Software Installation and Connections 21

© 2015 Vision Engraving Systems

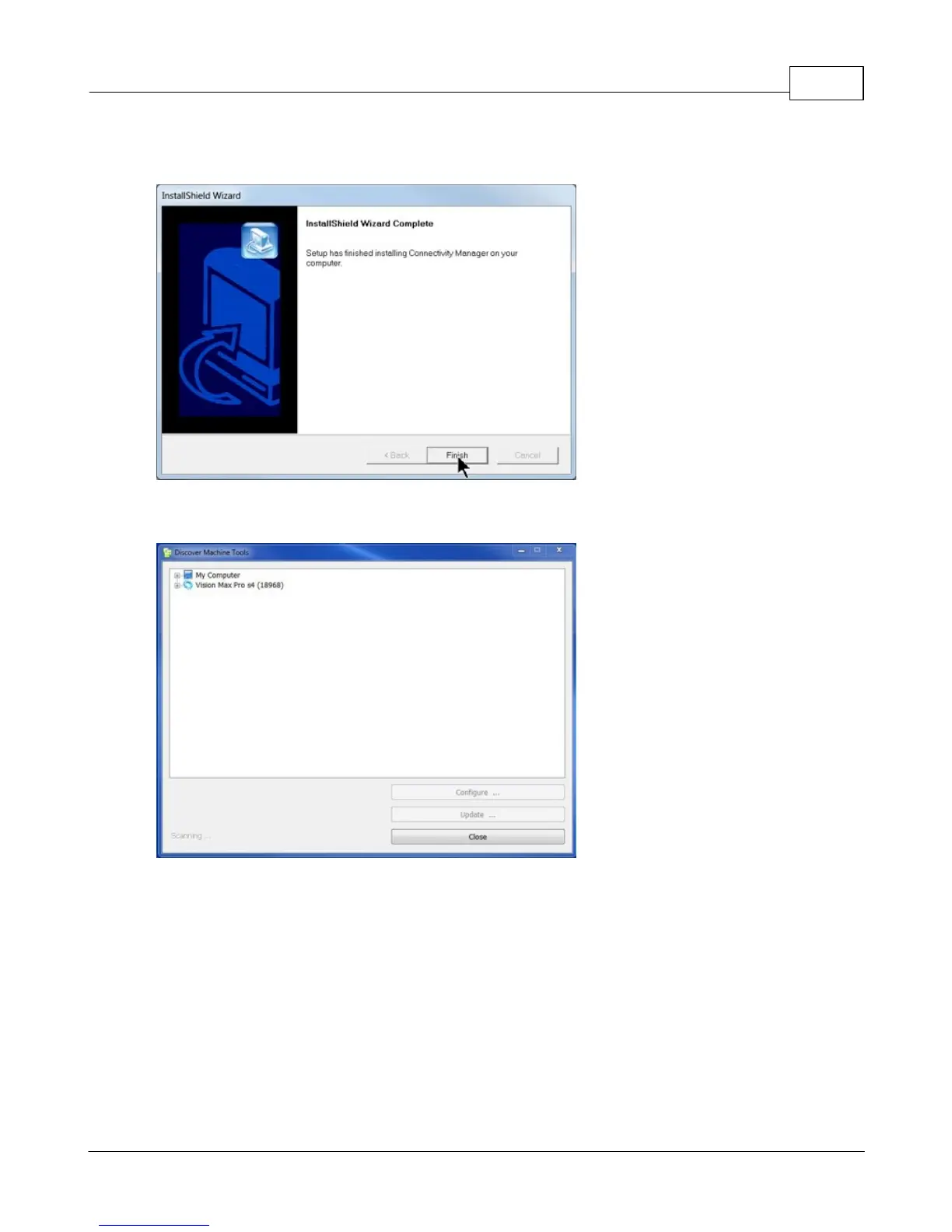

When the software is installed, select Finish.

