Group 25 Intake and Exhaust System System Check

System Check

2559-06-02-02

Boost Pressure, Checking

Note: This operation number covers only the installation

and removal of test equipment.

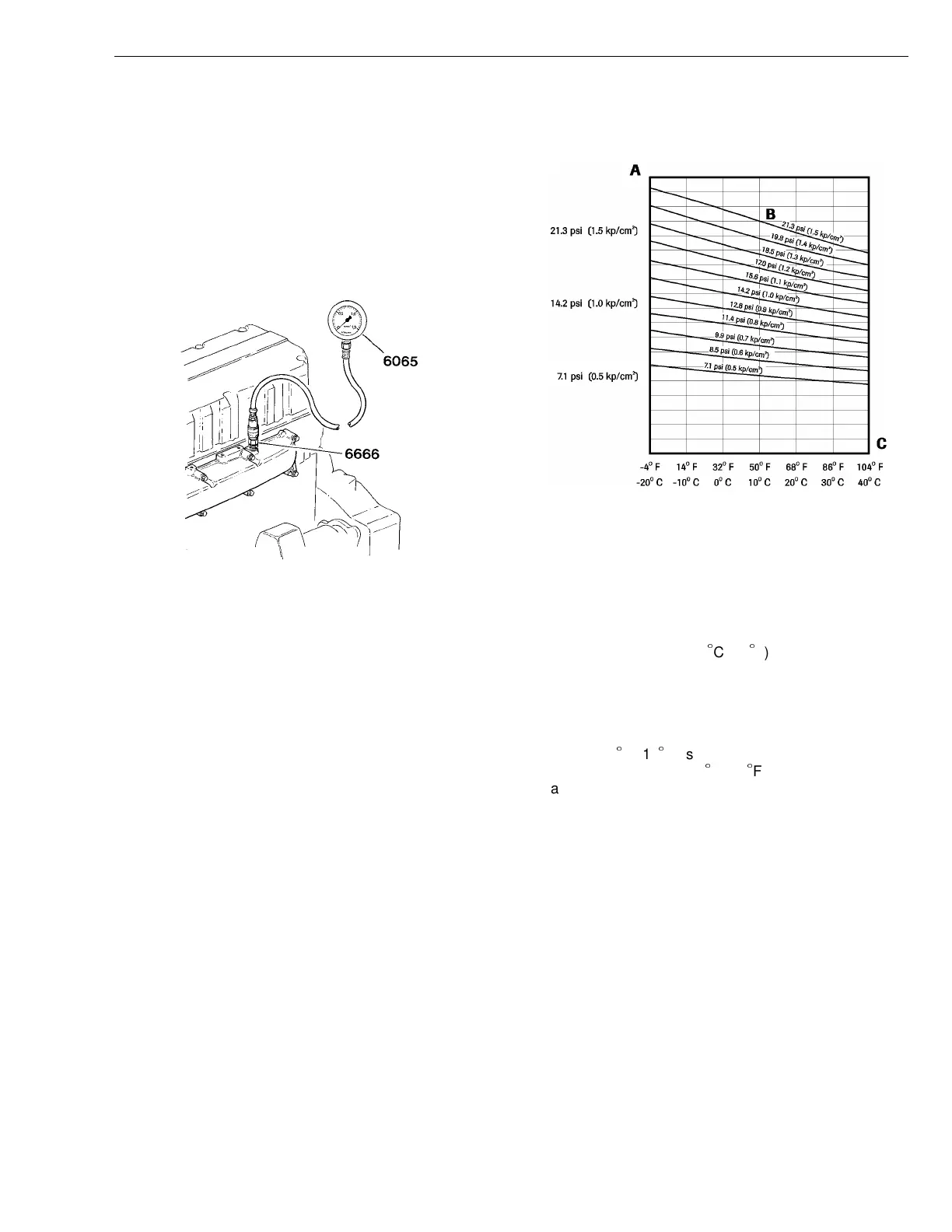

Special tools: 9996065, 9996666

1

T2006943

Boost pressure gauge installation

Clean around the plug for the boost

pressure gauge on the intake mani-

fold. Remove the plug and install

union 9996666. Connect pressure

gauge 9996065 to the 9996666 union.

Make sure the pressure gauge hose is

long enough to reach the driver’s seat

in the cab.

Note: Secure the hose so that it does

not contact any moving parts.

2

The measurement should be carried

out:

•

with a fully loaded vehicle

•

driving up an incline at full accel-

eration (full load)

•

while engine revs (rpm), slowly

pass the speed specified for boost

pressure.

