Model

2001

SECTION

5

5.1

INTRODUCTION

This section provides information for testing, calibrating,

and trouble shooting the sweep generator. The performance

test

is

designed for incoming inspection and periodic evalua-

tion. If performance is not to specifications, refer to the

calibration and trouble shooting sections.

5.2

SERVICE INFORMATION

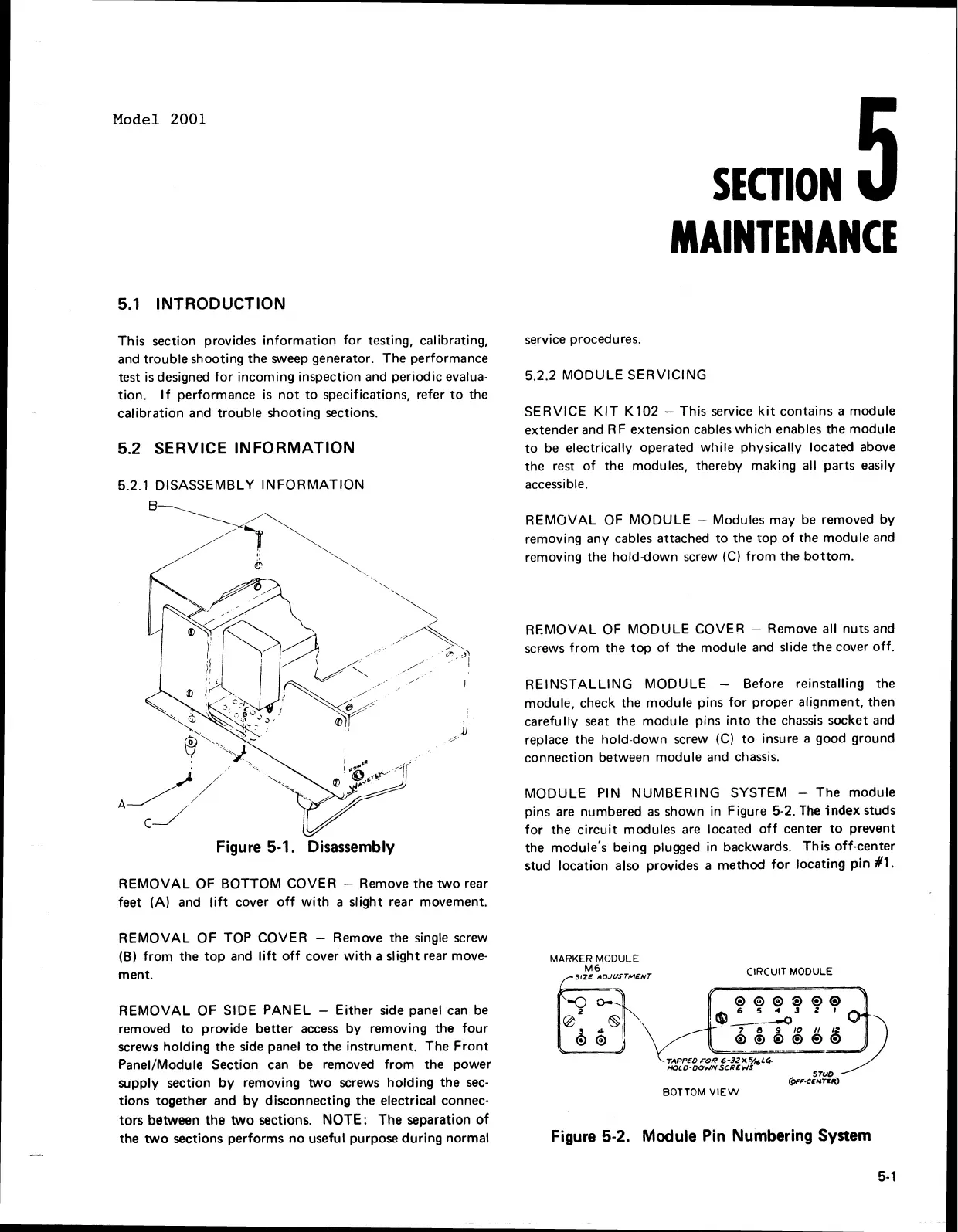

5.2.1

DISASSEMBLY INFORMATION

Figure

5-1.

