Super Finish 21 • 23 31

gg

3.4 Technical data

Super Finish Super Finish

21 23

Voltage : 230 Volt~, 50 Hz

220 Volt~,60 Hz

110 Volt~, 50 Hz

Fuse protection : 16 A slow-blow

Unit connection line : 6 m long, 3 x 1.5 mm

2

Socket on unit : 230 Volt ~, 50 Hz

220 Volt~, 60 Hz

110 Volt~, 50 Hz

Max. connection : 1000 Watt

400 Watt (110 Volt~, 50 Hz)

Type of protection : IP 44

Capacity : 0.96 kW 1.3 kW

Max. operating pressure : 250 bar (25 MPa)

Max. volume flow : 2.0 l/min 2.4 l/min

3.0 l/min

(220 Volt~, 60 Hz)

Volume flow at 120 bar

(12 MPa) with water : 1.7 l/min 2 l/min

2.6 l/min

(220 Volt~, 60 Hz)

Max. size of tip : 0.021 inch 0.023 inch

– 0.53 mm – 0.58 mm

0.027 inch

– 0.69 mm

(220 Volt~, 60 Hz)

Max. temperature of

the coating material : 43°C

Max. viscosity : 25.000 mPa·s

Net weight : 26 kg 31 kg

Hydraulic filling quantity : 0.9 litre, ESSO NUTO H 22

Max. acoustic pressure level : 74 dB (A)*

* Place of measuring: 1 m in distance from the unit and 1.6 m

above the floor, 120 bar (12 MPa) operating

pressure, reverberant floor

3.5 Transport

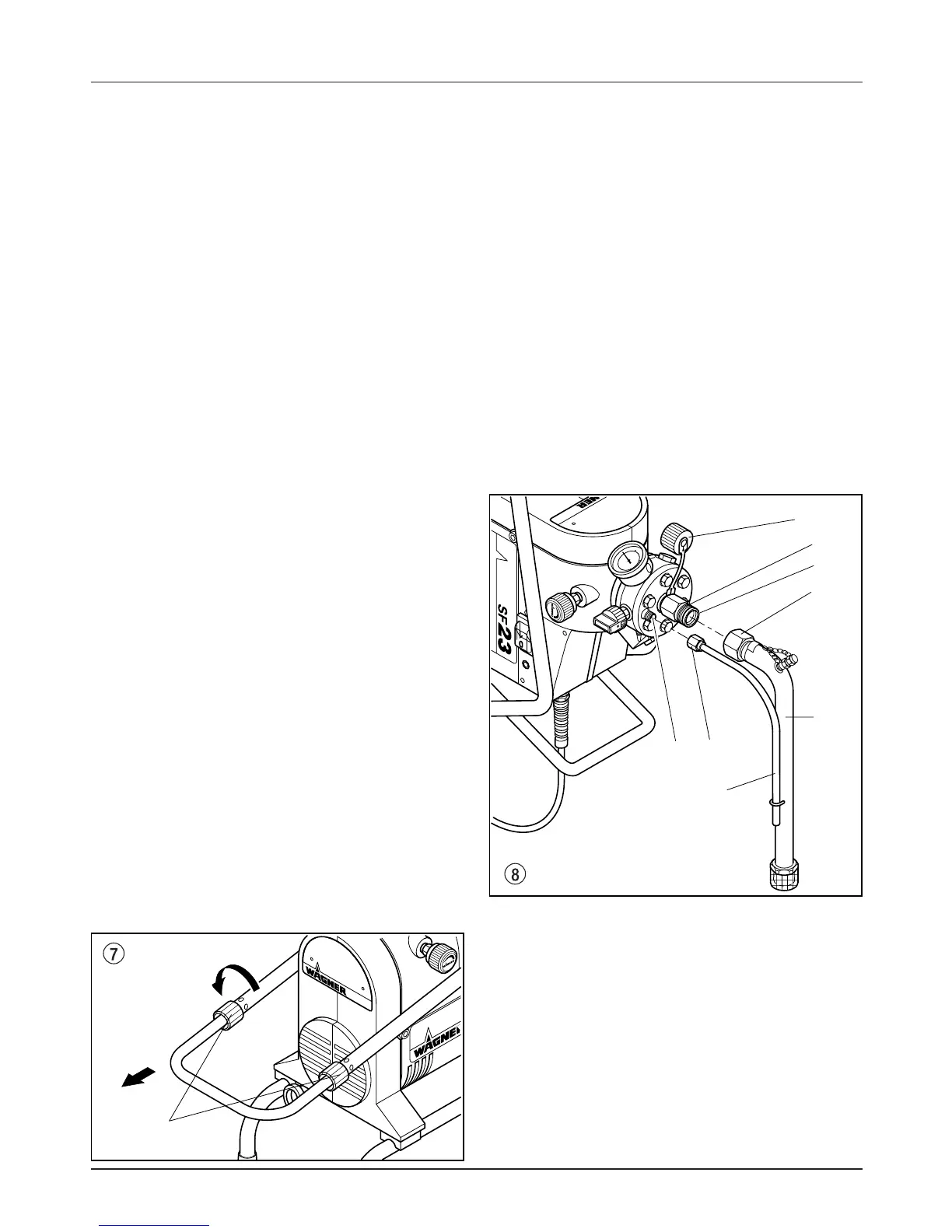

Super Finish 23

Push or pull unit.