Note: For a reliable result, engine load

must be maintained long enough for

the pressure to stabilize. Boost pres-

sure specifications at 28.3 r/s (1700

rpm):

•

VE D12–370 125–170 kPa (18–24.7 psi)

•

VE D12–415 145–175 kPa ( 21–25.4 psi)

3

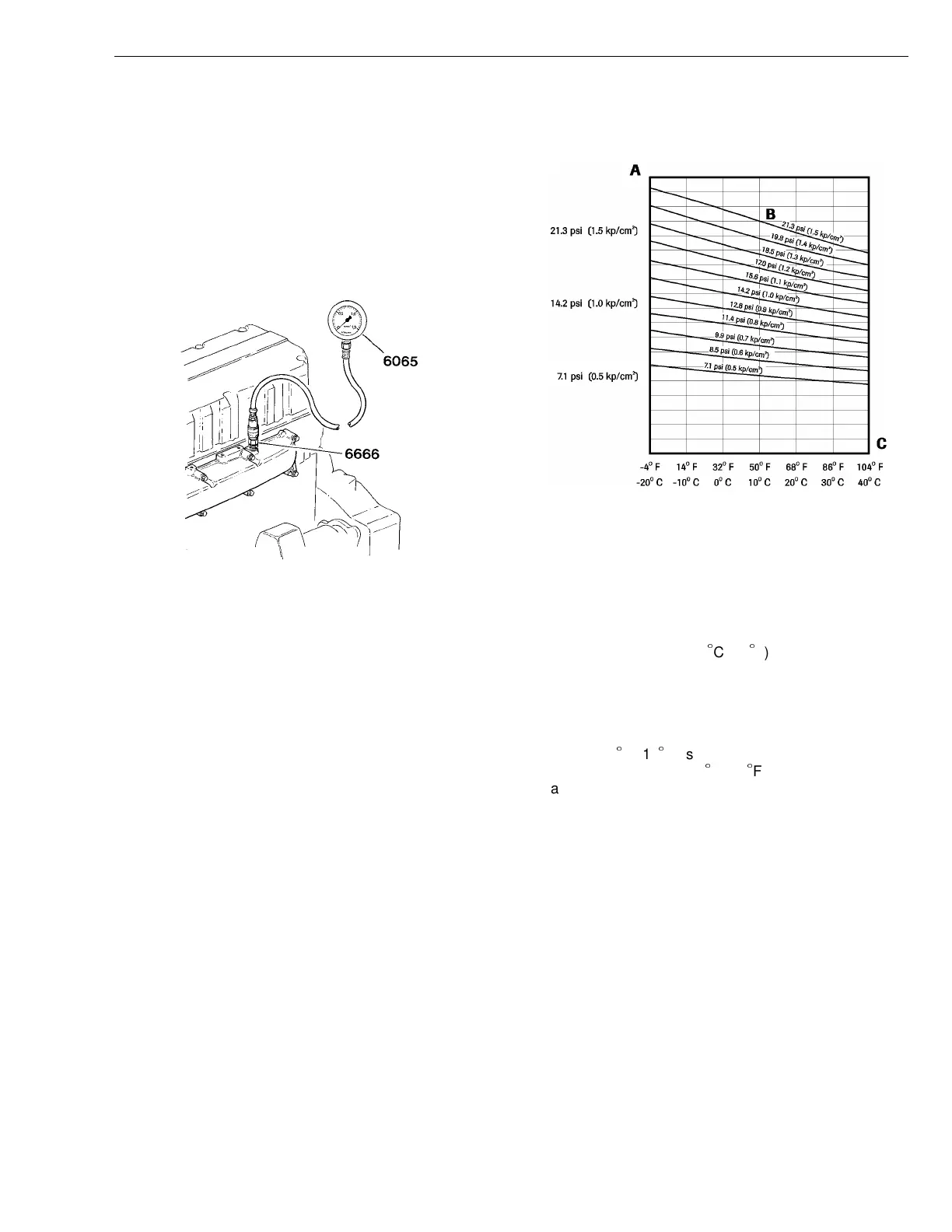

W2000737

Boost pressure at various temperatures

A measured boost pressure

B correction curves

C intake air temperature

The specifications state engine speed

and boost pressure at +20

C (68

F). If

reading at any other temperature, use

the chart above to correct the resulting

boost pressure.

Example:

A pressure of 80 kPa (12 psi) mea-

sured at –10

C (14

F) is equivalent to

about 70 kPa (10 psi) +20

C (68

F).

That is, pressure drops as tempera-

ture rises.

If boost pressure does not reach spec-

ified levels, check the following:

•

properly tightened bolts on intake

and exhaust manifolds

•

exhaust brake

•

backpressure in exhaust system

•

air cleaner element

•

fuel pressure

41

Loading...

Loading...