10

PREPARATION OF COMBUSTION CHAMBER

Clean the combustion chamber thoroughly. Scrape and brush all heating surfaces and flue ways. Soot and fly ash are excellent

insulators and unless removed, the efficiency of the heating appliance will be impaired. Plugged or restricted flue passages

will prevent burner from operating properly.

Be sure water column and gauge on boiler are clean and water level is visible. In all cases make sure the pigtail to limit control

is clear. Safety pop valves on steam boilers and automatic relief valves on closed water systems should be thoroughly checked

to make sure they are in good working condition.

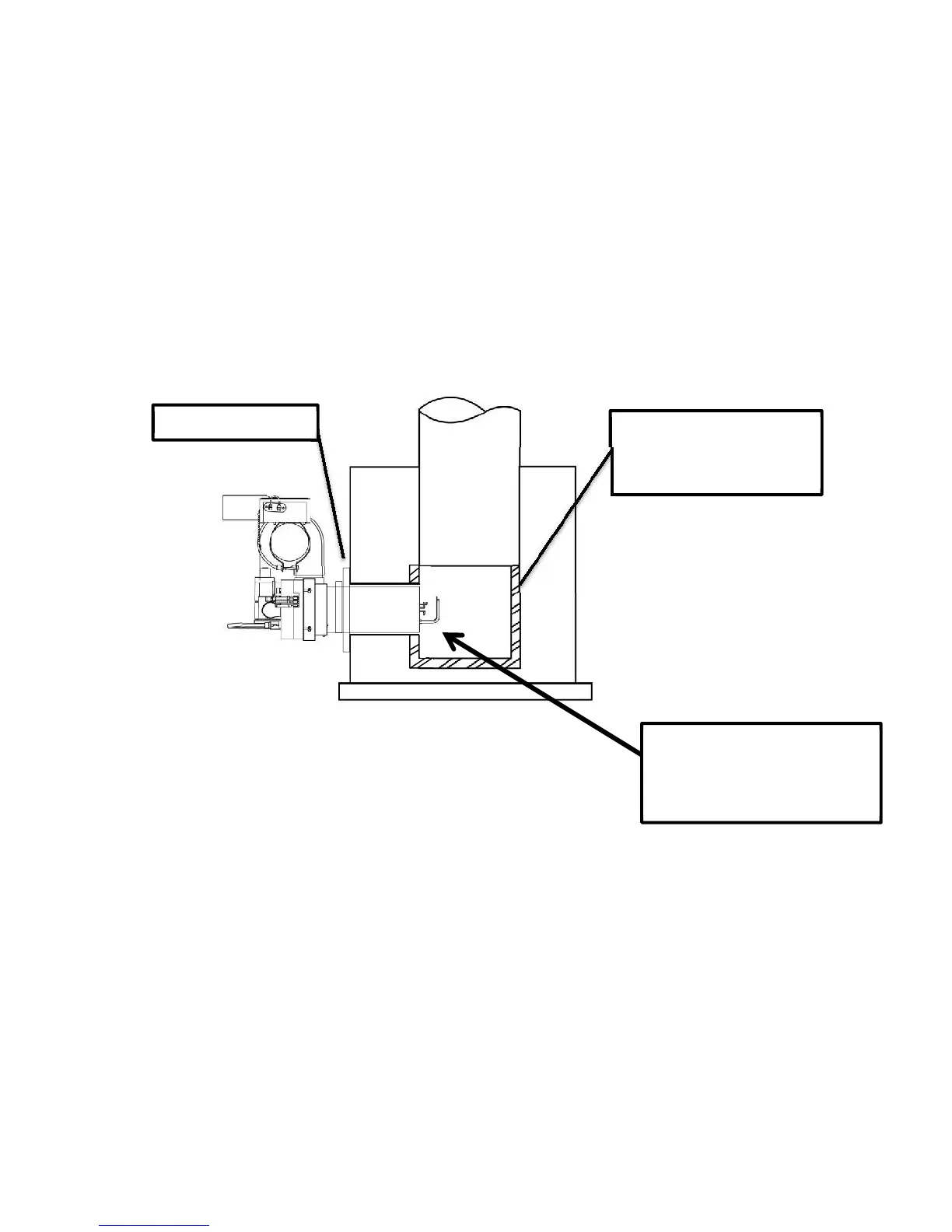

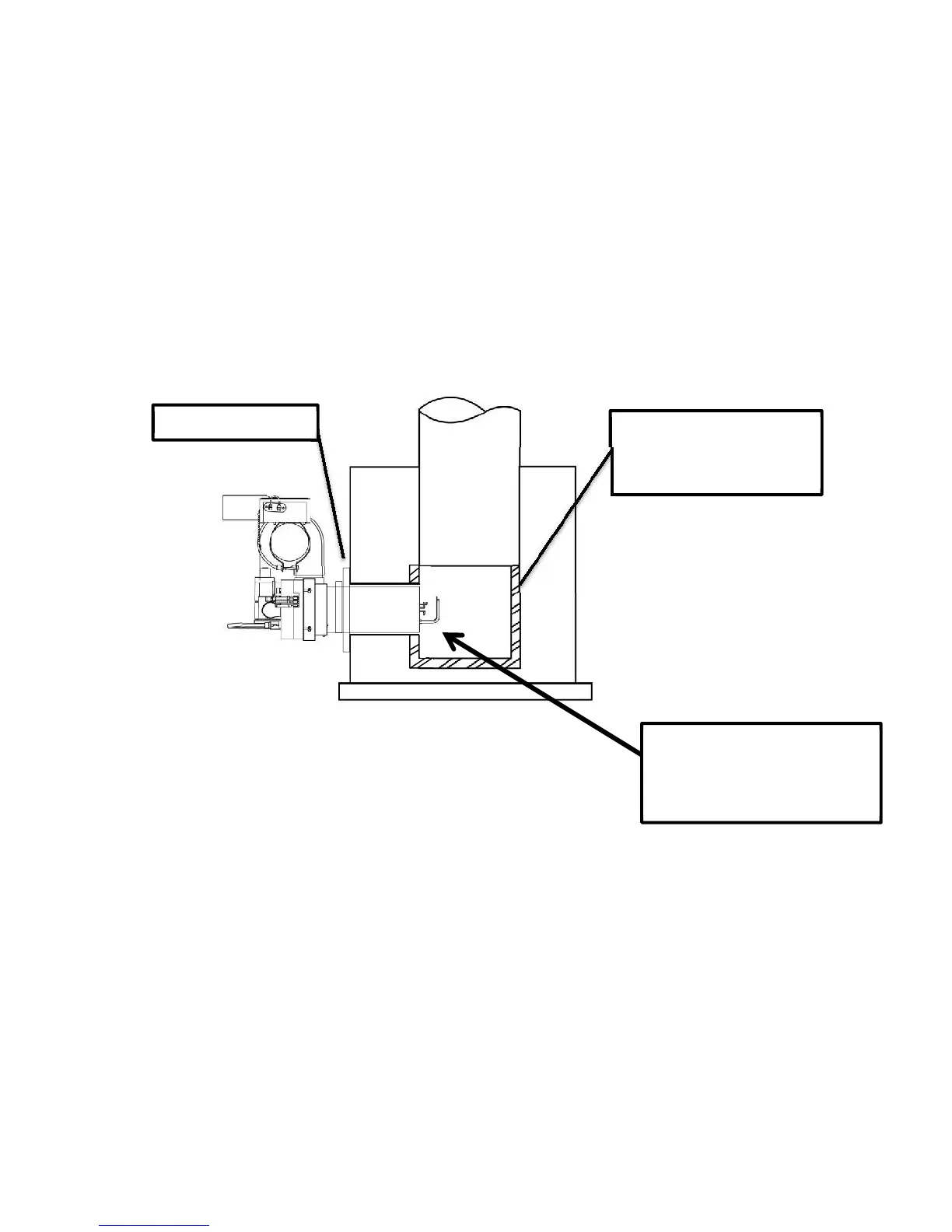

When converting oil designed boilers and furnaces, it is recommended that the existing combustion chamber be used with the gas

burner, provided it is in good condition. If the blast tube opening into the combustion chamber is larger than the 4” (102 mm) diameter,

high temperature cement should be used to reduce the opening to 4” (102 mm) diameter.

IN NO CASE SHOULD THE TUBE BE ALLOWED TO EXTEND INTO THE CHAMBER PROPER. IT MUST BE AT LEAST 1/8”

(3.2mm) SHORT OF THE INSIDE SURFACE OF THE COMBUSTION CHAMBER. (SEE FIGURE 5)

Loading...

Loading...