PAGE 23

Trouble Probable Cause Correction

If Machine

Binds or

Locks

Thread or lint in race.

Likely machine was run

without sewing fabric.

Understandably, many users think their

machines have broken down the first time

they experience a clogged shuttle, or hook,

as sometimes described. However, such

jamming is easily corrected.

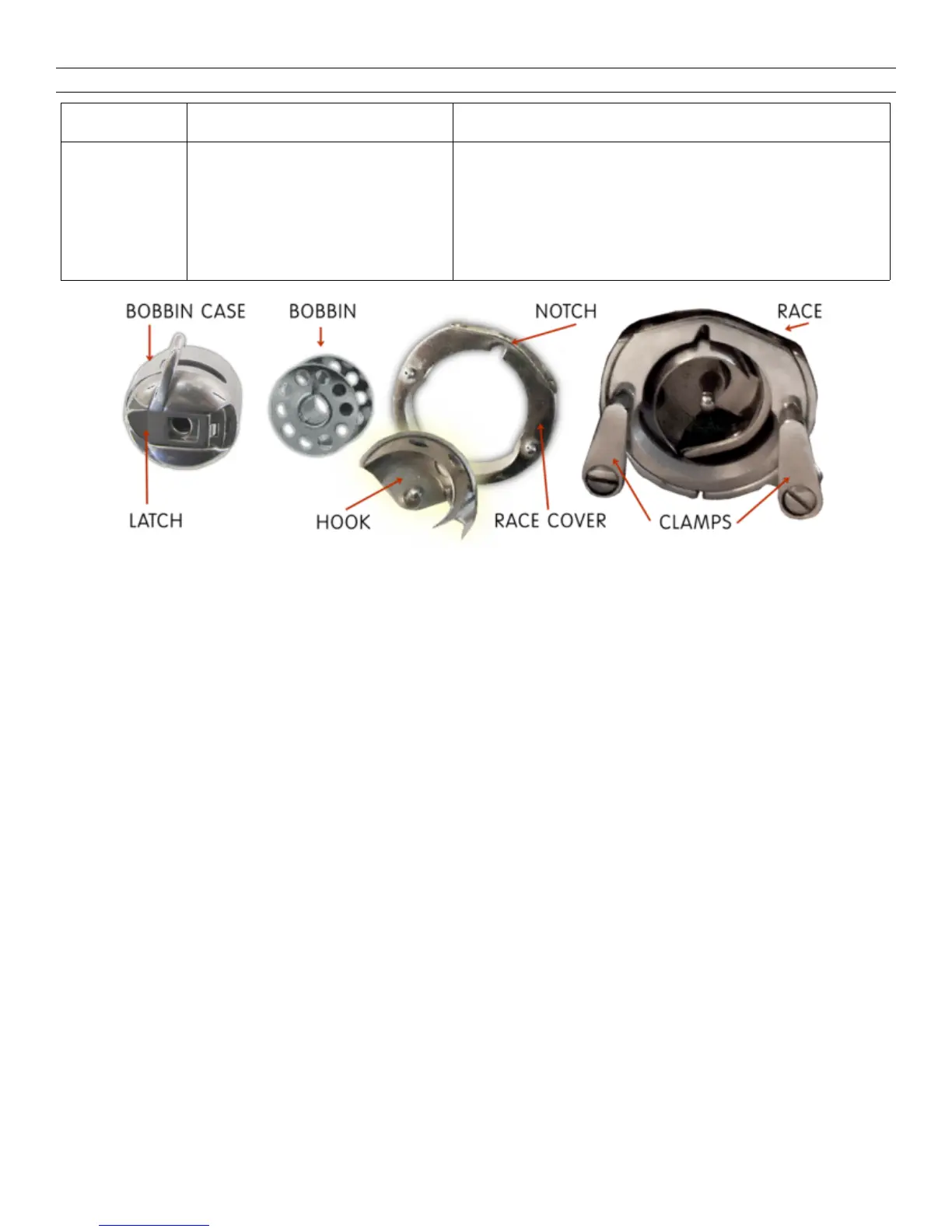

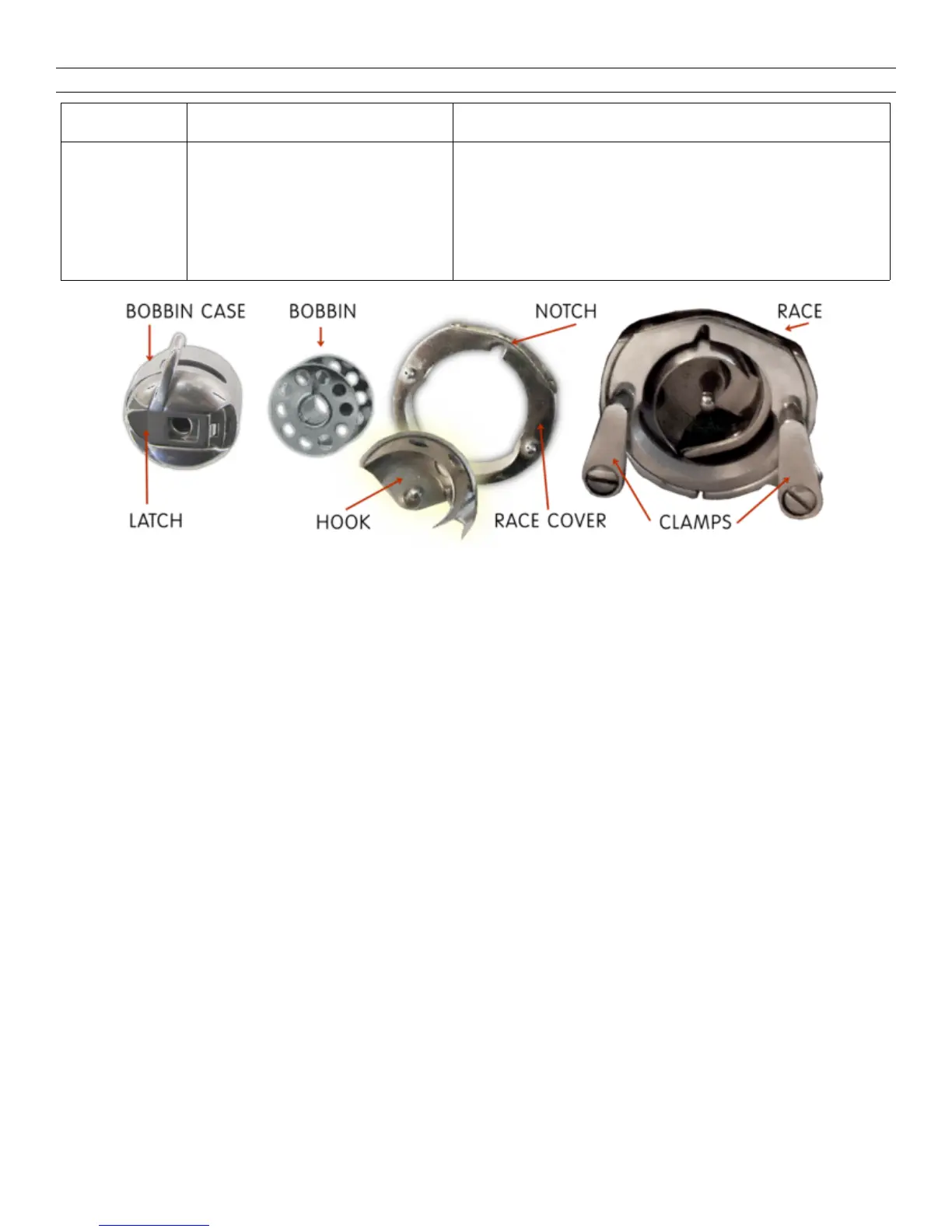

The bobbin case, shuttle race cover and shuttle (hook) must all be removed from the

shuttle race, which is built into the machine.

Move the needle and the take-up lever to their highest points. Next, lift and tip the

machine backward. It will remain at an upright angle resting on its cabinet or base

hinges — making the parts underneath the bedplate readily accessible. Lift the

fingernail-latch on the bobbin case and remove it from the machine. Push the top ends

of both of the race clamps outward (in opposite directions). Now the shuttle race cover

can be removed — usually dropping into your hands.

Finger-grip the center pin of the shuttle (hook) and remove it from the machine.

Thoroughly clean the shuttle race (in the machine), the race cover, and the shuttle

itself. If some scraping is necessary to get every bit of thread and lint removed from

edges or corners, be sure to cover the screw driver with a soft cloth. Before

reassembling all parts into the machine, put one drop of oil on a finger-tip then run the

finger tip around the outer edge of shuttle (hook). Avoid excessive oil on shuttle rim.

Any more than a film of oil may cause some oil to run into the bobbin case; soaking

and discoloring the bobbin thread.

When lowering the machine into its sewing position, grasp it with both hands ABOVE

the bedplate. Thus, you will not be risking scraped or bruised fingers should the

machine slip and drop too fast and hard.

Loading...

Loading...