3. If a seal doesn’t form within about 5-10

min, it probably will not. Take a new

pipette and start again.

4. Never attempt to clean and re-use a used

pipette. It will never make a seal.

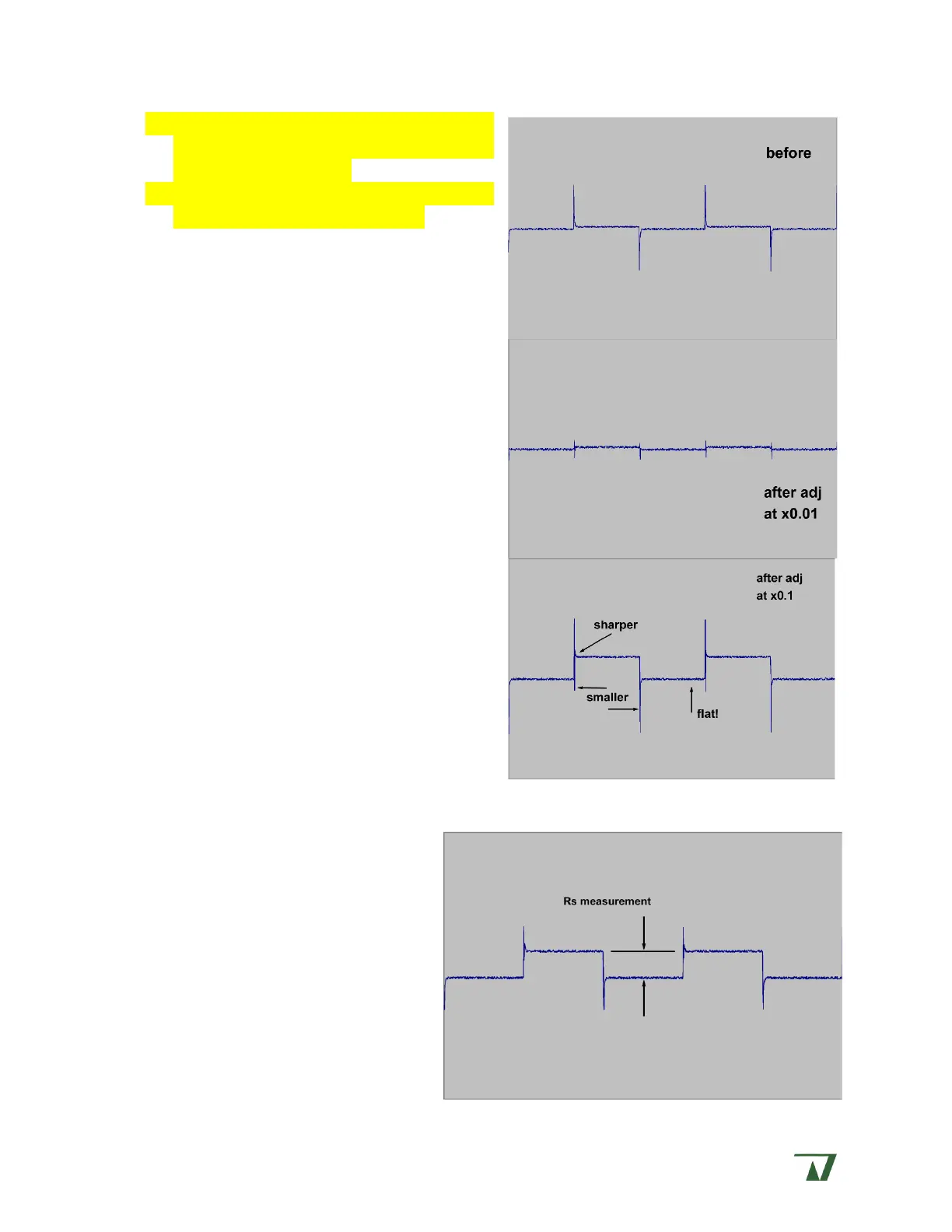

Set electrode capacitance compensation

Once a seal has formed, apply electrode

capacitance compensation.

Leave the TEST PULSE active and set the

COMMAND SENSITIVITY to x0.01 (10 mV). Adjust

your recording system so you can visualize the

trace as shown in the top figure to the right.

Use the FAST CAP COMP controls (C-FAST

and FAST ) to minimize the overshoot and

balance the shape of the excursions on the

waveform. Because the two banks of CAP COMP

controls (1, 2) interact with each other, some

trial and error in making a good adjustment is

required.

