Maintenance Instructions CLEANING

63

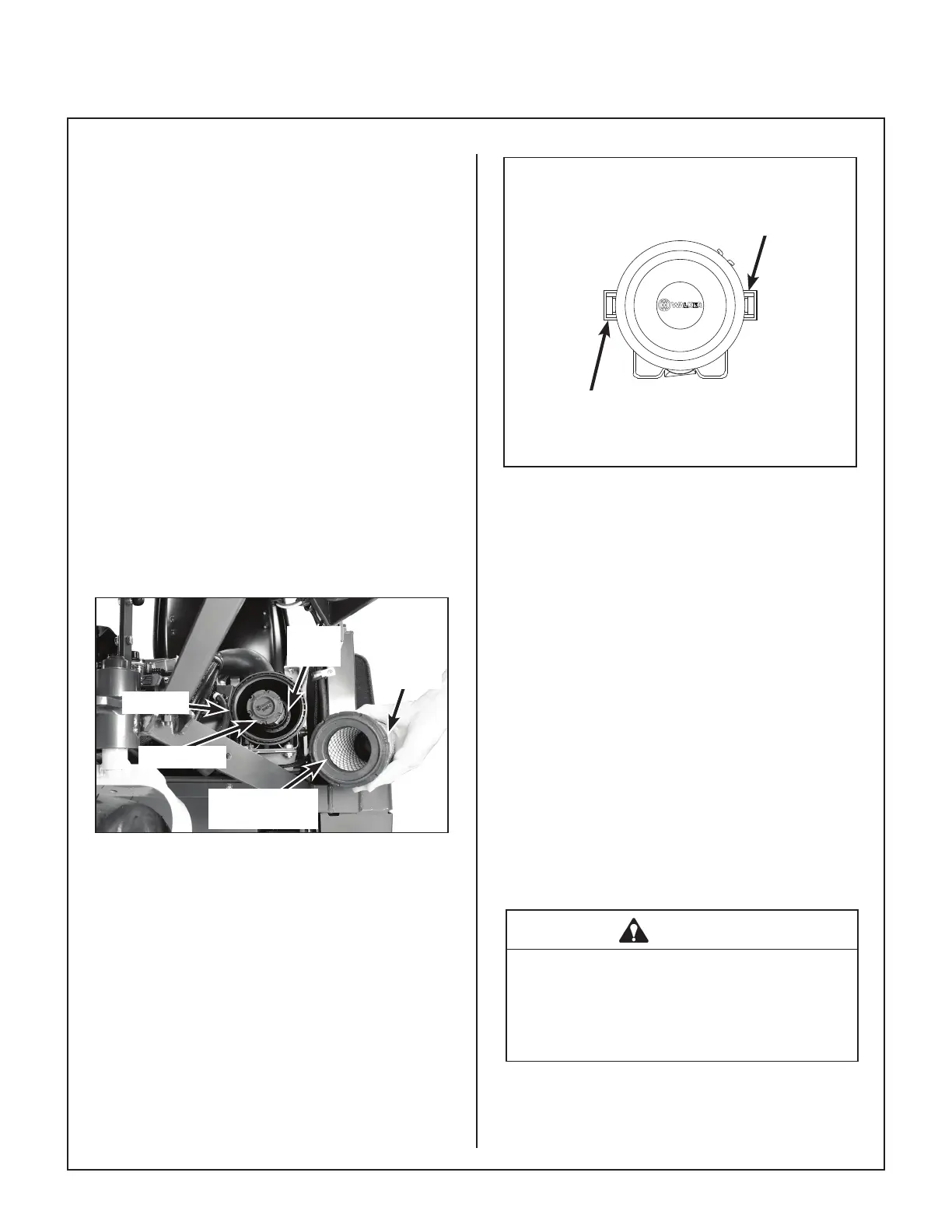

7. After removing the safety lter, use a clean,

damp cloth and wipe the interior of the air clean-

er canister clean. Use special care to clean

both the inside and outside surfaces of the

outlet tube.

IMPORTANT: Any dust left on the inside of the

outlet tube will go into the engine and cause

wear.

8. Check the outside surface of the outlet tube for

smoothness and cleanness (this is the sealing

surface).

9. Insert and seat the safety lter and primary lter

el ement carefully into the canister, applying

pres sure at the outer rim of the lter; not at the

exible center. Make sure the lter element is

completely in place before installing the cover.

NOTE: DO NOT use petroleum based lubri-

cants on the sealing surfaces of the lter; use

tal cum powder or dry silicone lubricants if re-

quired for lter installation.

