47

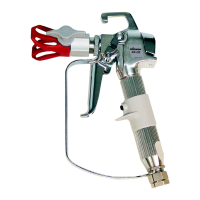

GM 5000EA

OPERATING MANUAL

EDITION 07/2014

ORDER NUMBER DOC

2344499

8.2 MAINTENANCE

Maintenance work should be undertaken regularly and carefully by quali ed and trained

sta .

The following hazards may arise during maintenance work:

Health hazard from inhaling solvent vapors

Use of unsuitable tools and aids

Once the maintenance work is complete, the device must be checked by a quali ed person

to ensure a reliable condition.

8.2.1 MAINTENANCE STAFF

8.2.2 SAFETY INSTRUCTIONS

Incorrect maintenance/repair!

Danger to life and equipment damage.

Repair or replacement of devices or parts of devices are only

allowed to be performed outside the hazard area by quali ed

personnel.

DANGER

Check hoses, pipes, and couplings every day and replace if necessary.

In accordance with the guideline for liquid ejection devices (ZH1/406 and BGR500

Part2 Chapter 2.36):

- The liquid ejection devices should be checked by an expert (e.g. Wagner service

technician) for their safe working conditions as required and at least every 12

months.

- If devices have been decommissioned, the examination can be suspended until the

next start-up.

Loading...

Loading...