Group 25 Intake and Exhaust System System Check

Exhaust Backpressure, Checking

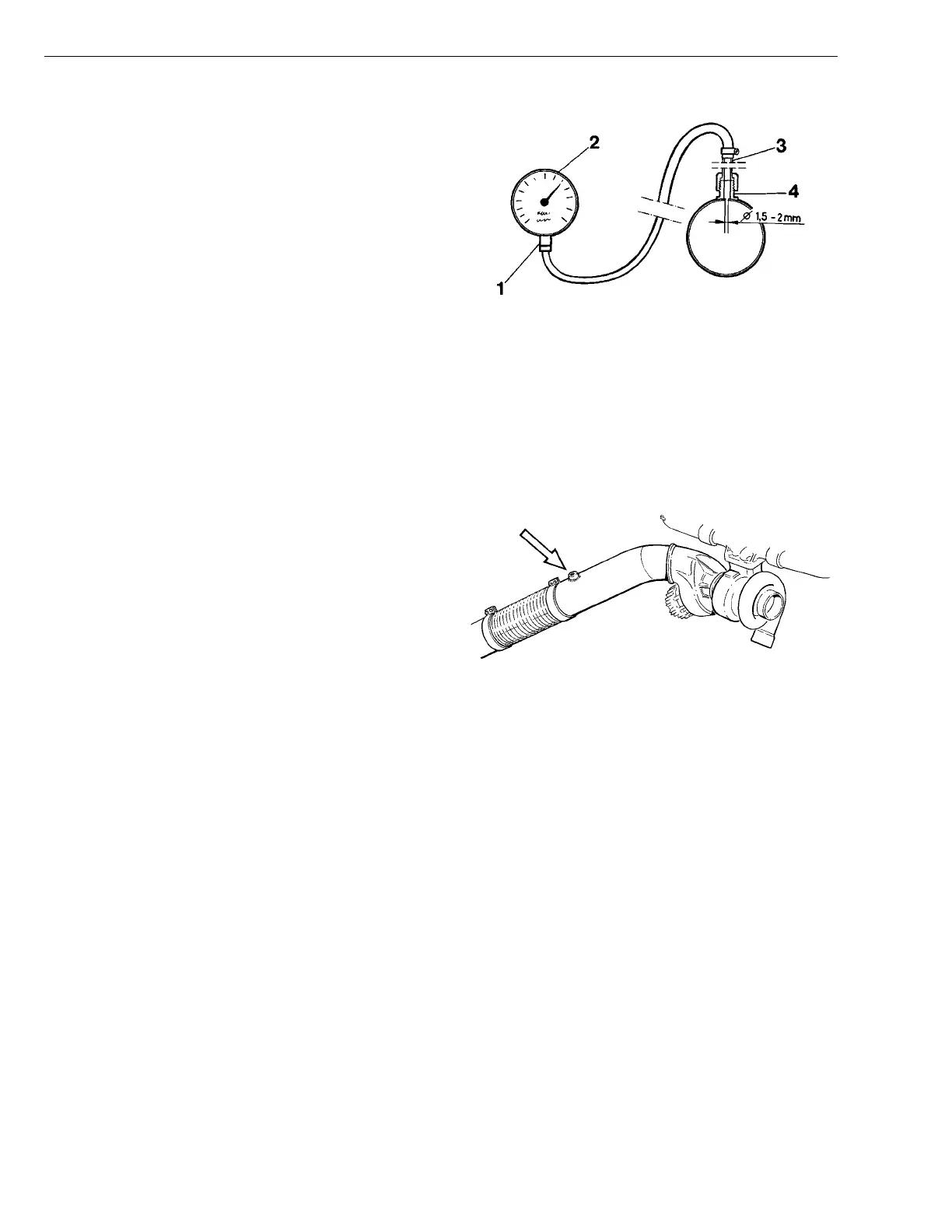

Pressure gauge: Of indicating or U-tube type, graded to

24 kPa or 2,440 mm water column (3.5 psi) and

equipped with damper.

Steel pipe: About 200 mm (8 in.) long and able to con-

nect to a union.

Union: The union must be brazed onto the exhaust pipe

as shown. Then drill a 1.5 – 2.0 mm (0.06 – 0.08 in)

hole through the center of the union and the side of the

exhaust pipe.

Hose: The hose is installed between the pressure gauge

and steel pipe and must be long enough for the gauge to

be read inside the cab.

