Functional checks 41

7.2 Check for leaks in the system

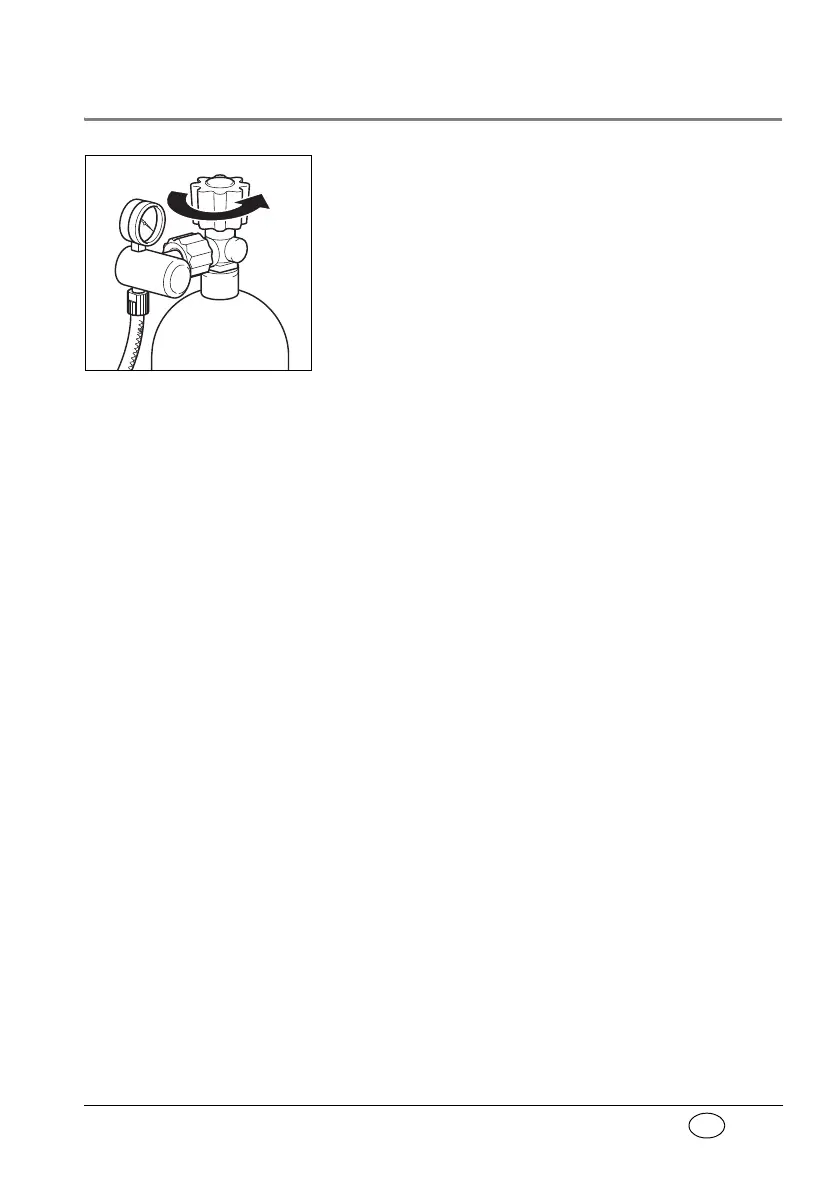

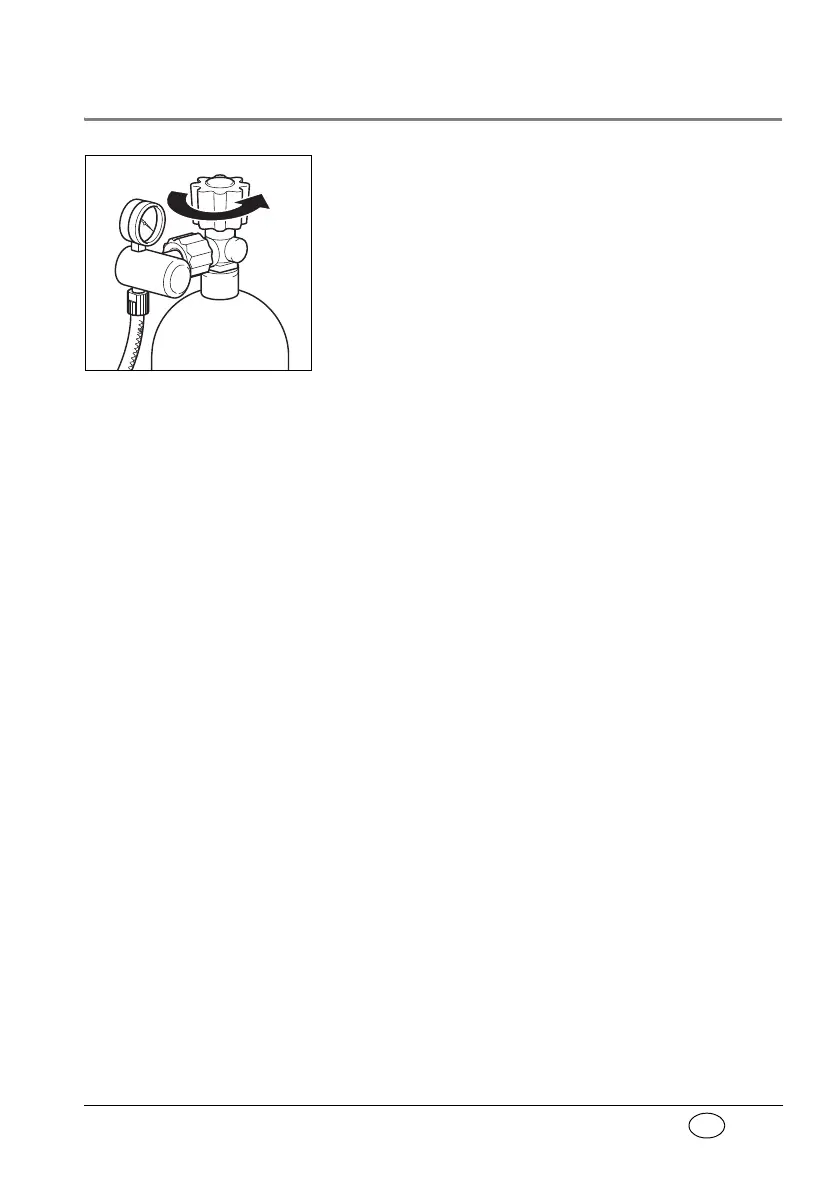

1. Open the valve of the oxygen cylinder slowly.

You will now be able to read the pressure in the

cylinder from the gauge on the pressure reducer.

For example, a reading of 200 bar means that

the cylinder is full, 100 bar that it is half full.

Always change the cylinder in good time, e.g.,

when the pressure is lower than 50 bar, to en-

sure that oxygen is available for an adequate

period.

2. Close the cylinder valve again.

3. Watch the needle of the gauge on the pressure

reducer for approx. 1 Minute. If it stays in the

same place, the system is free of leaks. If the nee-

dle drops steadily, there is a leak somewhere.

Repairing leaks

Always keep a stock of

washers for the connec-

tions available.

1. Prepare a soap/water solution using non-per-

fumed soap.

2. Wet all the screw and hose connections with the

solution. Bubbles will form at the site of the leak.

3. Depressurise the system:

To do this, first close the oxygen cylinder. Switch

on MEDUMAT Standard briefly until the pres-

sure gauge on the O

2

cylinder reads “0“. Then

switch MEDUMAT Standard off again.

Important note!

The screw connections on

the oxygen supply system

must be tightened by hand

only.

4. If leaks are discovered, the defective compo-

nents must be changed.

5. After changing, recheck the seal.

6. If it proves impossible to eliminate the leak, the

ventilator will have to be repaired.

Loading...

Loading...