32

Installation Manual

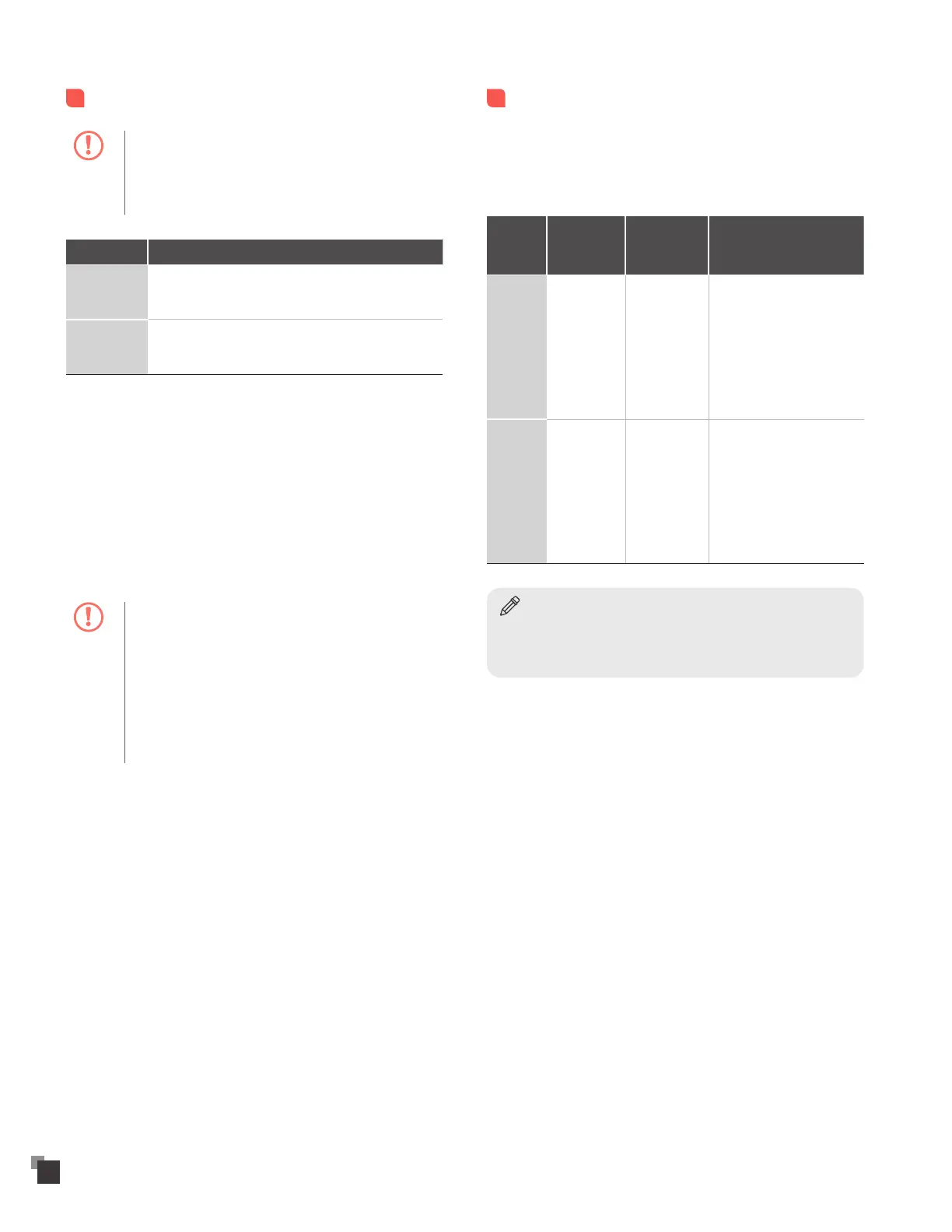

Vent Pipe Materials

Caution

Venting requirements differ in the US and Canada. Consult

the following chart or the most recent edition of ANSI Z223.1/

NFPA 54 or CAN/CGA B149.1, as well as all applicable local

codes and regulations when selecting vent pipe materials.

Do not use cellular core PVC (ASTM F891), cellular core CPVC,

Radel® (polyphenolsulfone) for the exhaust vent.

Locale Recommended Vent Materials

USA

• PVC Schedule 40 (solid core)

• CPVC Schedule 40 or 80 (solid core)

• Approved Polypropylene*

Canada*

• Type BH Special Gas Vent Class IIA (PVC)

• Type BH Special Gas Vent Class IIB (CPVC)

• Thpe BH Special Gas Vent Class IIC (Polypropylene)

* Approved polypropylene systems include:

Duravent Polypro (Single Wall): 2PPS-xxx (2 in), 3PPS-xxx (3 in)

Centrotherm Innoflue SW: ISxx02xx (2 in), ISxx03xx (3 in)

Centrotherm InnoFlue Flex: IFVL02XXX (2 in)

Refer to the manufacturer’s literature for detailed information.

* For installation in Canada, field-supplied plastic vent piping must comply with

CAN/CGA B149.1 (latest edition) and be certified to the Standard For Type

BH Gas Venting Systems, ULC-S636. Components of this listed system must

not be interchanged with other vent systems or unlisted pipes or fittings.

All plastic components and specified primers and glues of the certified

vent system must be from a single system manufacturer and must not be

intermixed with another system manufacturer’s parts. The supplied vent

connector and vent termination are certified as part of the water heater.