Loosen terminal sleeves (fig. 7, item 1) on the shaft (L

open). Extract shaft to the desired length.

Tighten terminal sleeves again by hand (R closed).

Description of unit Starting operation

Transport in vehicle

Super Finish 23

Unroll high-pressure hose and lay it over the shaft.

Super Finish 21 and 23

Secure the unit by means of suitable fastening.

4. Starting operation

4.1 Unit with suction system

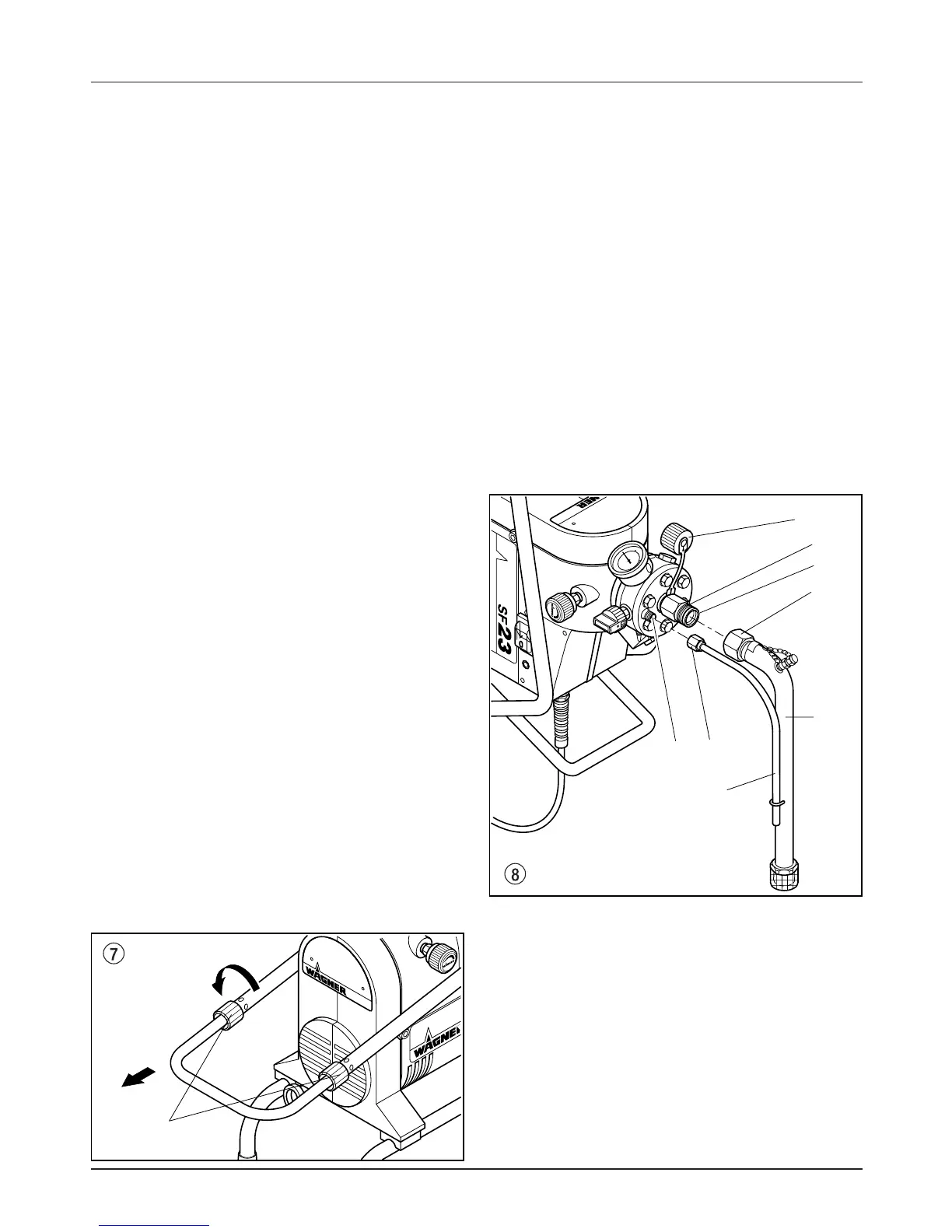

1. Screw off dust protection cap (fig. 8, item 1).

2. Pay attention to clean sealing areas on the

connections.

Pay attention to the fact that the red inlet (2) is in-

serted into the coating material inlet.

3. Screw and tighten the union nut (3) on the suction

pipe (4) onto the coating material inlet (5) with the

accompanying spanner 41 mm.

4. Screw the union nut (6) on the return pipe (7) onto

the connection (8).

4.2 Unit with upper hopper (5 litres)

1. Screw off dust protection cap (fig. 9, item 1).

2. Pay attention to clean sealing areas on the

connections.

Pay attention to the fact that the red inlet (2) is in-

serted into the coating material inlet.

3. Screw the upper hopper (3) onto the coating ma-

terial inlet (4).

4. Hang the return pipe (5) into the upper hopper.

5. Screw the union nut (6) on the return pipe (5) onto

the connection (7).

Loading...

Loading...