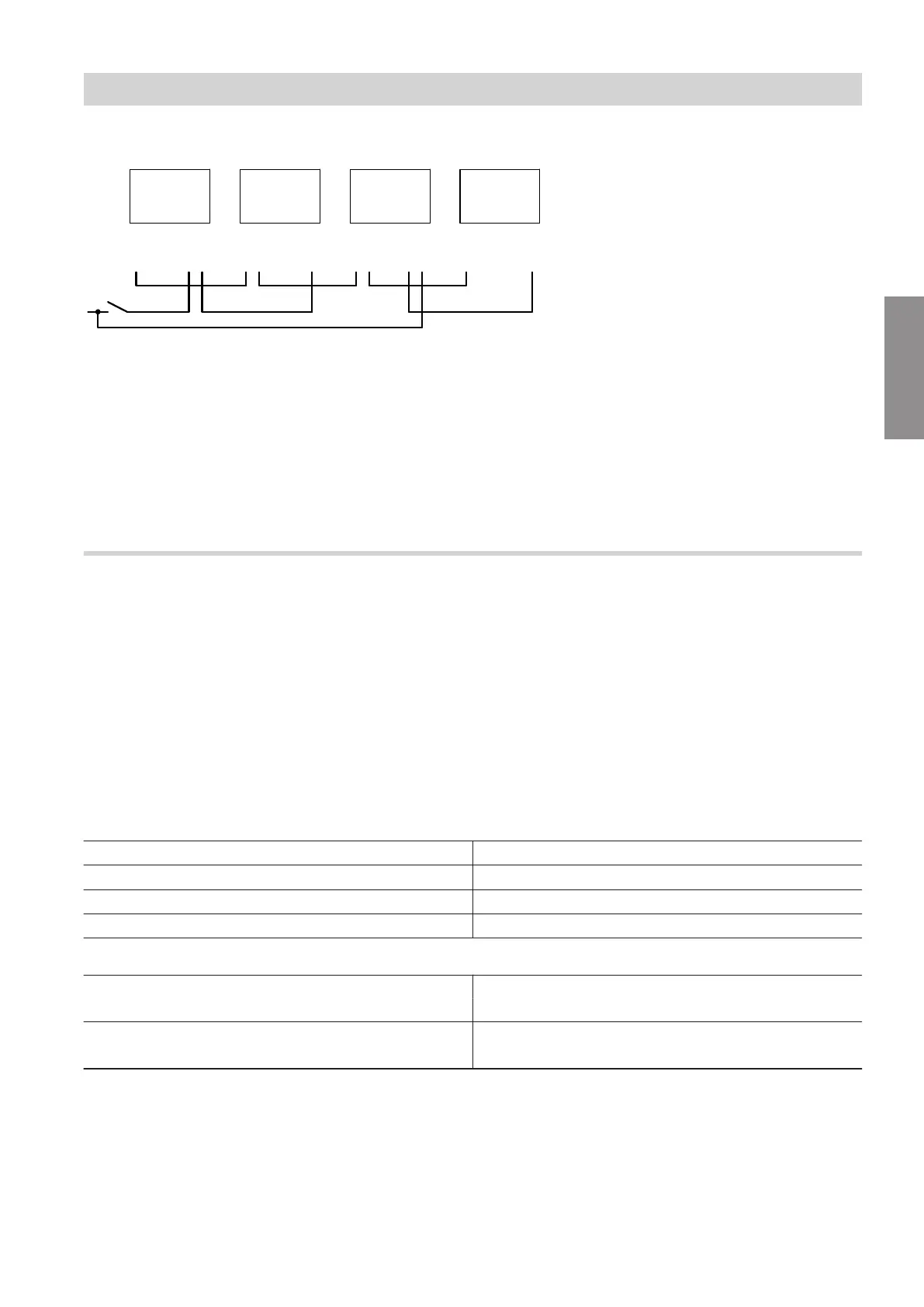

Some accessories with direct power supply

74

74

40A

40

74

74

40A

40

B C

74

40

156

A

74

74

40A

40

D

E

Fig. 57

A

Indoor unit terminal areas

40 Control unit/PCB power supply in the 230 V~

terminal area

74 Connecting PlusBus to the upper luster termi-

nal in the low voltage (ELV) < 42 V terminal

area

156 Power supply for PlusBus subscribers in the

HPMU electronics module

B

Mixer extension kit

C

Mixer extension kit

D

Mixer extension kit

E

ON/OFF switch

Connecting with other Viessmann appliances via the CAN bus

The heat pump can form a system network with other

compatible appliances via the external CAN bus. Com-

bining Viessmann appliances with One Base brings

benefits such as shared use of a connectivity module

or even joint commissioning and operation via an app.

■

The Viessmann CAN bus is designed for "line" bus

topology with a terminator at both ends: See Fig. 58.

■

With CAN bus, the transmission quality and the

cable lengths depend on the electrical properties of

the cable.

■

Only use one cable type within a CAN bus.

Note

Commissioning of all CAN bus subscribers: See chap-

ter "Commissioning the system".

Recommended cable

■

Recommended cable:

Bus cable (accessories), length: 5, 15 or 30 m

■

For wiring on site:

Only use cable types listed in the following tables.

Recommended cable type (on site):

CAN bus cable In line with ISO 11898-2, twisted pair cable, shielded

■

Cable cross-section

0.34 to 0.6 mm

2

■

Characteristic impedance 95 to 140 Ω

■

Max. length (entire CAN bus system) 200 m

Alternative cable types (on site):

CAN bus cable 2-core, CAT7, shielded

■

Max. length (entire CAN bus system) 200 m

CAN bus cable 2-core, CAT5, shielded

■

Max. length (entire CAN bus system) 200 m

Terminator for external CAN bus system

When integrating into an external CAN bus system, a

distinction is made as to whether a CAN bus sub-

scriber is the first, last or central subscriber.

In order to avoid communication interferences, only

1 terminator with 120 Ω may be present at the first and

last subscriber for the termination of the external CAN

bus system.

If the heat pump is connected as the central sub-

scriber, the factory-connected terminator must be

removed: See the following chapters.

Electrical connections

Electrical connection of the indoor unit (cont.)

6222080

Installation

Loading...

Loading...