34

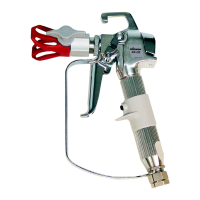

GM 5000EA

B_03267

OPERATING MANUAL

EDITION 07/2014

ORDER NUMBER DOC

2344499

Spraying direction

By turning the lateral adjusting screw of the gun, the outlet cross-section can be

adjusted on the product valve. By reducing this cross-section under the same pressure

settings you can create a further re nement of the atomization, i.e. turning the adjustment

screw upwards.

Rotate upward

Stop forward smaller

cross-section

Rotate downward

Stop backward greater

cross-section

6.6.2 PRESSURE SETTINGS FOR FLAT JET NOZZLES

Pressure settings Air cap 0.4-0.8 Air cap 1.0-1.4 Air cap 1.6-2.0

Product pressure

0.5 bar to 1.0 bar 1.0 bar to 2.0 bar 1.0 bar to 3.0 bar

Atomizing air pressure 1.0 bar to 2.5 bar 1.5 bar to 2.5 bar 1.5 bar to 3.0 bar

Note:

The table contains default values. Depending on the product, conditions and the desired

result di erent values are possible or necessary.

By turning the lateral adjusting screw

of the gun, the outlet cross-section can be

adjusted on the product valve. By reducing this cross-section under the same pressure

settings you can create a further re nement of the atomization, i.e. turning the adjustment

screw upwards.

Note:

With this setting the spray pattern is reduced.

There are 8 at jet nozzle sizes from 0.6 up to 2.0 available. There are 3 air cap types. Each air

cap can be used in combination with 2 or 3 nozzles sizes. Only matching nozzle components

may be used. During the calibration of the product pressure

and the atomizing air

pressure

the air control lever shown in gure B_03266 must be in a central position.

These presettings are based on a lacquer viscosity of 22 DIN 4 sec.

Loading...

Loading...