DETERMINE ORIFICE SIZE AND RATE

The gas conversion burner needs to be set to deliver the same amount of heat to the appliance as the oil burner it is replaci ng.

Determine the Btu/hr heat input rate for the appliance by locating the rating plate of the appliance and determine the firing rate

of the oil burner. Typically the nozzle in the oil burner is stamped with the gallon per hour rate. Use the lesser of these t wo

rates as the firing rate of the gas burner.

For calculating from gallon/hour of oil to Btu/hour of gas, One gallon of oil produces 140,000 Btu/gal (147700 kJ/L) of heat. For

example: A furnace rating of 0.60 G.P.H. would be 0.60 x 140,000 = 84,000 Btu/hr. This is the in put rate needed from the gas

burner.

Once the desired heat output of the burner has been determined, the gas orifice must be properly sized. The gas orifice

factory installed in all burners is sized to produce the minimum firing rate of the burner; 50,000 Btu/hr for the P250, 65,000

Btu/hr for the P265.

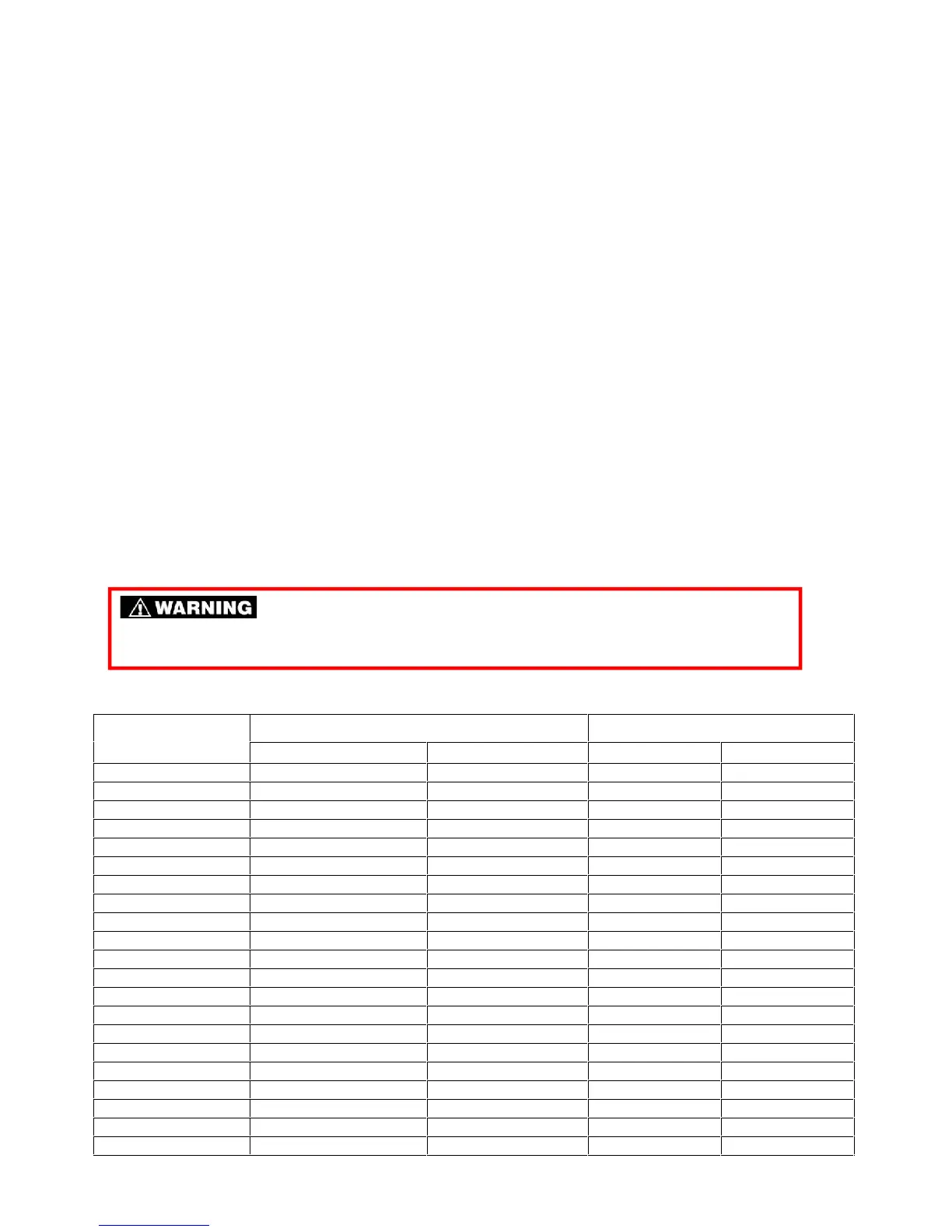

To determine the proper orifice size for the application, refer to Table 4 below. Locate the drill size by selecting the proper

column based on the gas to be used. Example: To fire 80,000 Btu/hr on natural gas requires an orifice drilled with a #19 drill

bit (0.166”).

NOTE: Numbered and lettered drill bit sizes are valid bit sizes. They are machinist’s drill bits. Decimal values have

been provided in Table 4 as assistance in determining closest fractional drill bit size to the number/letter drill bit size.

The correct manifold pressure for natural gas is 3.5” w.c (872 Pa). Only minor adjustments in the input rate should be made by

adjusting the pressure regulator. The minimum manifold pressure should be 3.0” w.c. (747 Pa) and the maximum pressure

should be 3.5” w.c. (872 Pa). The next size larger or smaller orifice size should be used if the desired input rating cannot be

obtained within the above manifold pressure adjustment range.

The correct manifold pressure for L.P. gas is 10” w.c. (2491 Pa). Only minor adjustments in the input rate should be made by

adjusting the pressure regulator. The minimum manifold pressure should be 9.5” w.c. (2366 Pa), the maximum pressure 10.0”

w.c. (2491 Pa). If the desired input rating cannot be obtained within the above manifold pressure and adjustment range then

the next size larger or smaller orifice size should be used.

Table 4: Orifice Size and Drill Bit Chart

Loading...

Loading...