Caution

• This water heater has a built-in control to limit the exhaust

temperature to 149°F (65°C). As a result, the VST water

heater can be vented with Schedule 40 PVC.

• However, if you set the water heater at a temperature

above 150°F (66°C) for commercial use and you are also

incorporating either an external recirculation loop or a

combination heating system, the exhaust temperature can

exceed 149°F (65°C). In that case, you must use Schedule

40 or 80 CPVC or Approved Polypropylene in the USA

or Type BH Special Gas Vent Class IIB (CPCV) or Class IIC

(Polypropylene) that conforms to ULC-S636 in Canada.

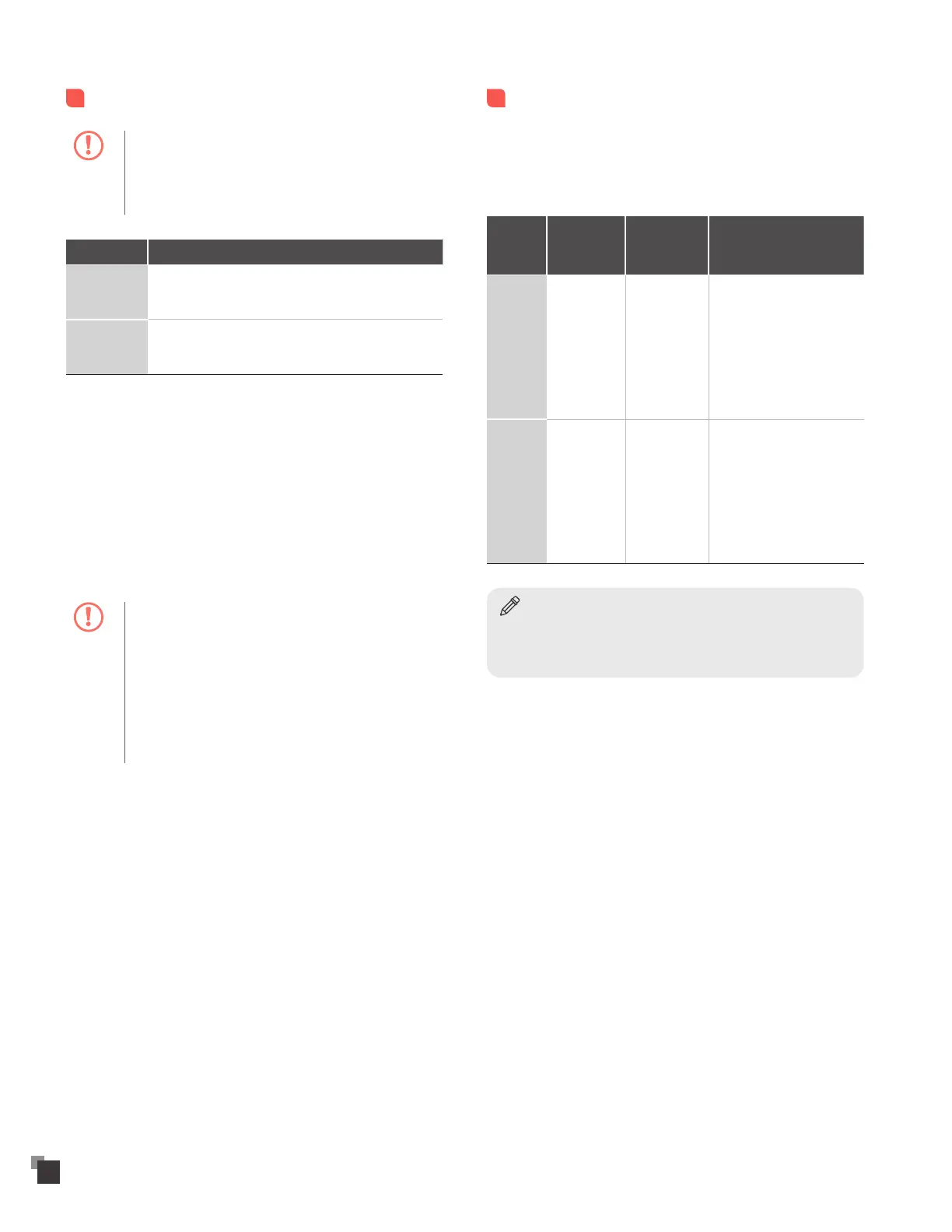

Vent Length

The maximum vent length when using 2" exhaust ducts is 60’. The

maximum vent length when using 3" vent ducts is 150’. The intake

duct length can be of equal length to the exhaust duct length. Both

maximum lengths are reduced by the number of elbows used, as

shown in the following table:

Vent

Size

Maximum

Length

Maximum

# of

Elbows

Equivalent Lengths

2" 60' (18 m) 6

Reduce the maximum vent

length accordingly for each

elbow used:

• Each 90° elbow equates

to 8 linear feet (2.4 m)

of vent

• Each 45° elbow equates

to 4 linear feet (1.2 m)

of vent

3" 150' (45 m) 8

Reduce the maximum vent

length accordingly for each

elbow used:

• Each 90° elbow equates

to 5 linear feet (1.5 m)

of vent

• Each 45° elbow equates

to 3 linear feet (0.9 m)

of vent

Notice

• The maximum length does not include any elbows.

• If using a concentric termination as shown on pages 34, count this as

8 linear feet (2.4 m) of vent.

Loading...

Loading...