Lit. No. 95748/95749, Rev. 04 20 January 1, 2017

MAINTENANCE

CONVEYOR BELT TENSION

The conveyor drive roller can slip inside the conveyor

belt for a number of reasons, including (1) material

trapped/frozen between the conveyor belt and the

vehicle bed surface, (2) frozen material in the hopper

and (3) improper belt tension. Before adjusting

conveyor belt tension, verify that material is not

trapped/frozen between the conveyor belt and the

vehicle bed surface and that frozen material is not

preventing the belt from operating properly. In either

of these situations, either the drive roller will slip or

the spreader control will sense an overload and will

shut down, signied by the diagnostic indicator light

ashing three times. See Operating the Spreader –

Cab Control section for details on the control and the

diagnostic indicator light.

1. Fully load the hopper with the material that will be

regularly used.

2. Briey test the spreader. If the drive roller slips

inside the conveyor belt or the conveyor belt does

not move, immediately turn the spreader OFF. If

the drive roller is not slipping and the conveyor

belt is moving, the conveyor belt tension is correct.

NOTE: Stop the spreader immediately if the drive

roller is slipping inside the conveyor belt. Running

the spreader when the drive roller is slipping can

damage the conveyor belt.

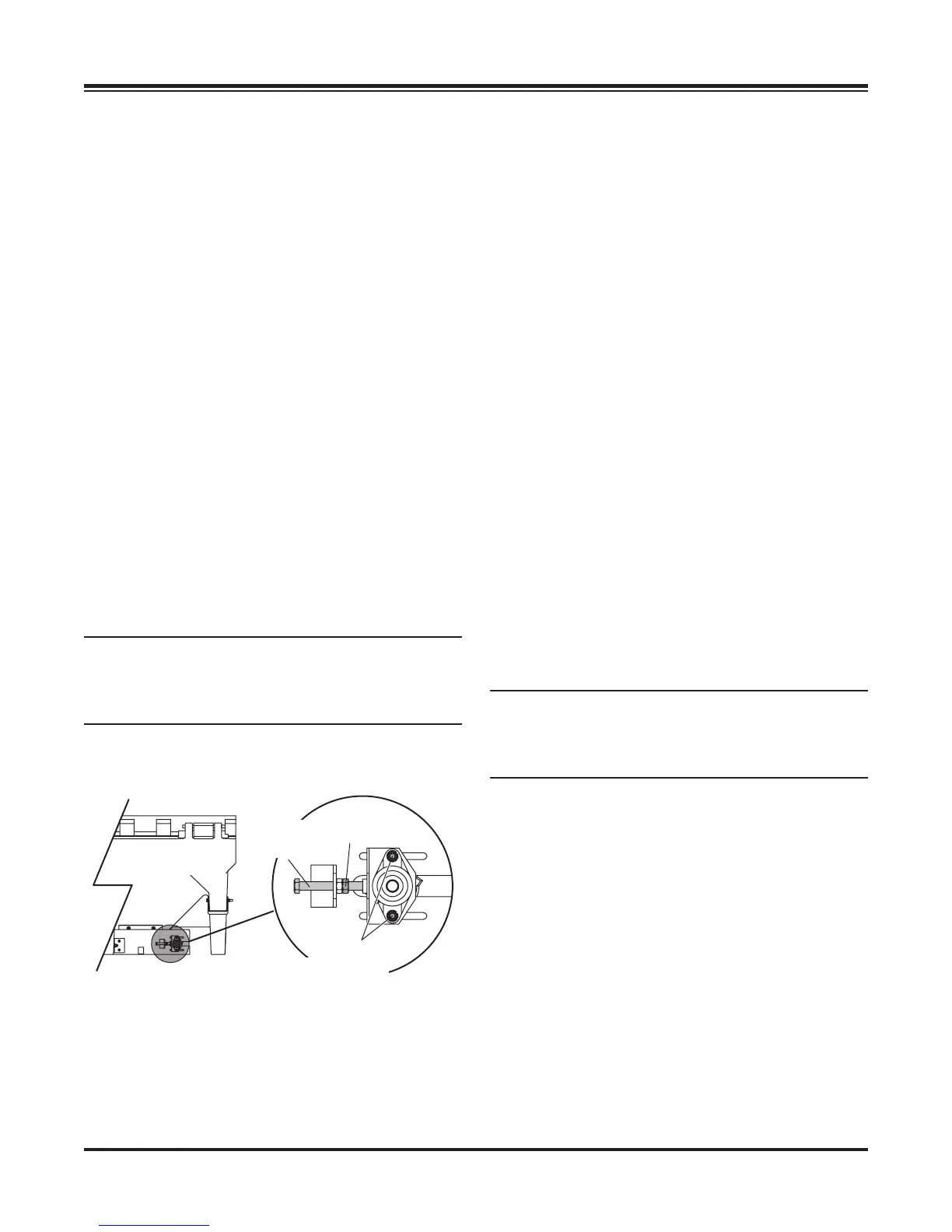

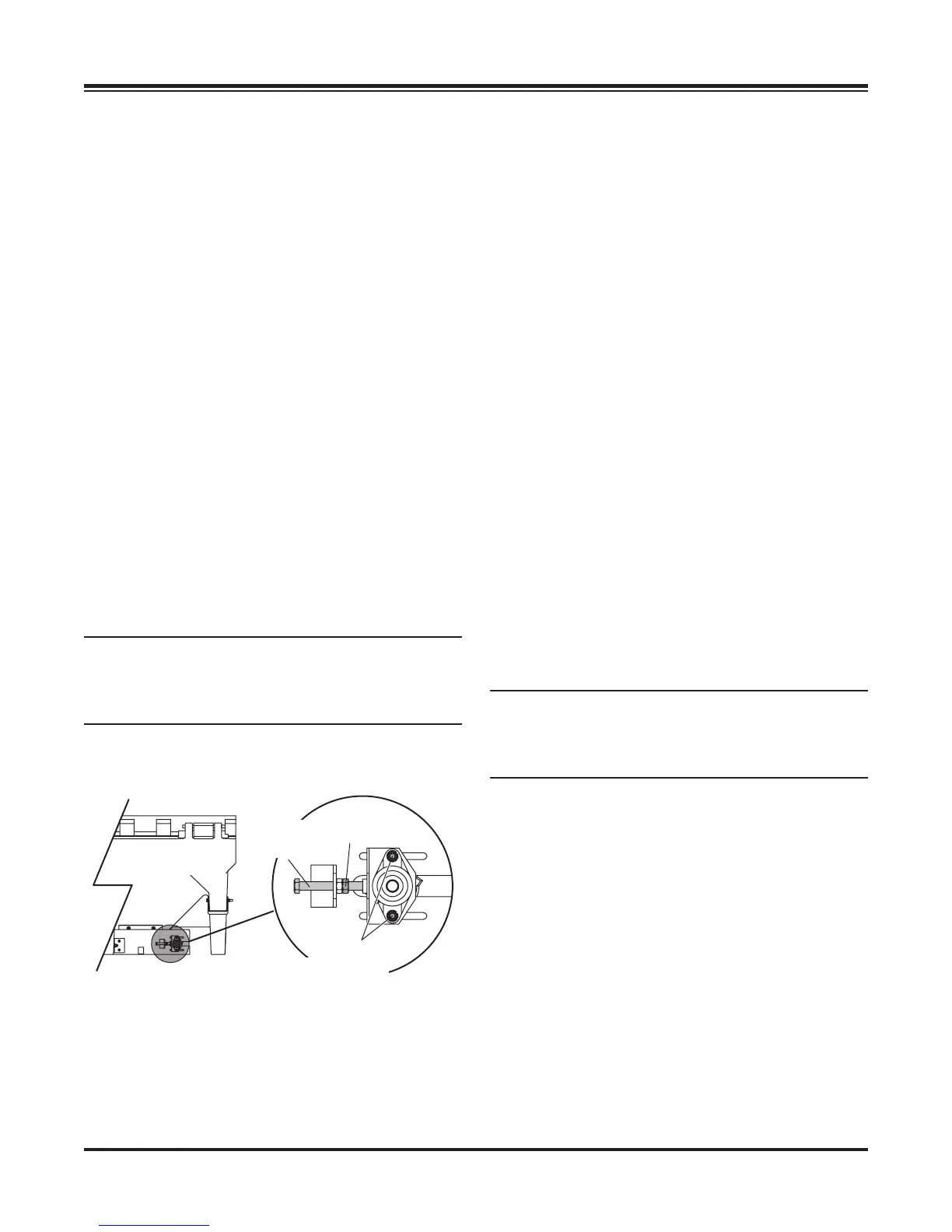

3. Loosen the two bearing mounting bolts on each

side of the conveyor idler roller.

