36

VERSION 01/2018

ORDER NUMBER DOC 2316596

8.2.3 SAFETY CHECKS AND MAINTENANCE INTERVALS

Every day

Check grounding: see Chapter 6.6.

Check hoses, tubes and couplings: see Chapter 8.2.3.2

Check the level of separating agent in the separating agent tank and top up, if

necessary, in accordance with Chapter 8.2.3.1.

For each decommissioning, the process according to Chapter 8.1.2 must be followed.

If the pump has to be emptied for maintenance work, proceed according to Chapter

7.5 and Chapter 8.2.4.

Weekly

Check system for damage.

Check that the safety xtures function properly (see Chapter 5.3).

Yearly or as required

In accordance with DGUV regulation 100-500 Chapter 2.29 and 2.36:

– The liquid ejection devices should be checked by an expert (e.g., WAGNER

service technician) for their safe working conditions as required and at least

every 12 months.

– For shut down devices, the examination can be suspended until the next start-

up.

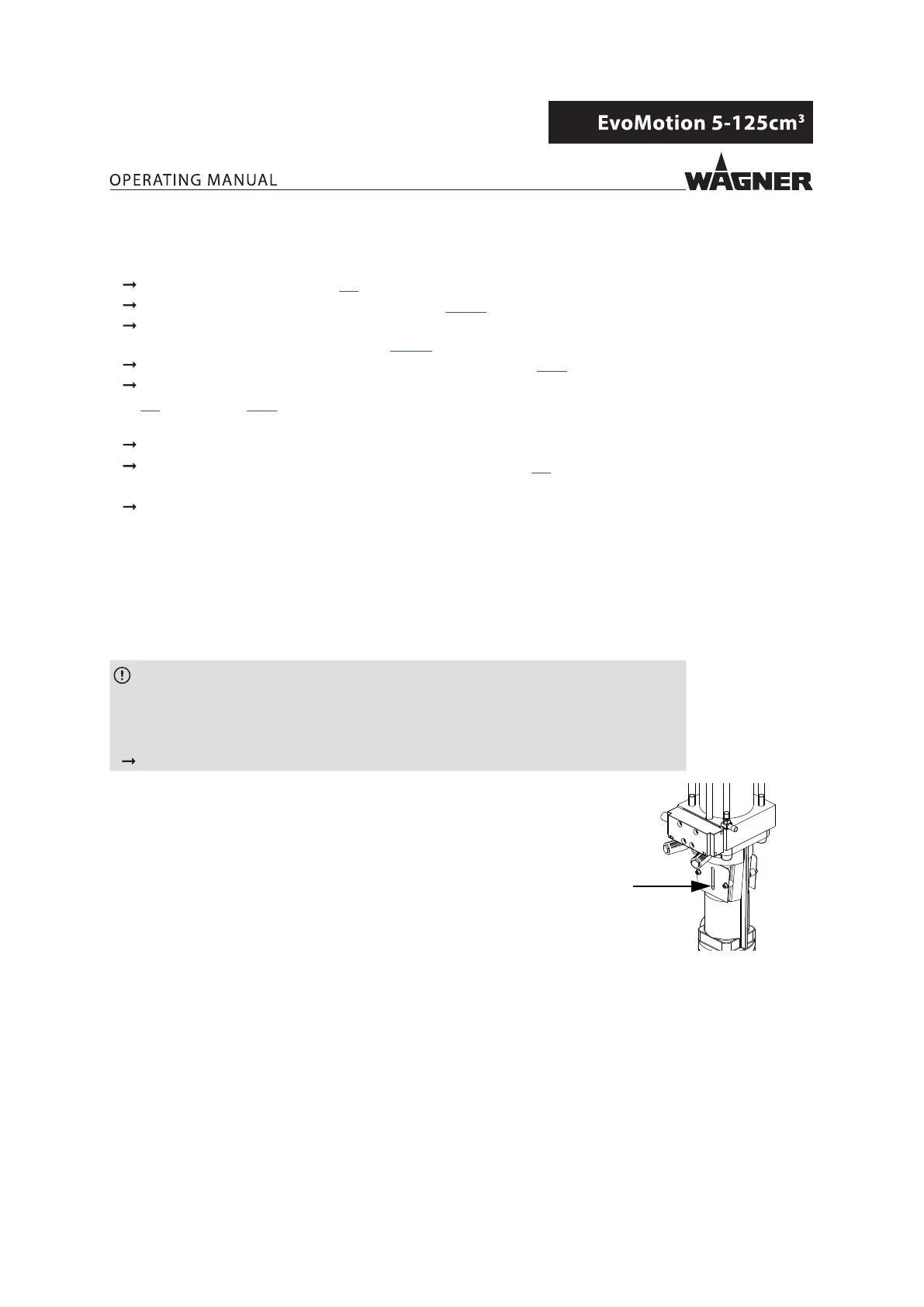

8.2.3.1 FILLING WITH SEPARATING AGENT

NOTICE

Piston pump dry run!

High wear/damage to the packings.

Paint or solvent can escape if the seals are dry.

Ensure that the separating agent tank is lled with sucient separating agent.

To prevent potential transportation issues, the separating uid chamber of the

pump is not lled at the factory.

Pour the supplied separating agent into the intended opening.

C_00107

Separating agent: Order no. 9992504

Inclination angle of the pump

Maximum permissible tilt of the pump for moving, transporting, etc. after lling

separating agent is±30°.

The pump must be vertical during operation.

Loading...

Loading...