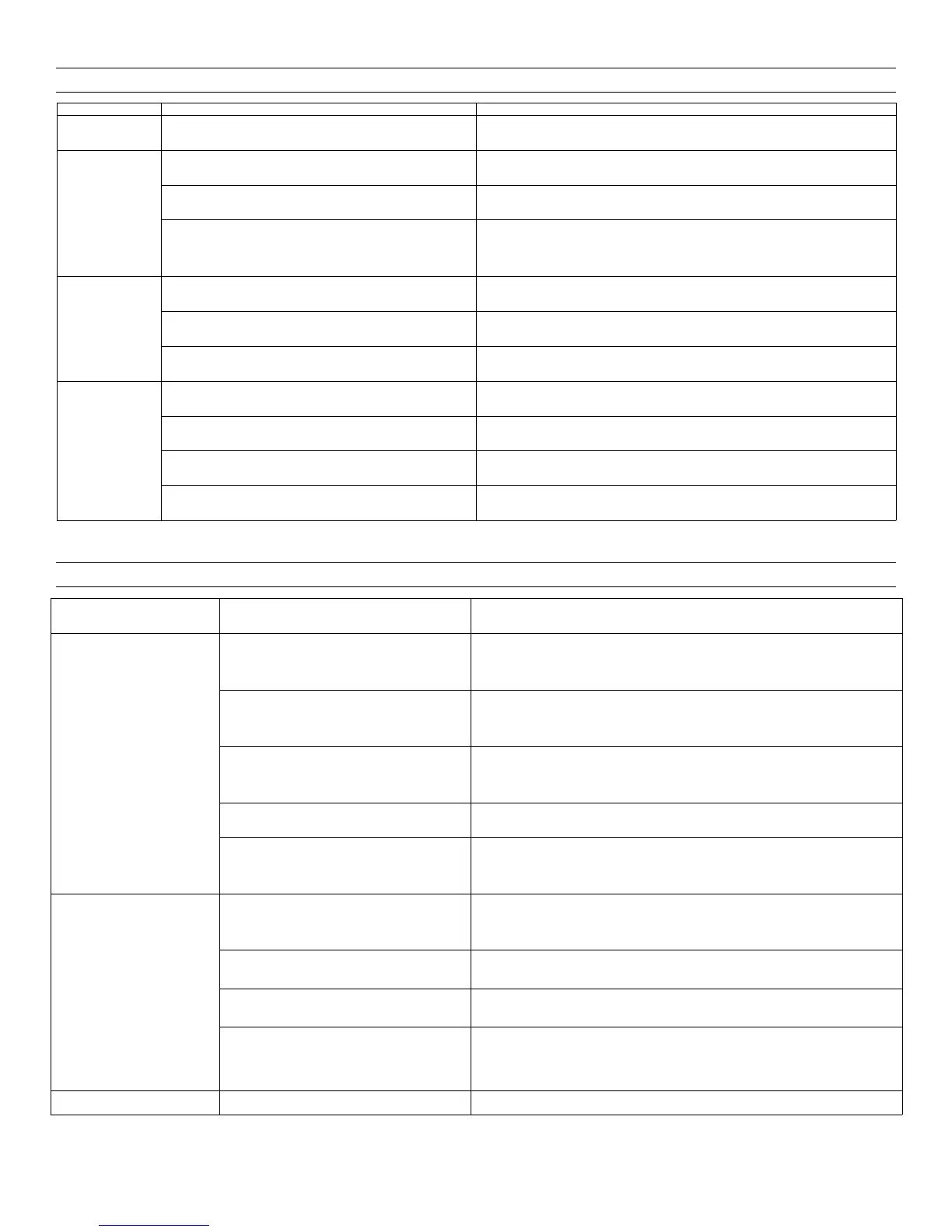

PAGE 21

Trouble Probable Cause Correction

Skipping

Stitches

Bent needle Discard and replace

Needle placed incorrectly in clamp See instruction page 7

Too fine a needle for thread being

used

See needle and thread chart, page 6

Irregular

Stitches

Upper thread tension too loose Tighten upper tension

Improper threading See threading instruction. page 7

Bobbin not wound evenly Rewind bobbin

Uneven

Stitches

Pulling or holding material Avoid pulling or holding material, just guide it.

