Maintenance Instructions CLEANING

57

Inspect the paper element after every 100 hours of

service and replace the element and safety lter ev-

ery 400 hours (or when dirty or damaged). More

frequent replacement may be required when operat-

ing in extremely dusty con ditions. Ser vice the air

cleaner as follows:

1. Lift Mono Latch Twist Lock

TM

and twist the Opti-

Air

TM

cover to the left into the “open” position to

remove the air cleaner cover. Wash the cover

and dust ejection valve. Check that these com-

ponents are in good condition. The dust ejec-

tion valve is subject to wear and deterioration

and should be inspected carefully and replaced

every 2 years or when worn or damaged. The

lips of the valve should close and t togeth er;

any cracks, deformation, or wear in the valve is

cause for replacement.

2. Remove the lter element by pulling it out of the

canister. There will be some initial resistance

as the lter seal breaks loose and slides o of

the outlet tube. Gently move the end of the

lter up and down and side to side or twist to

loosen the seal. Use gentle action to minimize

the amount of dust dislodged as the lter is re-

moved.

3. Clean the lter element by gently tapping on a

at, hard surface. If excessive restriction still

exists after cleaning the element, if should be

replaced.

NOTE: Use care when cleaning the lter ele-

ment. The lter element and/or seal surface

may be damaged by tapping too hard or hitting

on an uneven surface or sharp edge. Washing

the paper element in water or cleaning solution

is not recommended. Do not try to clean the

element with compressed air. Do not oil the

paper element. Remember, replacing a lter is

less expensive than replacing a dusted engine.

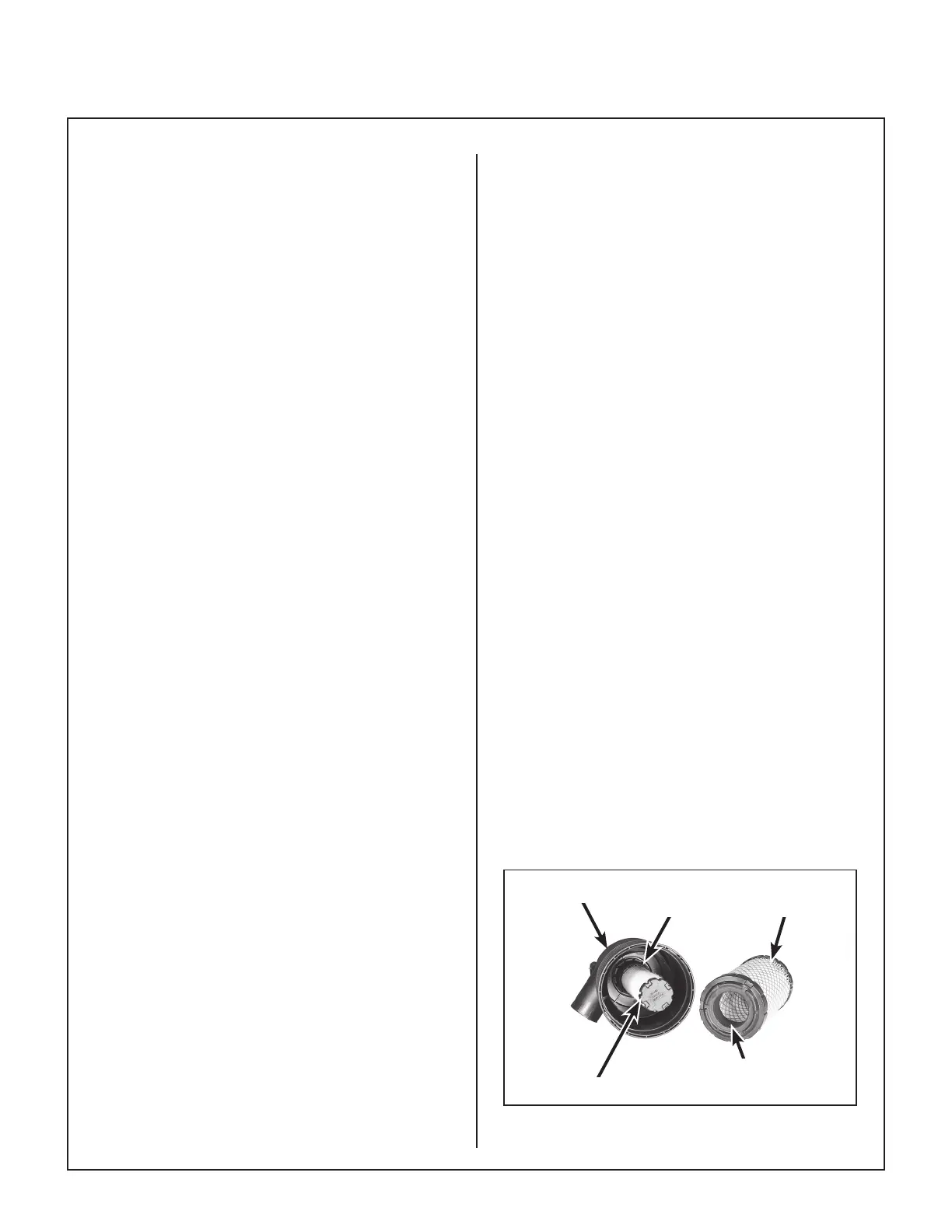

4. Use a bright light inside the lter element to in-

spect for damage. Check the element very

carefully for pin holes or other damage that

will allow dirt to leak through the paper media.

Replace lter element if dirty or damaged.

5. Check the condition and resilience of the radial

sealing surface (inside of the open end) of the

lter. Replace the lter if any cracks, tears, or

other damage to the sealing surface are noted.

6. Without removing, visually inspect the condition

of the safety lter for damage or holes. The

safety lter should only be removed for replace-

ment every 400 hours (or when dirty or dam-

aged).

IMPORTANT: Prior to removing the safety lter,

make sure the inside surface of the air cleaner

canister is clean. This will minimize the risk of

dirt entering the outlet tube which can cause pre-

mature engine wear.

7. After removing the safety lter, use a clean,

damp cloth and wipe the interior of the air clean-

er canister clean. Use special care to clean

both the inside and outside surfaces of the

outlet tube.

IMPORTANT: Any dust left on the inside of the

outlet tube will go into the engine and cause

wear.

8. Check the outside surface of the outlet tube for

smoothness and cleanness (this is the sealing

surface).

9. Insert and seat the safety lter and primary lter

element carefully into the canister, applying

pressure at the outer rim of the lter; not at the

exible center. Make sure the lter element is

completely in place before installing the cover.

IMPORTANT: DO NOT use the cover to force

the lter into the canister–the cover should t

on with no extra force.

NOTE: DO NOT use petroleum based lubri-

cants on the sealing surfaces of the lter; use

tal cum powder or dry silicone lubricants if re-

quired for lter installation.

Canister

Safety Filter

Primary

Filter Element

Radial Sealing

Surface

Outlet

Tube

Air Filter Element Replacement

Loading...

Loading...