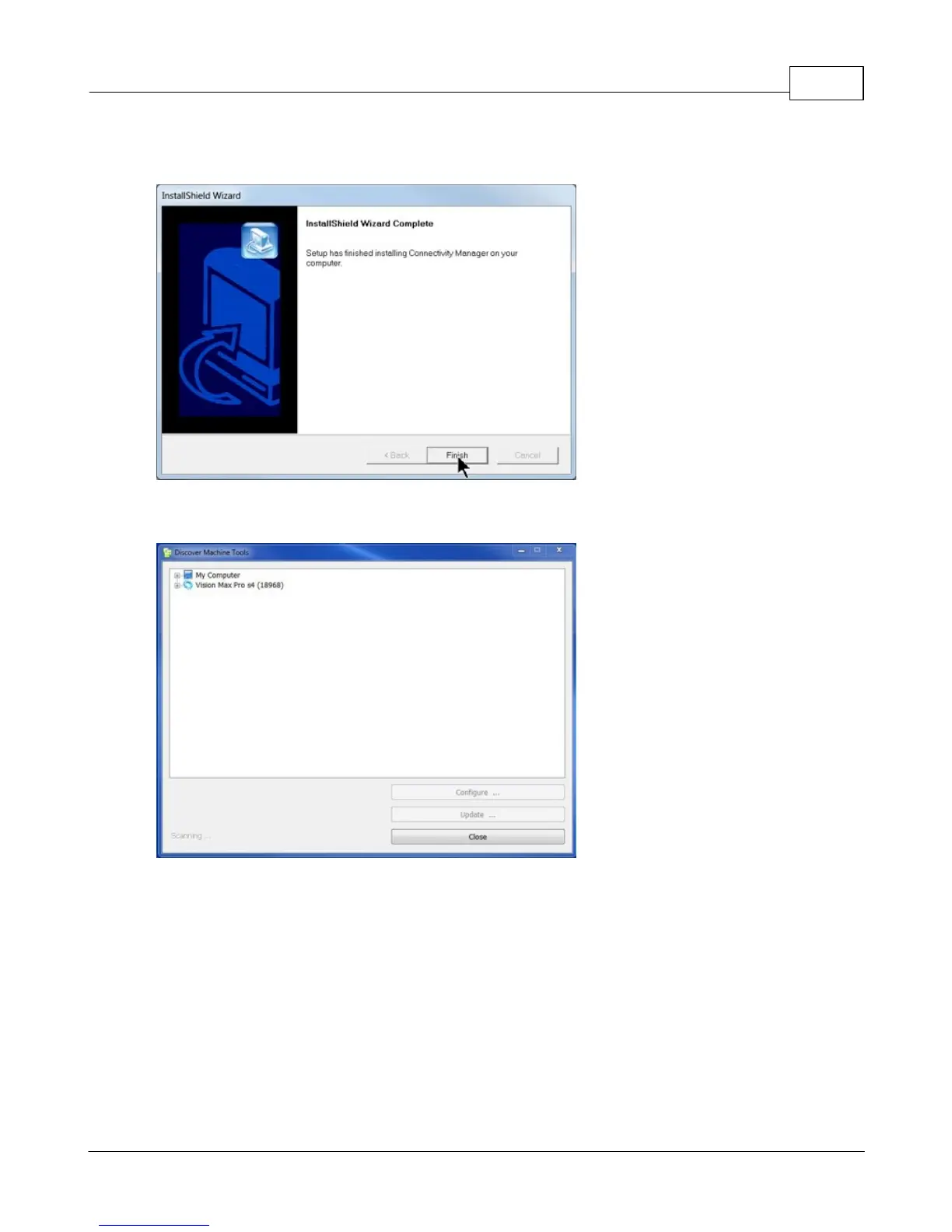

The Connectivity Manager will search for available Vision devices.

The configuration is complete at this point. Close the Machine Tools Discovery window and return to

the Main Installation Screen to proceed with the Vision software installation in the next section.

Loading...

Loading...