Not enough tension on upper thread Increase tension

Poor quality thread Try different thread

Needle too fine for thread being used See needle and thread chart, page 6

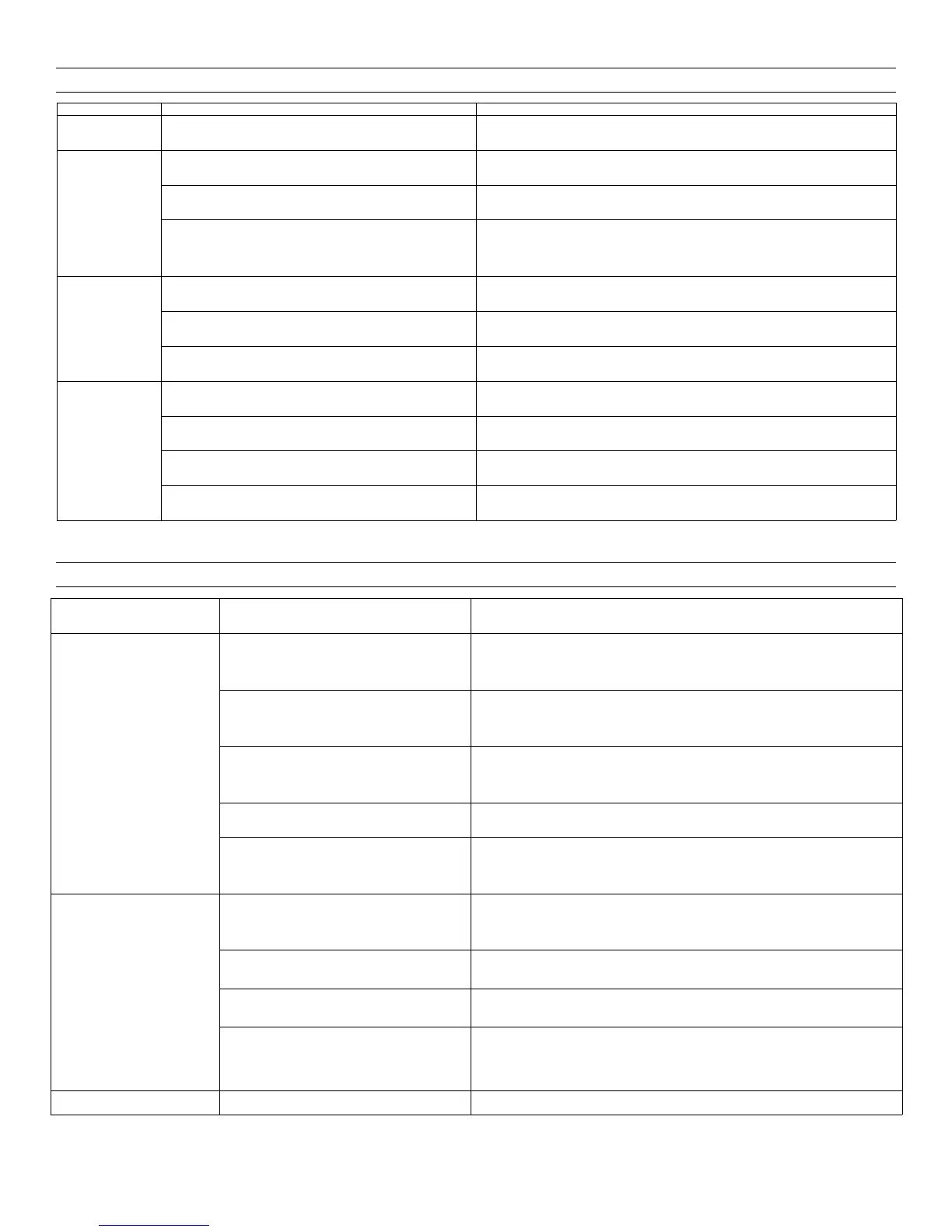

PAGE 22

Trouble Probable Cause Correction

Upper thread

breaking

Improperly threaded Refer to threading instructions on page 7 and re-

thread the machine

Too much tension Loosen tension on upper thread by turning thread

tension dial to lower number.

Starting with take-up in

incorrect position

Always start sewing with take-up lever in higher

position

Improper setting of needle Refer to needle setting instruction page 7

Bent needle, eye of needle

too sharp

Try a new needle

Material

puckering

Bent or blunt needle Discard all blunt or bent needles and replace with

new

Tensions too tight See tension adjustment page 10

Dull needle Change needle

Stitch length too long Reduce stitch length-some fabrics cannot be

sewed with a long stitch

Loading...

Loading...