Maintenance Instructions

47

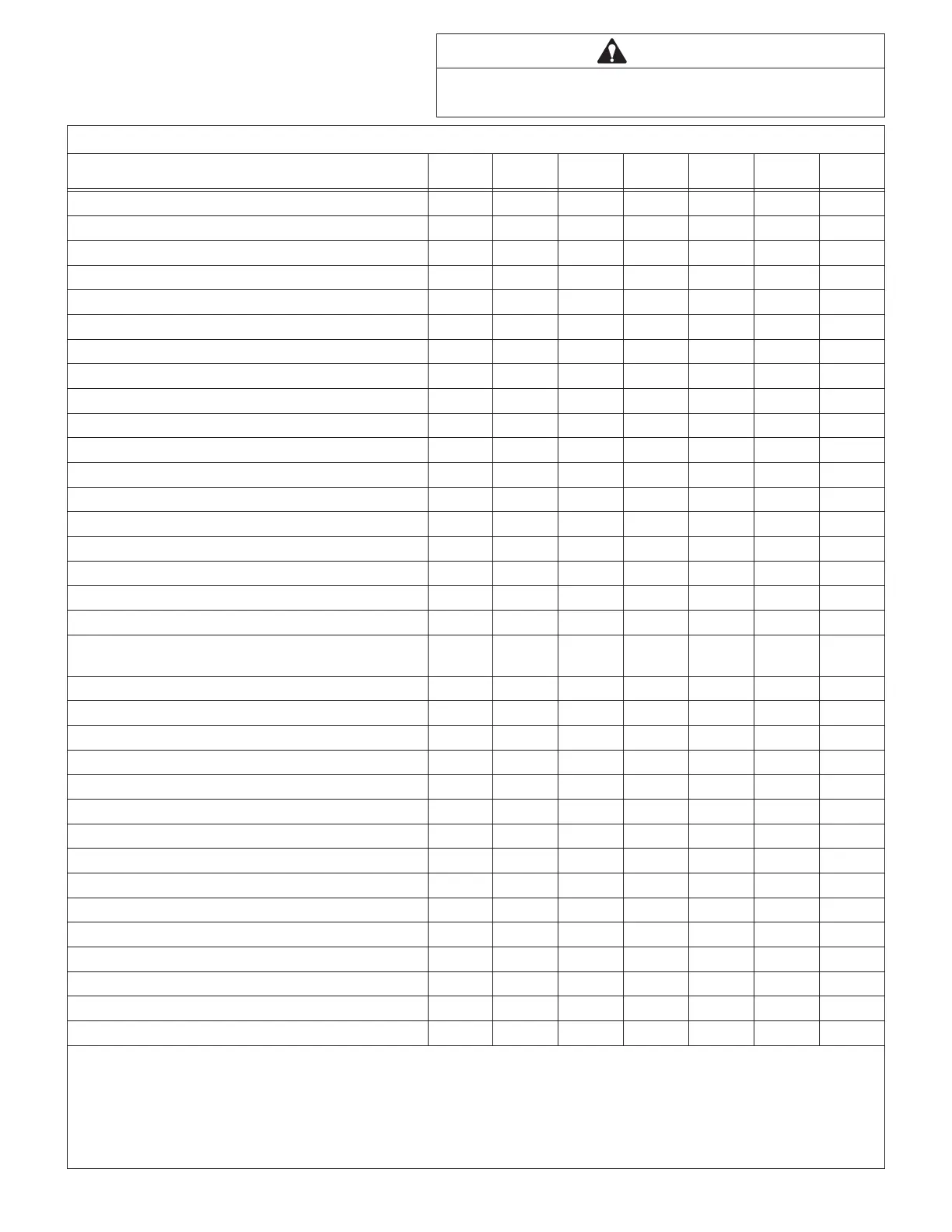

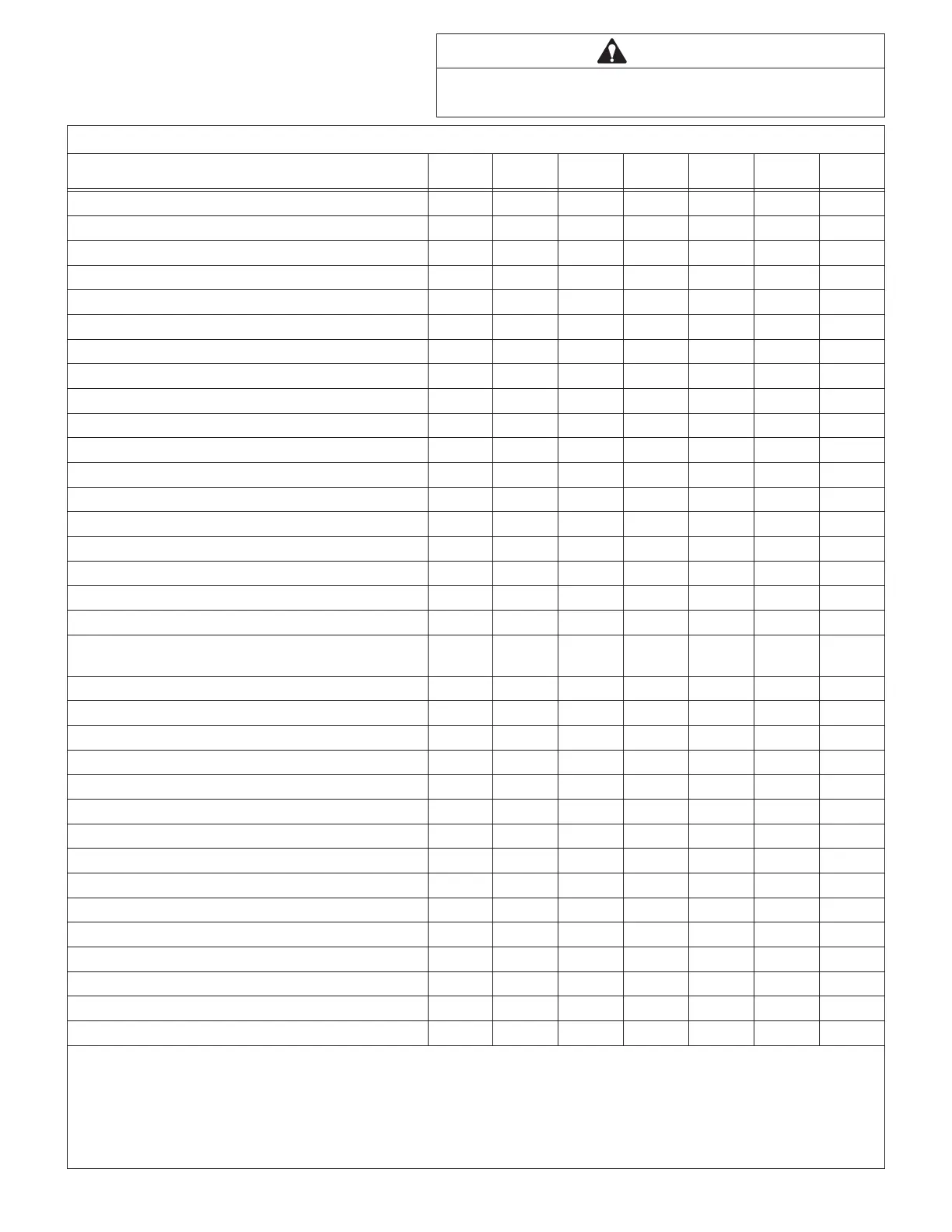

MAINTENANCE SCHEDULE CHART - RECOMMENDED SERVICE INTERVALS - MODEL S18

Service Item

Daily

25

Hours

100

Hours

400

Hours

Yearly

Every

2 Years

Ref.

Page

Check Engine Crankcase Oil Level x 49

Check/Clean Engine Air Cooling System* x 58

Clean Grass Buildup Under Deck x 60

Clean GHS Exhaust Screen* x 60

Clean GHS Blower* x 61

Service Mower Blades x 63

Check Security of Air Filtration Components x 62

Lubricate Grease Fittings and Oil Points* x 51

Check Battery Electrolyte Level x 62

Check Transaxle Fluid x 54

Check Tire Pressure x 63

Check Drive Belts (Engine, PTO, Ground Drive) x 64

Check Deck Gearbox Oil Seals x 65

Check Safety Switch System x 66

Change Engine Crankcase Oil and Oil Filter** x 50

Check Air Filter Element* x 57

Clean Transaxle Housing x 61

Check/Regap Spark Plugs x 65

Check Security of Drive Tire

Mounting Nuts (75 to 85

lb·ft)

x 63

Check Blade Brake Action x 65

Check/Adjust Blade Clutch x 78

Change Transaxle Oil and Filter

Δ

x 55

Replace Air Filter Element and Safety Filter*** x 57

Replace Fuel Filter x 71

Clean Engine Cooling Fins x 59

Check Fuel Lines and Clamps x 65

Service Battery x 62

Check/Adjust Vertical Position of Grass-Pak

®

Switch x 81

Check/Adjust FSC Friction Lock x 66

Check Transmission Control Settings x 65

Check PTO U-Joints for Wear/Looseness x 66

Replace Fuel Lines and Clamps x 65

Replace Dust Ejection Valve*** x 57

Replace Ignition Wires x 65

*

More often in extremely dusty or dirty conditions (refer to notes about air cleaner element in

IMPORTANT TIPS FOR CARE OF THE BRIGGS & STRATTON ENGINE)

**

Change engine oil after rst 8 hours of operation of a new engine (break-in period)

***

Air cleaner is remote mounted Cummins/Fleetguard

OptiAir™ unit, replace lter(s) every 400 hours and

dust ejection valve every 2 years or when worn or damaged

Δ Change transaxle oil after the initial break-in period of 75-100 hours operation

CAUTION

Maintenance procedures requiring special training or

tools should be performed by a trained technician.

Loading...

Loading...