Installation and operating instructions WILO Mather and Platt – VT pumps 21

4.3 Scope of delivery

Pump can be delivered,

• As a complete pump set including electrical motor, Sole

plate, coupling

• Either without motor or as bare shaft pump without sole

plate in case of existing sole plate and foundation

4.4 Accessories

• Companion Flange

• Foundation

bo

lts

• Shims

5. Product Description

Vertical turbine pump can be single stage or multistage in

construction. The pump is a vertical suction pump.

The unit is divided into three basic elements:

a. The pumping stages including bowl assembly.

b. Intermediate piping works and extension shafting.

c. Delivery bend & motor stool assembly.

The pumping stages are freely suspended from the delivery

bend by intermediate pipework, depending upon the site

conditions. In surface discharge installation, the delivery

bend & motor stool are placed above floor level. The thrust

bearing situated in the motor stool assembly supports the

static weight of the rotating assembly and also absorbs any

axial thrust that is developed within the unit during

operation. (Refer Fig. 10 & 17, Pg. No. 8 & 12) When the

pump is in operation, fluid is guided by a suction cover into

the impeller eye (inlet). Rotation of the impeller vanes

imparts energy to the fluid. This kinetic energy is converted

into pressure energy as the liquid flows through diffuser

vanes.

5.1 Casing

Casing consists of suction bellmouth and diffuser attached

together with impeller and replenishable rings. Casing

carries bush bearings to support shaft at regular intervals.

Depending on need bush bearings can be provided in

suction bellmouth. The top flange surface of casing carries

groove for O-ring for liquid sealing. Also, spigot is provided

on top flange for locating the components accurately.

5.2 Impeller

Impellers may be of mixed flow, Radial flow (open or close).

Refer specifications/datasheet/General arrangement

drawing/cross sectional drawing for details. The impeller

varies in size according to capacity of the individual pump.

Close type impellers are hydraulically balanced to reduce

axial thrust. Impeller carries balance holes and back vane for

thrust balancing. Balance holes can be plugged depending

upon the need. In case of open type of impeller, throat line

is provided below impeller. The gap between the same is

maintained as per pump manufacturer’s recommendations.