Disassembly

REMOVAL OF BOTTOM COVER

-

Remove the two rear

feet (A) and lift cover off with a slight rear movement.

REMOVAL OF TOP COVER

-

Remove the single screw

(6)

from the top and lift off cover with a slight rear move-

ment.

REMOVAL OF

SIDE PANEL

-

Either side panel can be

removed to provide better access by removing the four

screws holding the side panel to the instrument. The Front

Panel/Module Section can be removed from the power

supply section by removing two screws holding the sec-

tions together and by disconnecting the electrical connec-

tors between the two sections.

NOTE:

The separation of

the two sections performs no useful purpose during normal

service procedures.

5.2.2

MODULE SERVICING

SERVICE KIT

K

102

-

This service kit contains a module

extender and

RF extension cables which enables the module

to be electrically operated while physically located above

the rest of the modules, thereby making all parts easily

accessible.

REMOVAL OF MODULE

-

Modules may be removed by

removing any cables attached to the top of the module and

removing the hold-down screw

(C)

from the bottom.

REMOVAL OF MODULE COVER

-

Remove all nuts and

screws from the top of the module and slide the cover off.

REINSTALLING MODULE

-

Before reinstalling the

module, check the module pins for proper alignment, then

carefully seat the module pins into the chassis socket and

replace the hold-down screw

(C)

to insure

a

good ground

connection between module and chassis.

