32

VERSION 01/2018

ORDER NUMBER DOC 2316596

7.4 PRESSURE RELIEF/WORK INTERRUPTION

The pressure must always be relieved when:

− after the spraying tasks are nished,

− before servicing or repairing the spraying system,

− before carrying out cleaning tasks on the spraying system,

− Before moving the spraying system to another location.

− before something must be checked on the spraying system,

− before the nozzle or the lter is removed from the spray gun.

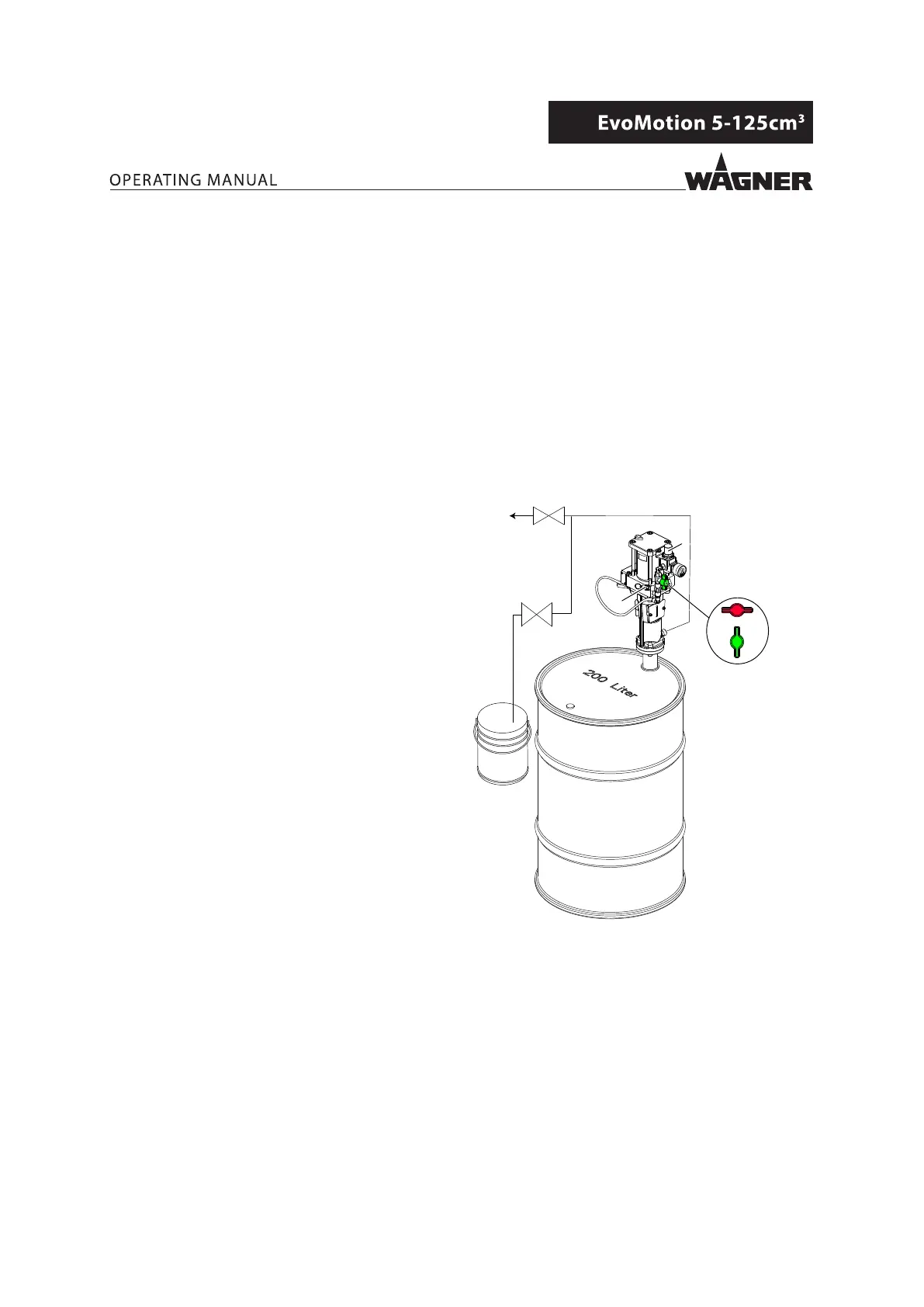

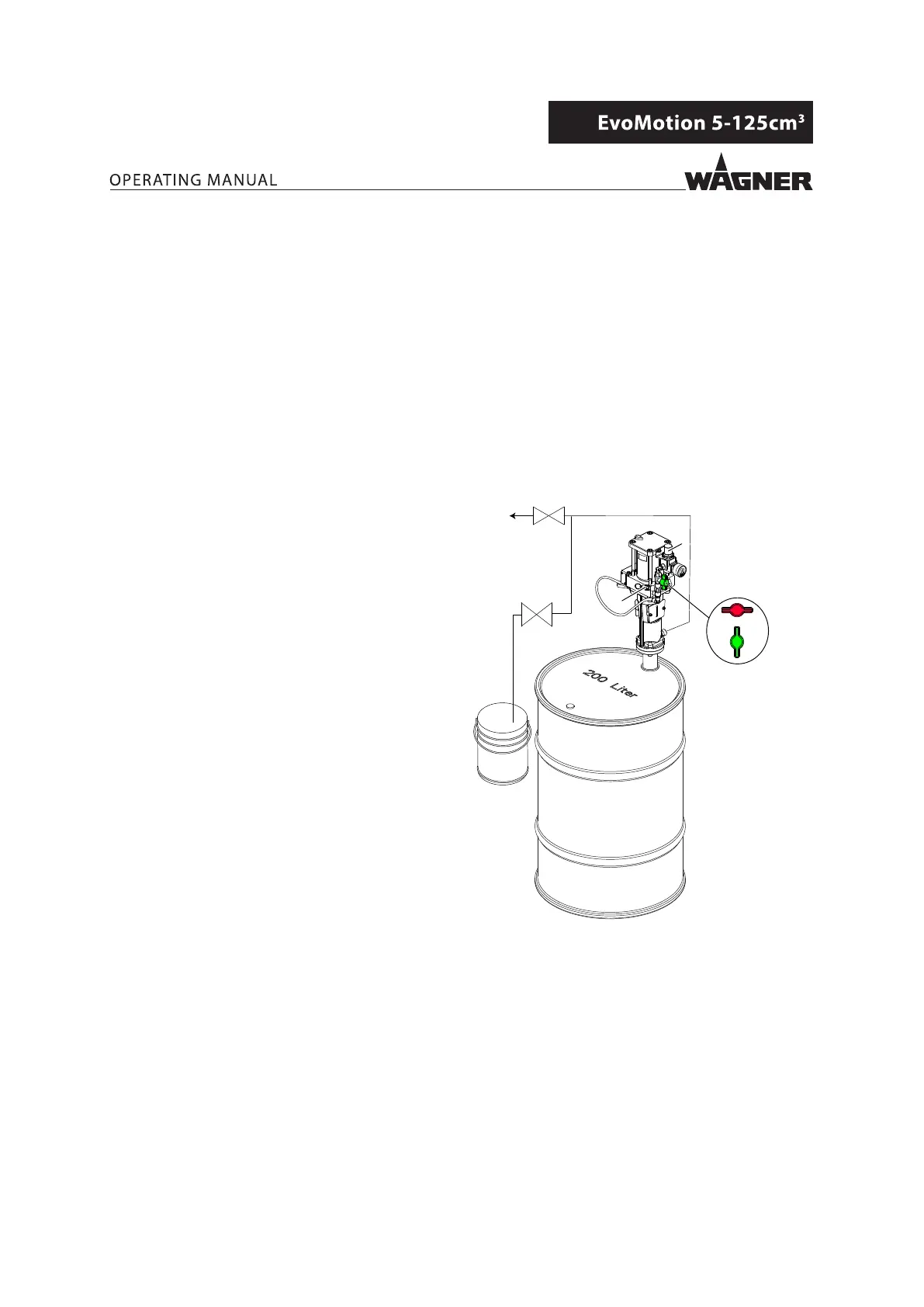

The components for pressure relief on a CE-compliant spraying system include:

− Air cock with pressure relief valve mounted between the compressed air source and

the pneumatic pump. In this case, the pressure relief valve is the safety valve (10).

− Outlet equipment (return valve) mounted between pump and spray gun.

Pressure relief procedure

4

2

1

B_06877

5

6

8

3

open

closed

1. Close the valve (4).

2. Completely close the ball valve (2).

3. Place grounded metal tank (5) for return

product under the return tube (3).

4. Slowly open the return valve (3).

5. When no further overpressure is detected,

close the return valve (3).

6. Pressure can still be present after the valve

(4). Relieve the pressure in the product line

downstream of valve (4) towards the front

if necessary. When doing so, observe the

superordinate operating manual.

Note:

Control air pressure is still present.

Pressure relief of the air

(in case of longer work interruptions)

1. Carry out pressure relief of the product (as

mentioned above).

2. Ensure that the ball valve (2) is closed.

3. Pull the ring on the safety valve (8) and hold

it until the pressure in the air motor has been

equalized.

Loading...

Loading...