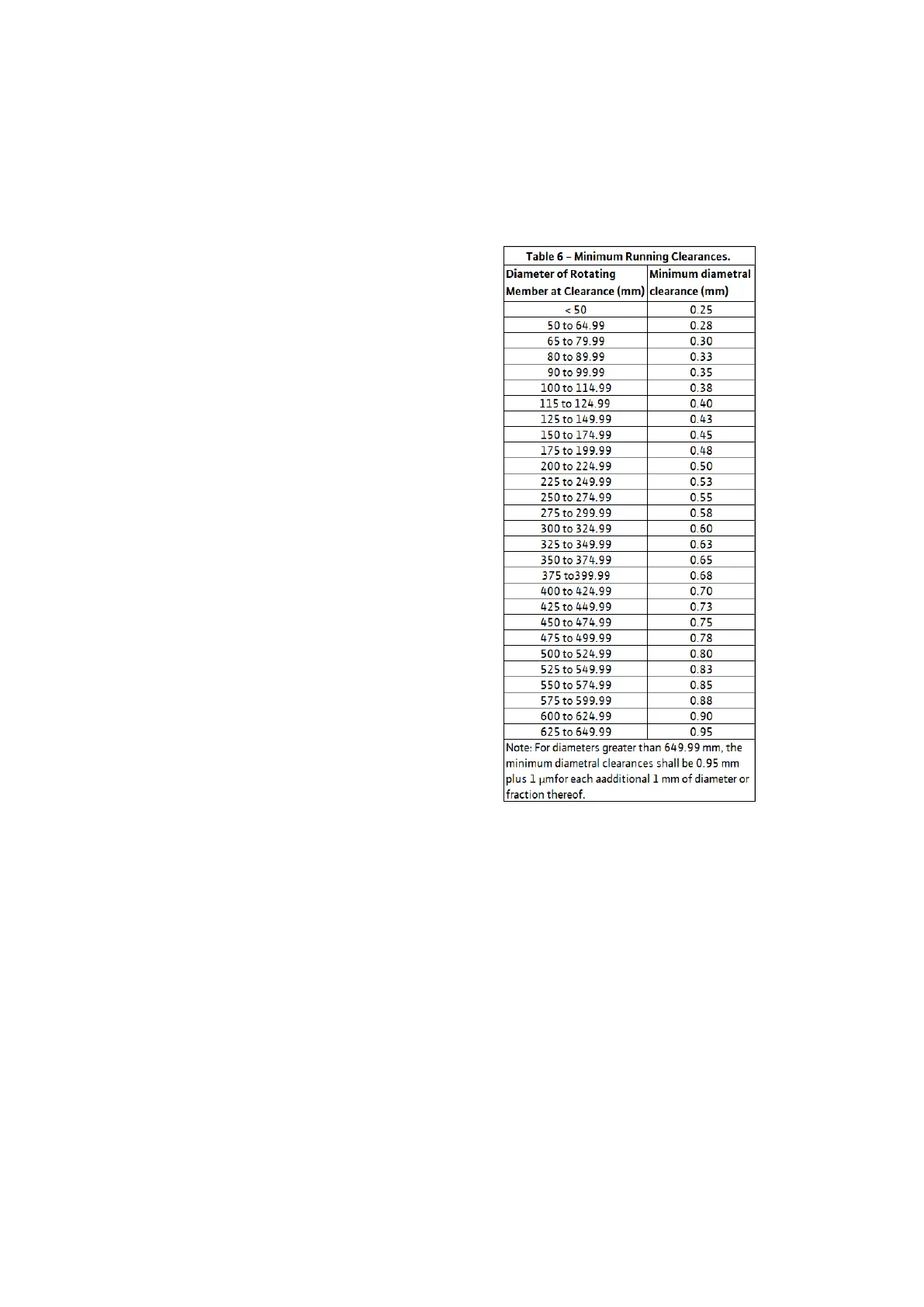

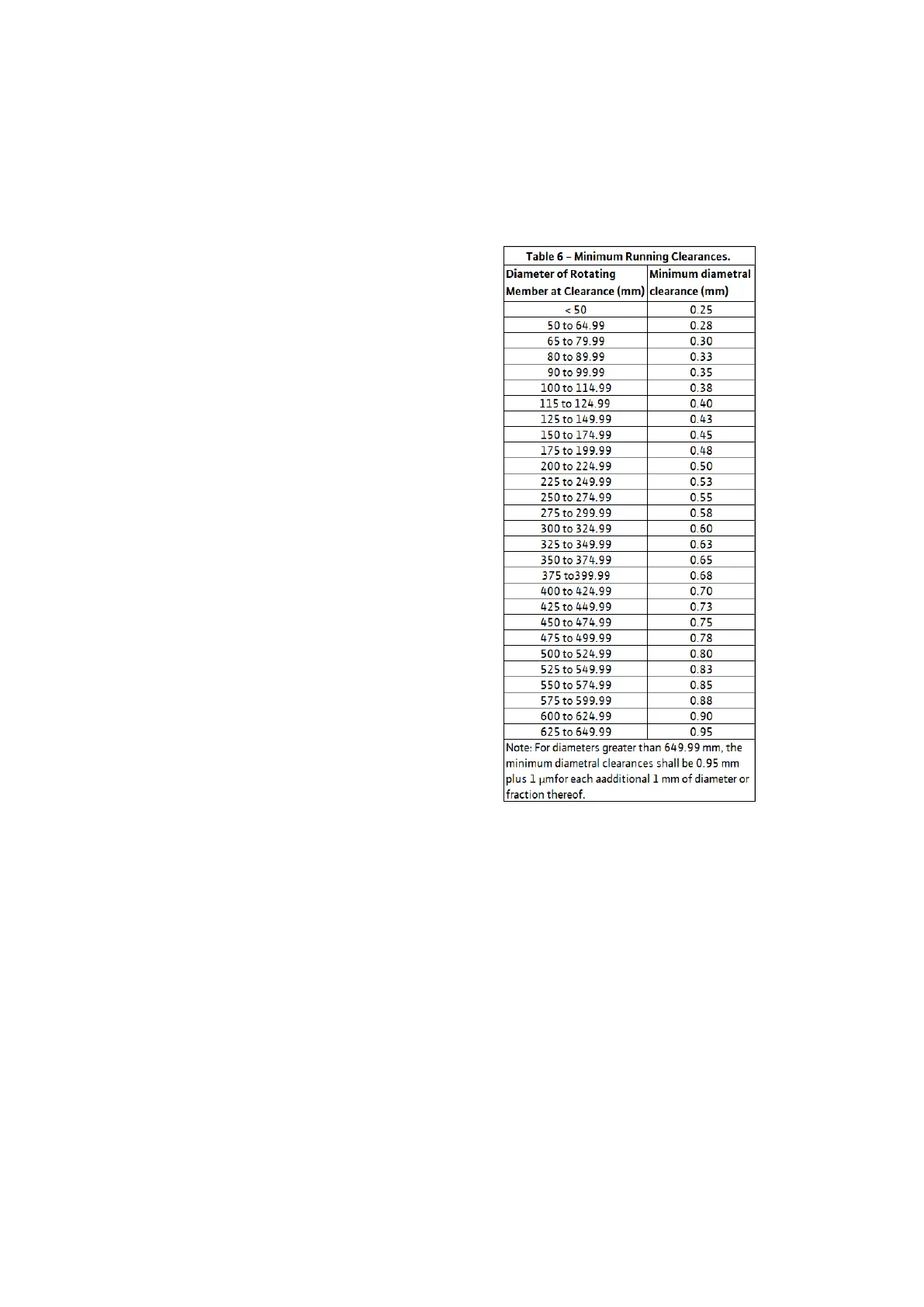

5.3 Impeller wear rings / neck rings

The impellers necks and casing are accurately machined to

provide a close running fit in the neck rings and wear rings that

surround them. The close clearance between the neck ring and

impeller neck as well as wear ring and casing minimizes the

leakage of fluid from the high-pressure areas to the low-

pressure areas of the pump.

Neck rings and Wear rings are renewable to allow this fine

clearance to be restored periodically as wear takes place. Ref.

Table 6 below,

5.4 Rotating Elements

The rotating element consists of the pump shaft, impellers,

intermediate extension shafting and solid muff couplings,

bearing and thrust block.

Impellers are keyed to the pump shaft and located axially. The

complete impeller and pump bearing sleeve assembly is end

tightened against step on the shaft by an impeller lock nut at

suction end. This lock nut is locked in position by locking screw.

Intermediate shafts are coupled together by solid muff

coupling. The weight of the whole rotor assembly is transferred

to bearing via thrust block. Float / lift of the pump can be

adjusted by adjusting thrust block lock nut.

5.5 Rising Main Pipe

Rising main pipes have flanged connections. Spigot joints are

provided in flanges to ensure concentricity. The top rising

column is connected to delivery bend. Grooves for O-rings are

provided for liquid sealing.

Loading...

Loading...