4. Loosen the jam nut on one of the take-up bolts,

then tighten (clockwise) the take-up bolt one full

revolution. Repeat evenly on the other side.

5. Start the unit to determine if conveyor tension is

correct. If tension is not enough to restart the load

or if the conveyor drive roller slips, immediately

turn the spreader OFF and repeat the steps above

until the load restarts and the conveyor drive roller

does not slip.

6. Run the load for a few minutes and check the

conveyor idler pulley to determine if the conveyor

belt is running closer to one side than the other.

If the belt tracking is centered and the belt is not

rubbing on the side of the sills, retighten the jam

nuts and the bearing mounting bolts on both sides

of the conveyor idler roller.

7. If the conveyor belt is tracking off center, tighten

the take-up bolt on the side that the belt is tracking

towards. Sometimes it is necessary to overtighten

this side to make the belt track back toward center,

then loosen the take-up bolt slightly to maintain

center tracking of the belt. Once the belt tracking

is centered and the belt is not rubbing on the side

of the sills, retighten the jam nuts and the bearing

mounting bolts on both sides of the conveyor idler

roller.

NOTE: The conveyor belt may relax or stretch

after the rst few loads of material and may

require readjustment. Check belt tension after the

rst few loads and adjust as necessary.

Jam

Nut

Idler

Take-Up

Bolt

Bearing

Mounting

Bolts

Loading...

Loading...