18

VERSION 01/2018

ORDER NUMBER DOC 2316596

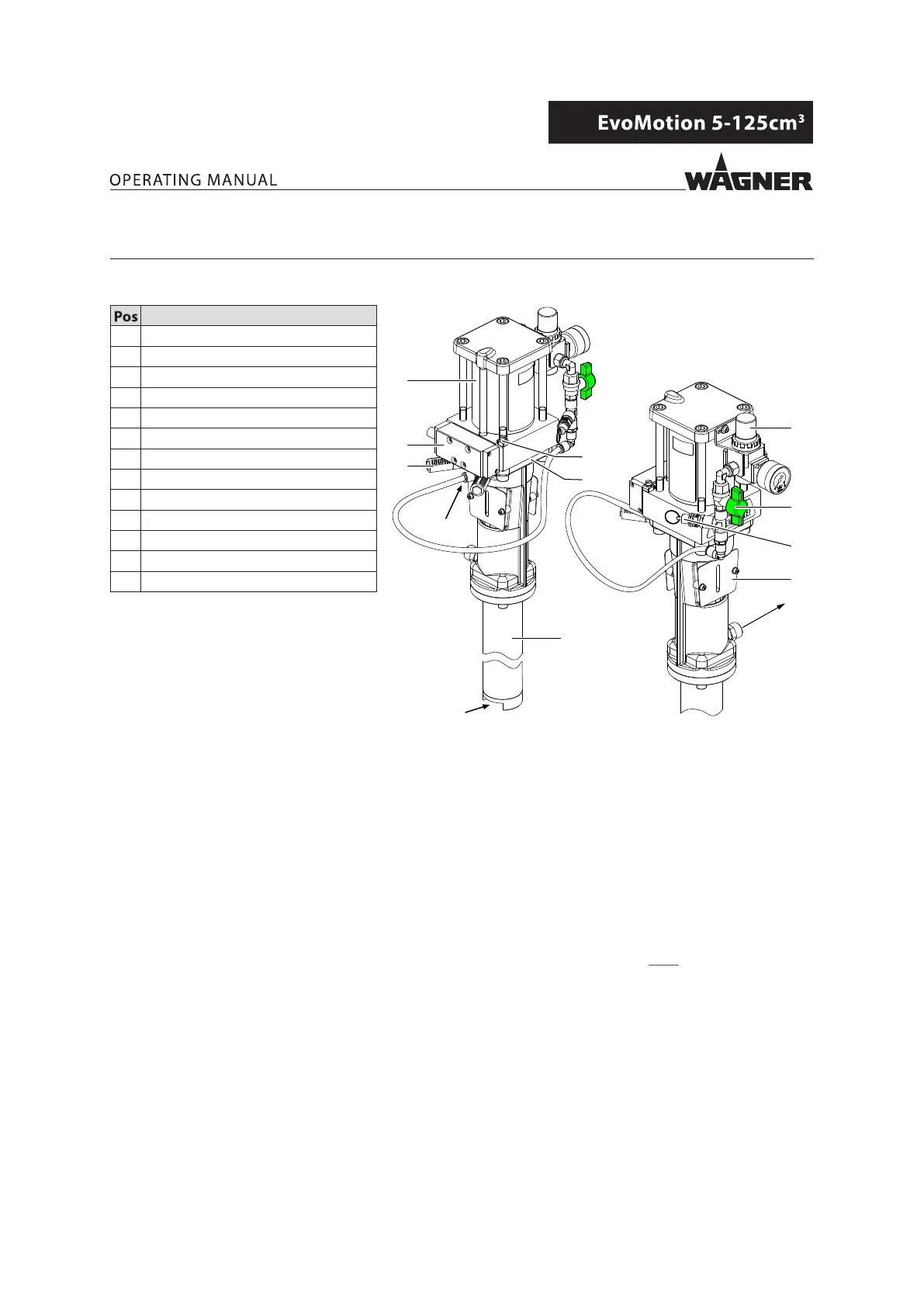

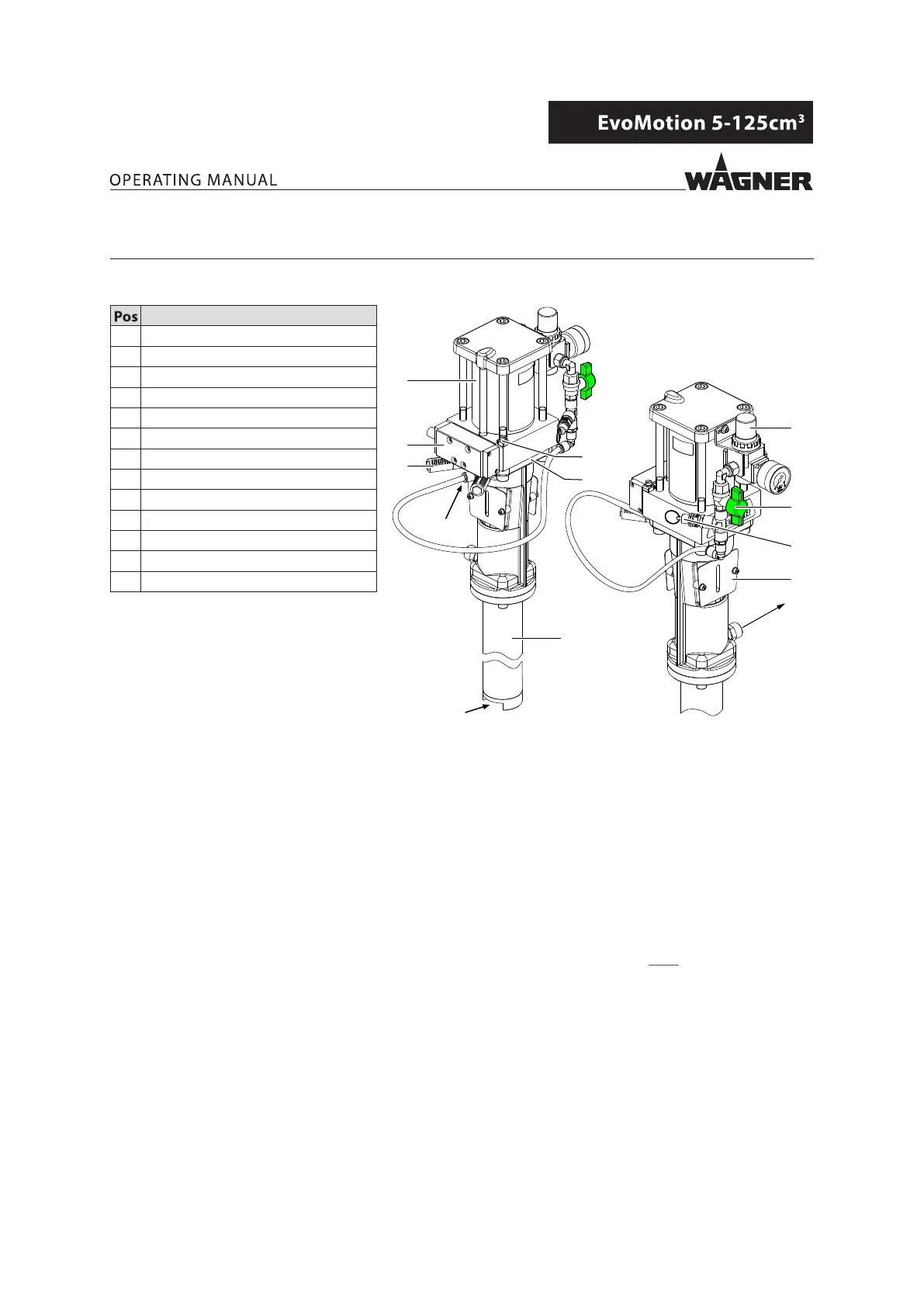

5 DESCRIPTION

5.1 COMPONENTS

Designation

1 Air motor

2 Reversing valve

3 Silencer

4 Air inlet

5 Product inlet

6 Grounding connection

7 Mounting ange

8 Fluid section

9 Air pressure regulator (option)

10 Ball valve (option)

11 Safety valve (option)

12 Spacer (separating uid tank)

13 Product outlet

B_06865

1

2

3

10

9

11

7

6

12

13

4

8

5

5.2 MODE OF OPERATION

The piston pump is driven with compressed air (4). This compressed air moves the air piston

up and down in the air motor (1) and it also moves the the associated pump piston up and

down in the uid section (8). At the end of each stroke, the compressed air ow is redirected

by a reversing valve (2). The working material is sucked up during the upwards stroke and

is continuously conveyed towards the product outlet (13) in both stroke directions.

5.2.1 AIR MOTOR

The air motor (1) with its pneumatic reversing valve (2) does not require pneumatic oil.

The compressed air can be fed to the motor via an air regulator (9, option) and a ball valve

(10 option). The air pressure regulator (9) is tted with a safety valve (11, see Chapter 5.3.1).

5.2.2 FLUID SECTION

The uid section is designed as a piston pump with ap valves. The pump piston runs in the

upper xed packings which are self-adjusting by means of a pressure spring. This results in

the packing having a long service life. There is a spacer (12) between the air motor and the

uid section. It serves to collect the separating agent.

Loading...

Loading...