Group 25 Intake and Exhaust System Service Procedures

3

W2000734

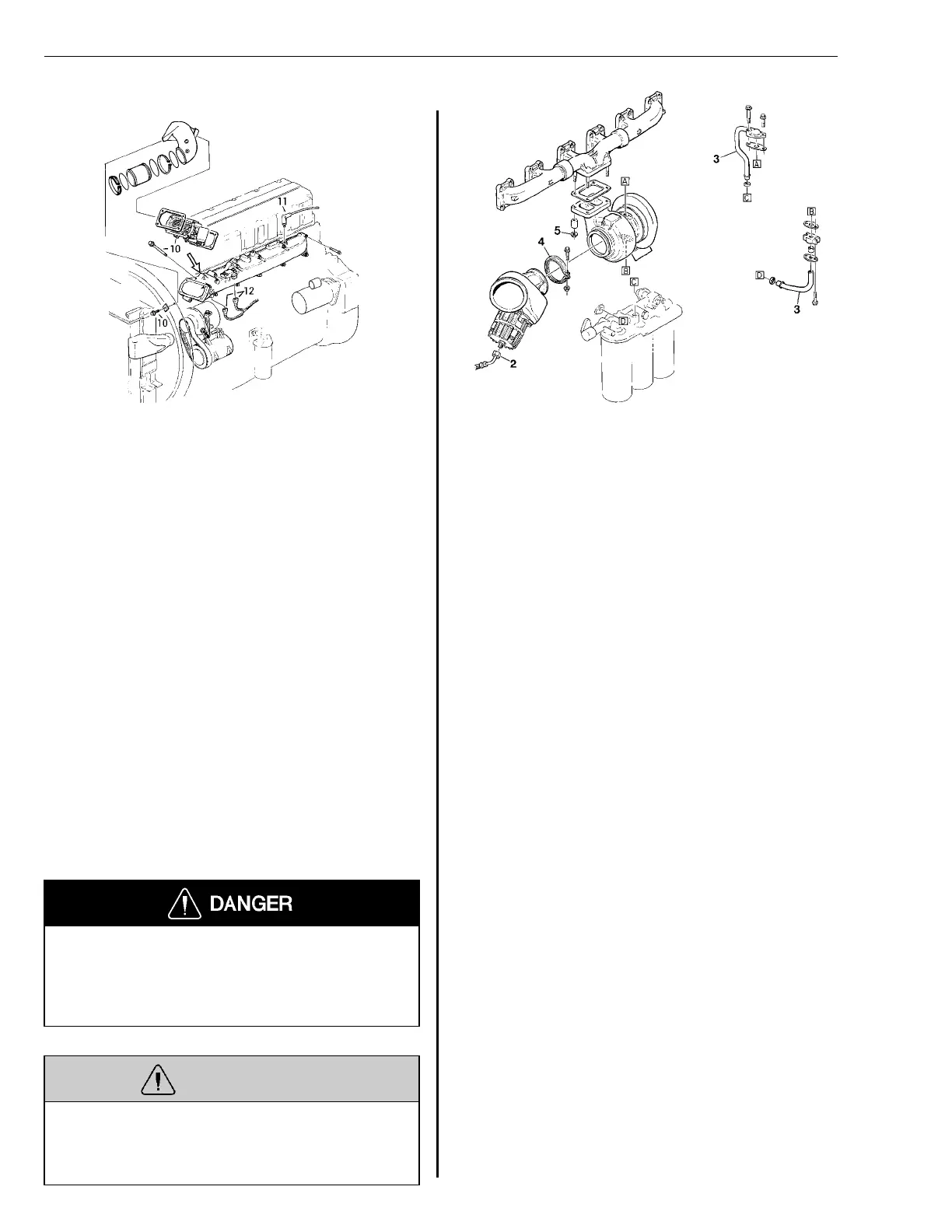

Fig. 37: Replacing intake manifold gasket

Adjust the alternator, A/C refrigerant

compressor, drive belt tension if so

equipped.

4

Install the pre-heater (if equipped) or

the spacer, using new gaskets, and

bolt the mounting to the fan shroud.

5

Install the boost air gauge connections

to the intake manifold.

6

Reconnect the terminals to the sen-

sors for the boost air pressure and the

boost air temperature on the intake

manifold. Tie the electrical cables.

2551-03-02-02

Turbocharger, Replacement

Before working on a vehicle, set the parking brakes,

place the transmission in neutral, and block the

wheels. Failure to do so can result in unexpected

vehicle movement and can cause serious personal in-

jury or death.

WARNING

HOT ENGINE! Keep yourself and your test equipment

clear of all moving parts or hot engine parts and/or

fluids. A hot engine and/or fluids can cause burns or

can permanently damage test equipment.