T2006988

Measuring equipment

1 Damper

2 Pressure gauge

3 Steel pipe

4 Union

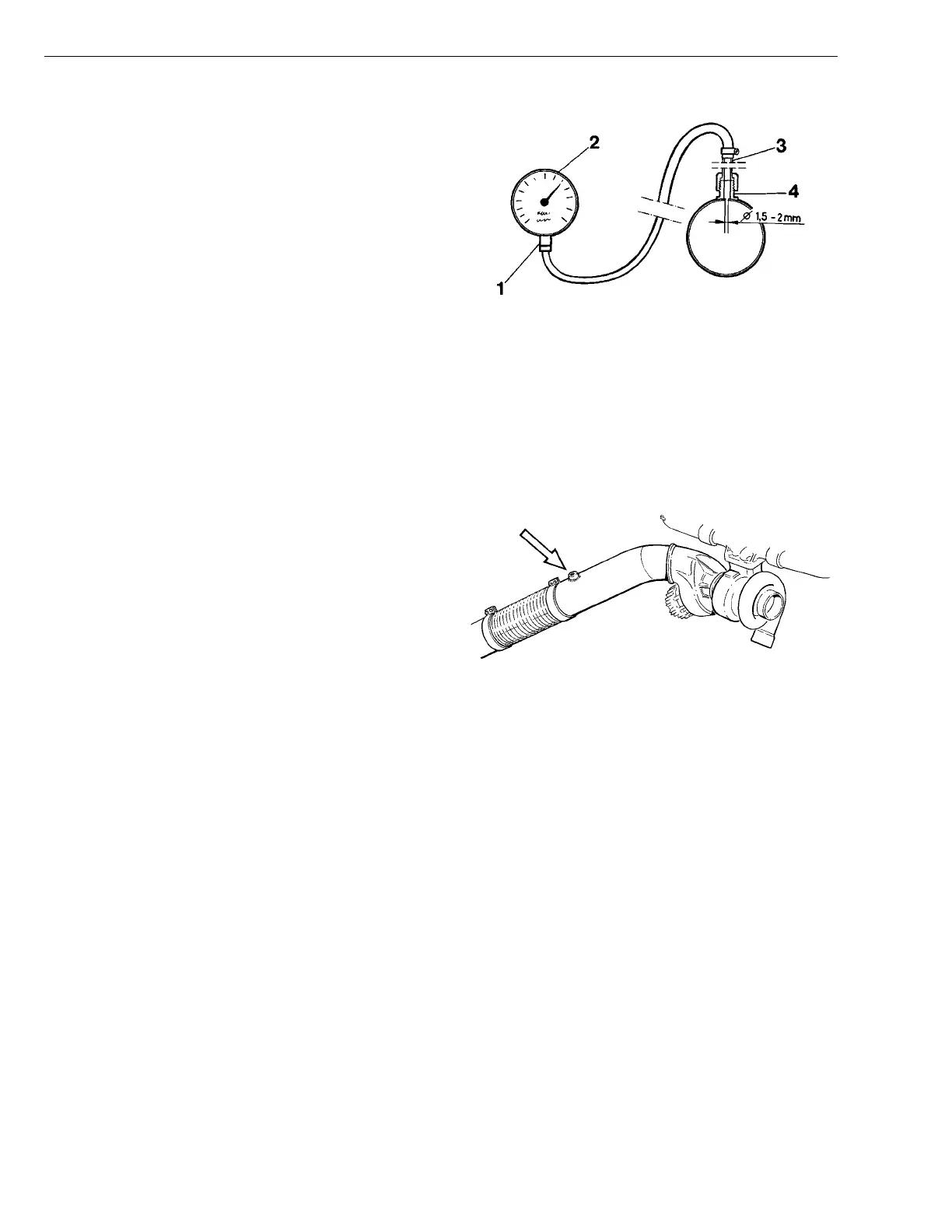

Pressure Testing Outlet Location

The pressure-testing fitting should be located on as

straight a section of the pipe as possible, two-thirds after

and one-third before a bend in the pipe.

The test fitting must not be located on an outer or inner

bend of the exhaust pipe.

T2006983

Outlet location

Backpressure Measuring Techniques

Using a chassis dynamometer is the best way to mea-

sure backpressure. If such equipment is not available,

the vehicle can be driven up a long hill. The accelerator

pedal must be kept fully floored with the vehicle acceler-

ating up the hill until the engine reaches specified rpm.

Note the highest backpressure reading and compare it

with specifications.

After the test, make sure to block off the union in the ex-

haust pipe with a plug, or in some other suitable manner.

42

Loading...

Loading...