Compensation is optimal when the square

wave has as sharp a rise and fall as possible,

a flat top and bottom, and minimum

overshoot. (See the bottom figure on previous

page.) Rise time improves with higher

frequency BESSEL FILTER settings, however,

higher frequency settings introduce a tradeoff

between fast response and increased noise.

Once an optimal trace has been found at the x0.01 setting, increase the COMMAND

SENSITIVITY to x0.1 (100 mV) and

repeat. An appropriately adjusted

trace is shown to the right.

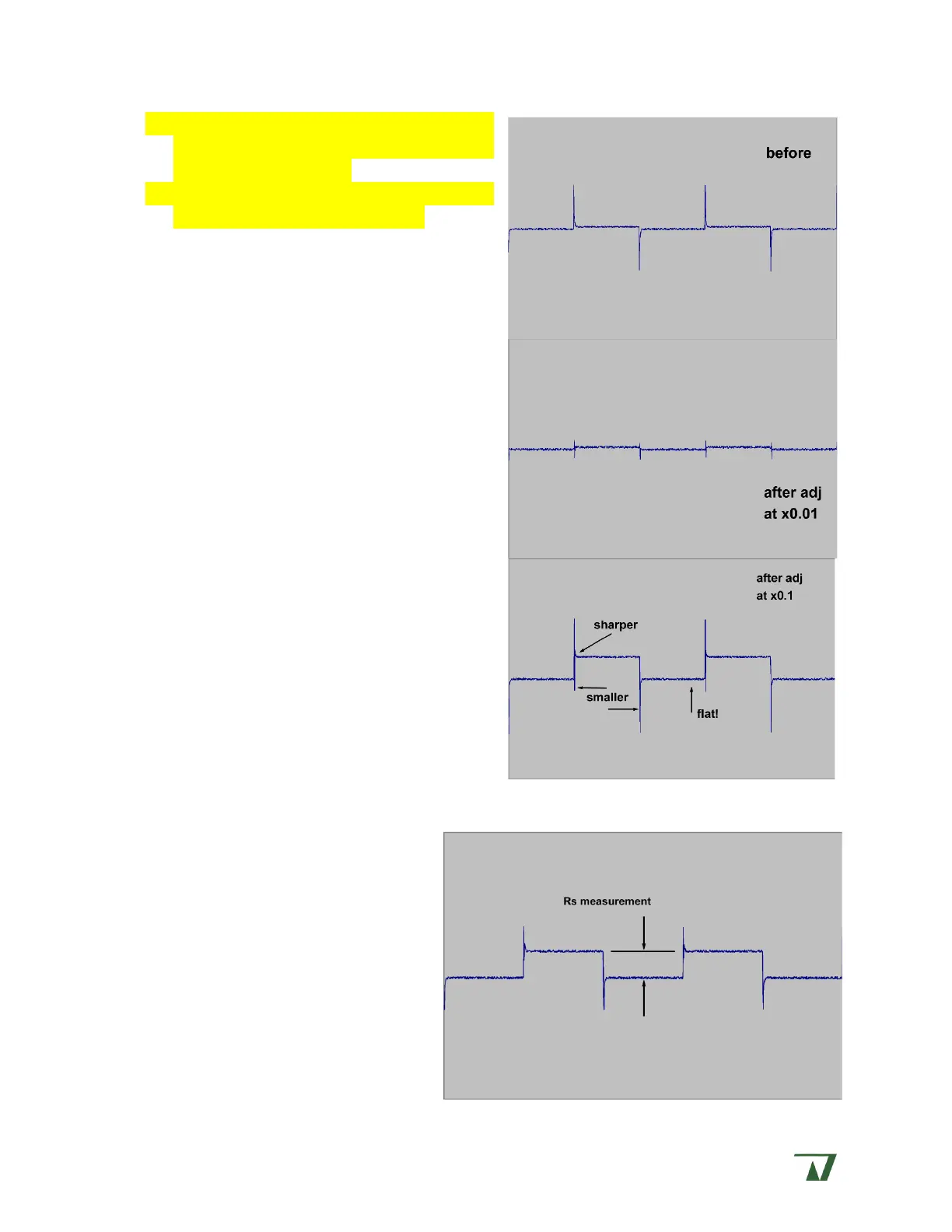

Measure seal resistance (RS)

You can measure seal resistance

with the electrode still attached to the

cell or after you’ve pulled a membrane

patch (cell attached patch or excise

patch configurations, respectively).

Keep the TEST PULSE on and

measure the peak-to-peak ‘leak’

Loading...

Loading...