40

VERSION 01/2018

ORDER NUMBER DOC 2316596

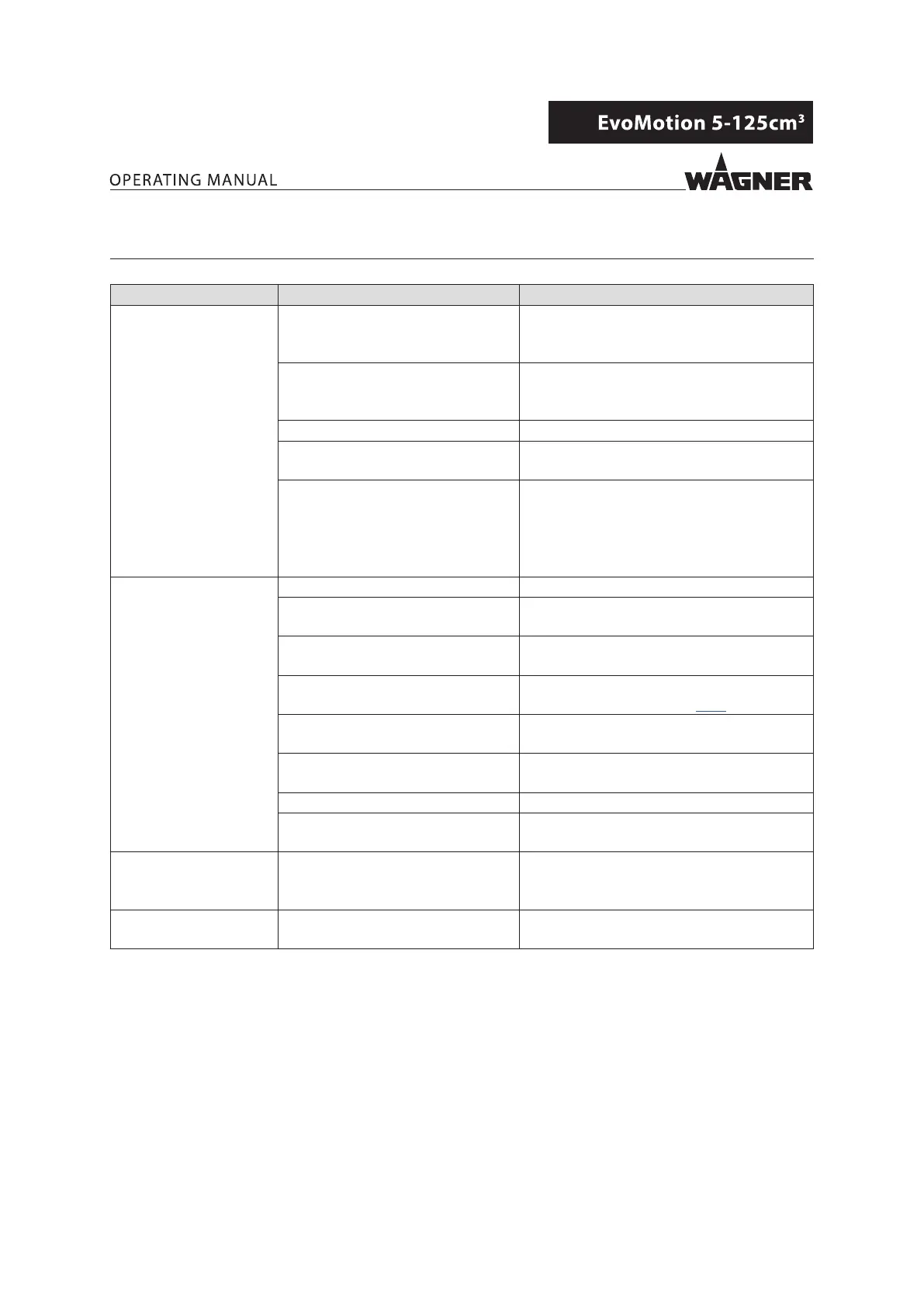

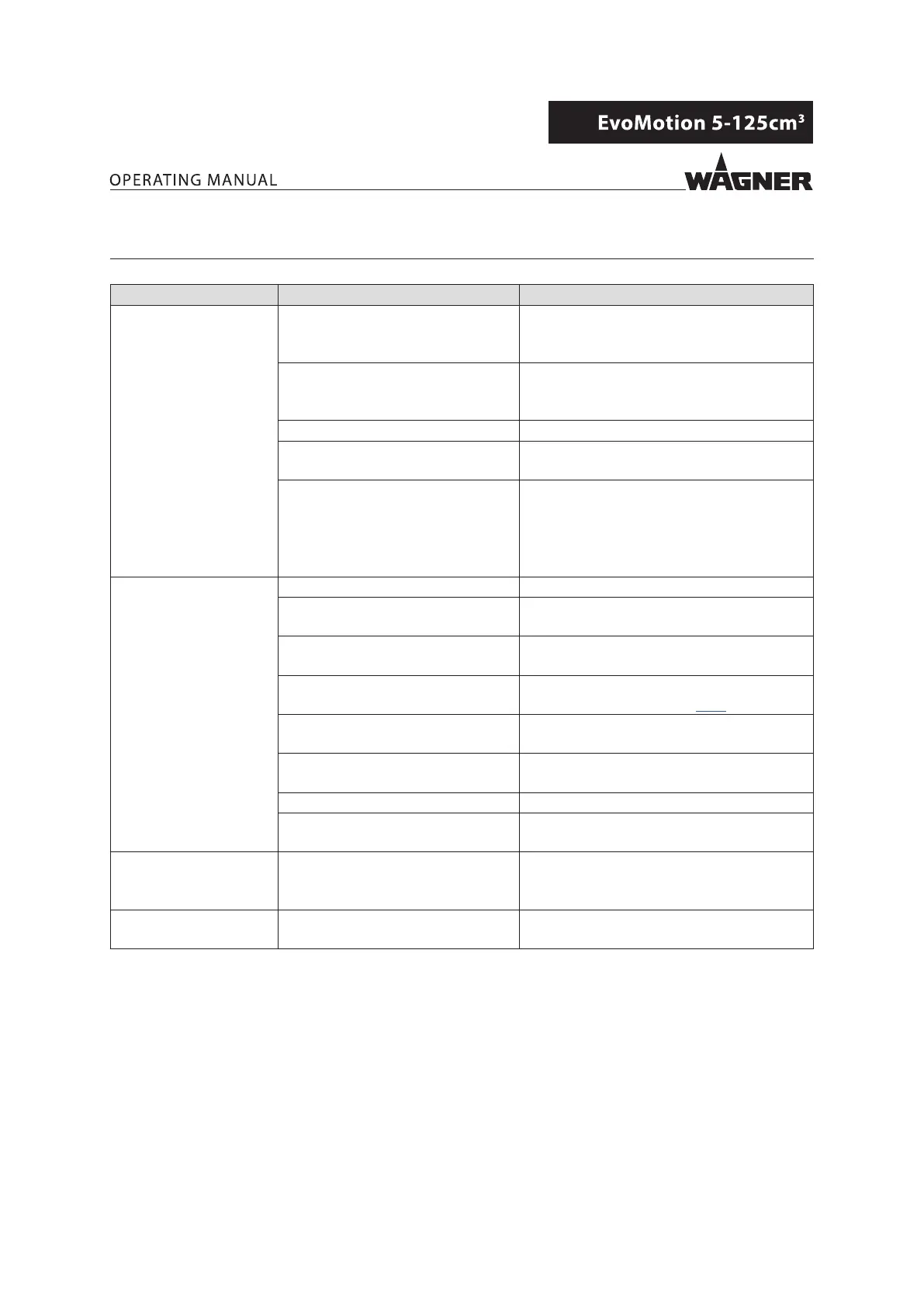

9 TROUBLESHOOTING AND RECTIFICATION

Problem Cause Remedy

The pump does not

work.

Air motor does not work or stops. Open and close ball valve on the pressure

regulator unit or briey disconnect

compressed air supply.

No pressure indication on the

pressure gauge (air pressure

regulator defective).

Disconnect compressed air supply briey or

repair or change air pressure regulator.

Insucient compressed air supply. Check compressed air supply.

Fluid section or high-pressure hose

are blocked.

Dismount and clean uid section, replace

high-pressure hose.

Sometimes, the pump stops at a

switching point.

Press the starter on the reversing valve and

restart the pump.

Clean the slide on the reversing valve

carefully and if necessary lubricate it lightly

with oil.

Irregular operation of

product pump; spray jet

with irregular pressure

(pulsation).

Viscosity is too high. Dilute the working material.

Valves are clogged. Clean product pump, if necessary leave it to

soak in cleaning agent.

Foreign body in suction valve. Dismantle suction valve housing, clean and

check valve seat.

Diameter of compressed air line too

small.

Assemble a larger incoming line

-> Technical Data, Chapter 5.5.3)

Valves, packings, or pistons are

worn out.

Replace the parts.

Control air lter or work air lter is

clogged.

Check and clean it if necessary.

Suction lter is clogged. Clean lter.

Ball in suction or piston valve is

stuck.

Clean with cleaning agent (if necessary vent

device).

The pump runs when

the discharge duct is

closed.

Packings, valves, or pistons are

worn out.

Replace the parts.

Air motor is iced up. There is a lot of condensation water

in the air supply.

Install a water separator.

If none of the causes of malfunction mentioned are present, the defect can be remedied by a WAGNER Service

Center.

Loading...

Loading...