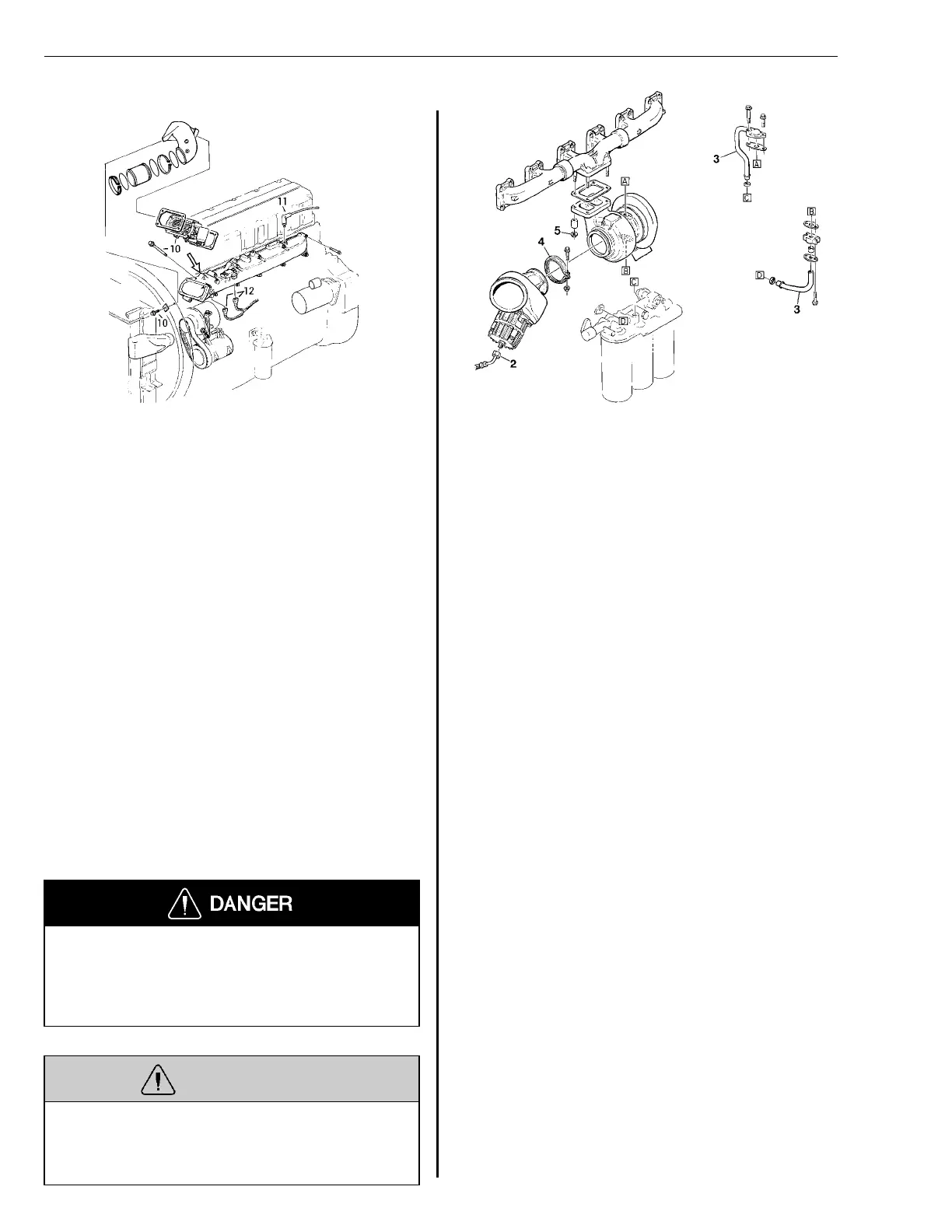

W2000943

Fig. 38: Turbocharger assembly

1 n/a

2 Exhaust pressure governor

3 Oil delivery and return pipes

4 Clamp

5 Nuts

General Guidelines and Precautions

Always determine the reasons for replacing a tur-

bocharger before making the repair. Correct any noted

defects before replacing.

When replacing a turbocharger, always thoroughly read

and carefully follow the procedures.

After degreasing, wipe the cooler clean and dry it with

compressed air. Also check the air pipes and charge air

hose. If contaminated with oil, replace the charge air

hose to prevent damage to the rubber.

The engine oil system and intake system must be kept in

good condition to ensure proper turbocharger operation.

That is, change oil and filters at specified times, use the

correct engine oil and properly care for the air cleaner.

When replacing a turbocharger, use compressed air to

remove any rust or carbon flakes from the exhaust mani-

fold. Carbon flakes can damage the turbine of the new

unit. It is also important to clean the intake pipe from the

air filter. Pieces of broken components can remain in the

pipe and cause immediate turbocharger failure.

Also, always check to be sure that the injection equip-

ment is in good condition.

Note: Once the turbocharger is installed put oil in oil

supply port to ensure proper turbo lubrication. Once

turbo is sufficently lubricated you can crank the engine.

Removal

1

Remove the air cleaner hose from the

turbocharger.

32

Loading...

Loading...