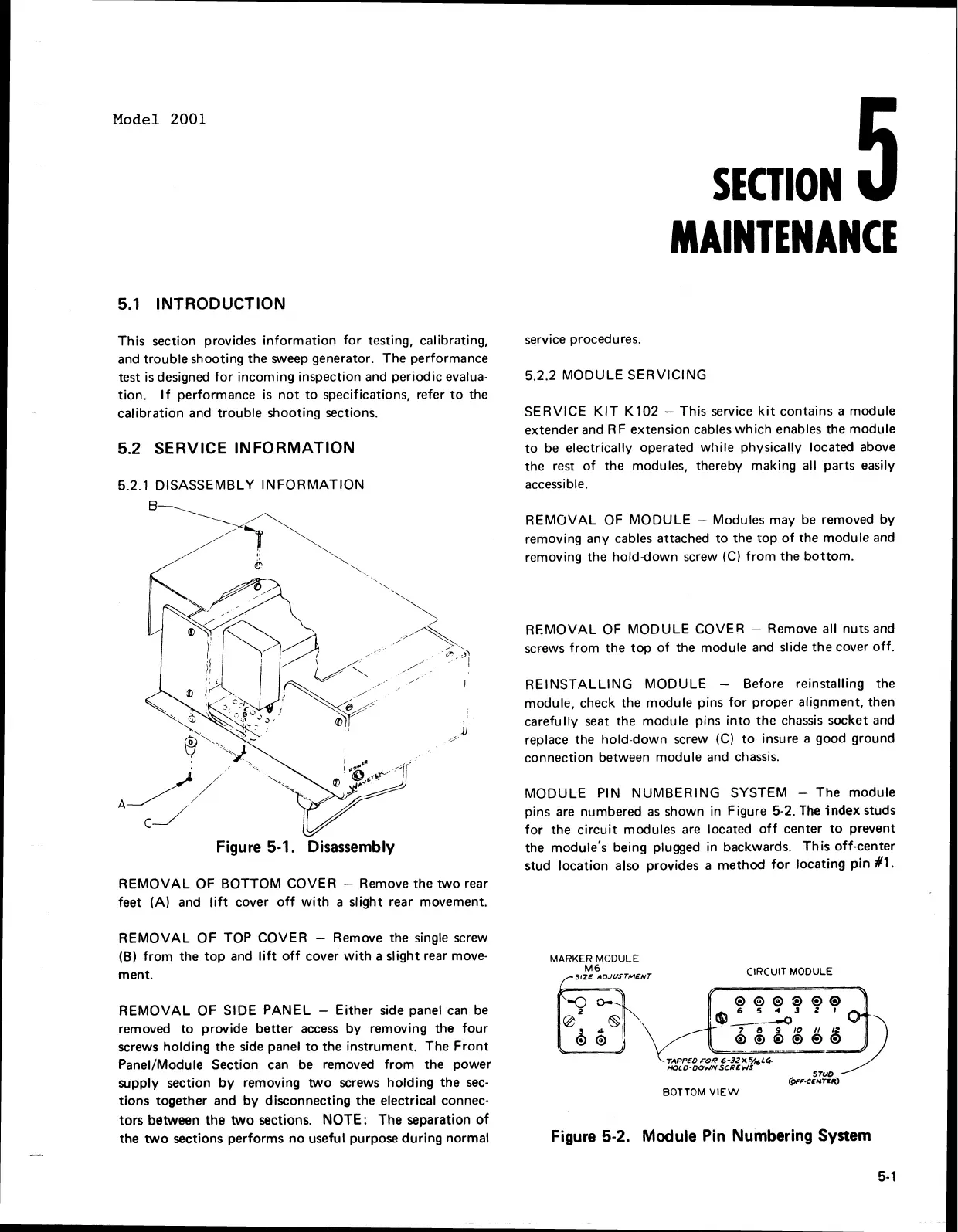

MODULE PIN NUMBERING SYSTEM

-

The module

pins are numbered as shown in Figure

5-2.

The

index

studs

for the circuit modules are located off center to prevent

the module's being plugged in backwards. This off-center

stud location also provides a method for locating

pin

$1.

MARKER

MODULE

M6

S~ZE

ADJUSTMENT

CIRCUIT

MODULE

E.;.

TlPPKOroR 6-3ZXVfiLCF

HOLD-OO*/NSCRbWS

BOTTOM

VIEW

Figure

5-2.

Module Pin Numbering System

5-

1

Model 2001

5.1

INTRODUCTION

This

section provides

information

for

testing, calibrating,

and

trouble

shooting the sweep generator. The performance

test is designed

for

incoming inspection and periodic evalua-

tion.

If

performance is

not

to

specifications, refer

to

the

calibration and

trouble

shooting sections.

5.2 SERVICE INFORMATION

5.2.1

DISASSEMBLY

INFORMATION

REMOVAL

OF

BOTTOM

COVER - Remove the

two

rear

feet (A) and

lift

cover

off

with

a slight rear movement.

REMOVAL

OF

TOP COVER - Remove the single screw

(B)

from

the

top

and

lift

off

cover

with

a slight rear move-

ment.

REMOVAL

OF

SIDE

PANEL

-

Either

side panel

can

be

removed

to

provide

better

access

by

removing the

four

screws

holding

the

side panel

to

the instrument. The

Front

Panel/Module Section can be removed

from

the

power

supply section

by

removing

two

screws

holding

the

sec-

tions

together and

by

disconnecting the electrical connec·

tors

between

the

two

sections.

NOTE:

The separation

of

the

two

sections performs

no

useful purpose

during

normal

service procedures.

SECTION

MAINTENANCE

5.2.2

MODULE

SERVICING

SERVICE

KIT

K102

- This service

kit

contains a module

extender and RF extension cables

which

enables the module

to

be

electrically operated

while

physically located above

the rest

of

the modules, thereby making all parts easily

accessible.

REMOVAL

OF

MODULE

- Modules may

be

removed

by

removing any cables attached

to

the

top

of

the

module

and

removing the hold-down screw (C)

from

the

bottom.

REMOVAL

OF

MODULE

COVER - Remove all nuts and

screws

from

the

top

of

the module and slide

the

cover

off.

REINSTALLING

MODULE

- Before reinstalling the

module, check the module pins

for

proper alignment, then

carefully seat the module pins

into

the

chassis socket and

replace the hold-down screw (C)

to

insure a good ground

connection between module and chassis.

MODULE

PIN

NUMBERING

SYSTEM -

The

module

pins

are

numbered

as

shown in Figure 5-2.

The

index studs

for

the

circuit

modules

are

located

off

center

to

prevent

the module's being plugged in backwards.

This

off-center

stud location also provides a

method

for

locating

pin

11.

MARKER MODULE

M6

SIZE

ADJUSTMENT

CIRCUIT MODULE

BOTTOM

VIEW

Figure 5·2. Module Pin Numbering System

5·'

Loading...

Loading...