Radial Sealing

Surface

Canister

Outlet

Tube

Safety Filter

Primary

Filter

Element

Air Filter Element Replacement

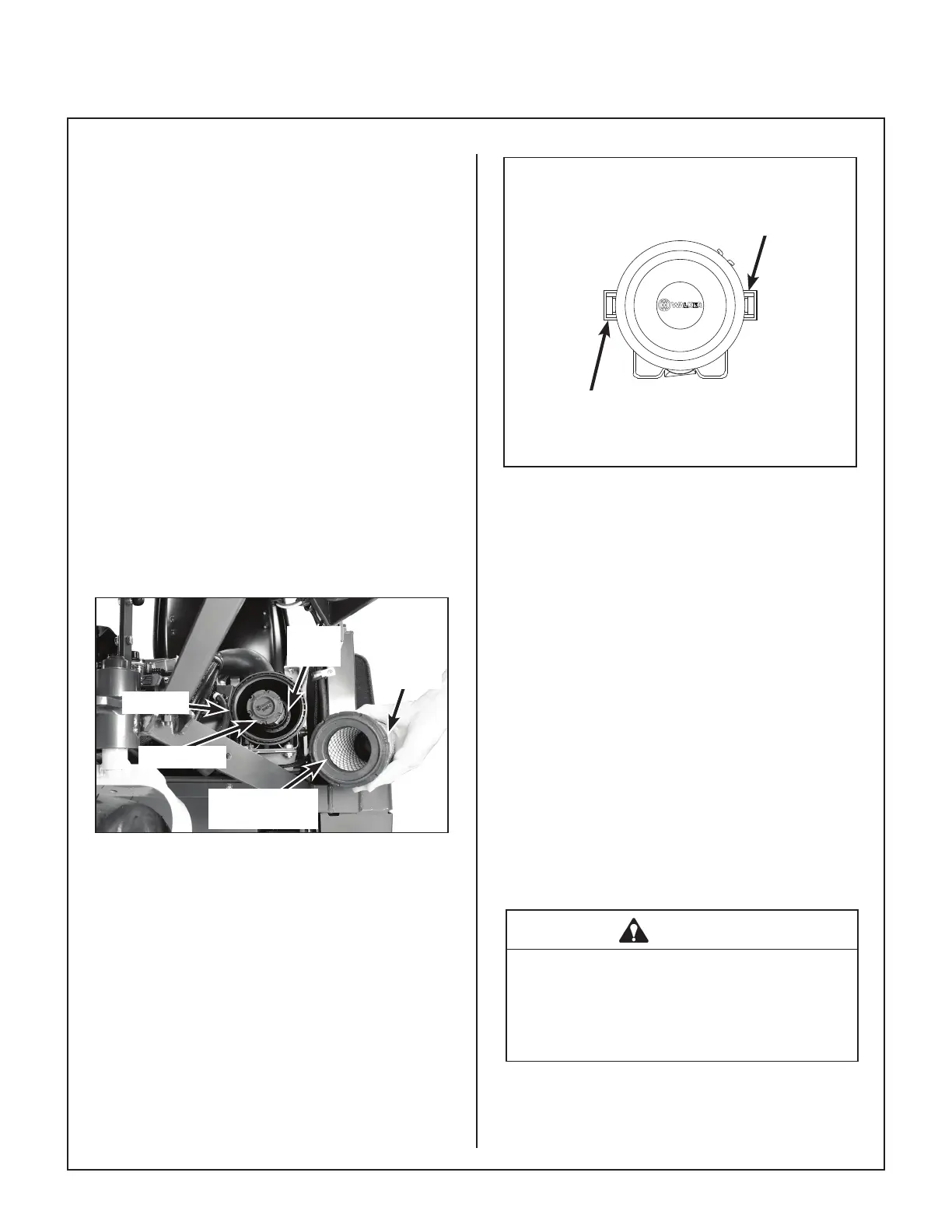

10. Install the Enginaire™ air cleaner cover. Latch

the two (2) cover latches.

Cover

Latch

Cover

Latch

Proper Orientation of Air Cleaner Cover

11. Check the air intake hose for cuts, nicks, cracks,

etc., and the hose clamps for tightness.

12. Reset the air lter restriction gauge (press but-

ton on the end of the indicator).

Engine Cooling System

Cooling Air Intake Screen

To prevent engine overheating and possible engine

damage, clean grass clippings, cha, and dirt from

the rotating engine cooling air intake screen after

every 8 hours of operation. In certain mowing

conditions (dry grass, leaves, tree “cotton”, etc.), it

may be nec essary to check and clean the screen

several times each day to prevent engine overheat-

ing. Also, visually check inside cylinder head

shroud and between cylinder head ns for material

packed in this area which would prevent cooling

airow; remove shroud and clean as required.

CAUTION

Operating the engine with a blocked air

intake screen, dirty or plugged cooling

ns, and/or cooling shrouds removed will

cause engine damage from overheating.

Loading...

Loading...