11.2 Overhaul maintenance

• After a long period of service, wear will occur in parts of

the pump, necessitating the renewal of a few

components. Logbook records will indicate wear as

gradual deterioration of performance is noticed. Once

this is known, pumps should be taken for overhaul. It is

recommended that yearly stripping & checking of wear

& tear and clearances should be done and overhauling

where required.

• If related pair of components show a marked degree of

wear in relation to the rest of the unit, then it may be

sufficient to renew only the heavily worn components.

If the wear is uniform throughout the pump, then all

wearable components may require renewal.

• Measurements should be taken and recorded of all

wearable components at the first, and every subsequent

overhaul period. Reference to these records will enable

an accurate assessment of the rate of wear to be made,

and a reasonably accurate forecast regarding when a

particular component may require renewal can be made.

• Information regarding original design dimensions and

clearances is furnished in data sheet. Any other

information, if needed, can be requested from Service

Department, WILO Mather Platt. Such requests must

quote name plate number and type of the pump in

question.

The parts most likely to be affected are:

• Impeller

• Mechanical seal

• Neck Rings

• Sleeves

• Stuffing Box Bush

• Bearings

• Coupling Bushes/ membrane set

Before commencing dismantling operations, ensure that the

following tools and tackles are available:

• A crane / chain pulley block suitable for handling the weight

of pumping unit.

• A selection of ring and open-ended spanners in

• British and Metric sizes.

• Eyebolts in British and Metric sizes.

• Cotton rope, wire rope and slings.

• Hardwood and metal packing blocks.

• Miscellaneous tools including a set of Allen keys, drills, pin

drivers, files etc.

• Extractor / puller for bearing and coupling.

• The torque value to be set for a particular size of screw is

dependent upon:

• Material of screw

• Parent metal

• Whether the screw is untreated or plated

• Whether the screw is dry or lubricated

• The depth of the thread

Tightening torques – Untreated Screw.

Coefficient of Friction 0.14

Property

cla

ss Torque

Nominal diameter-Coarse threads

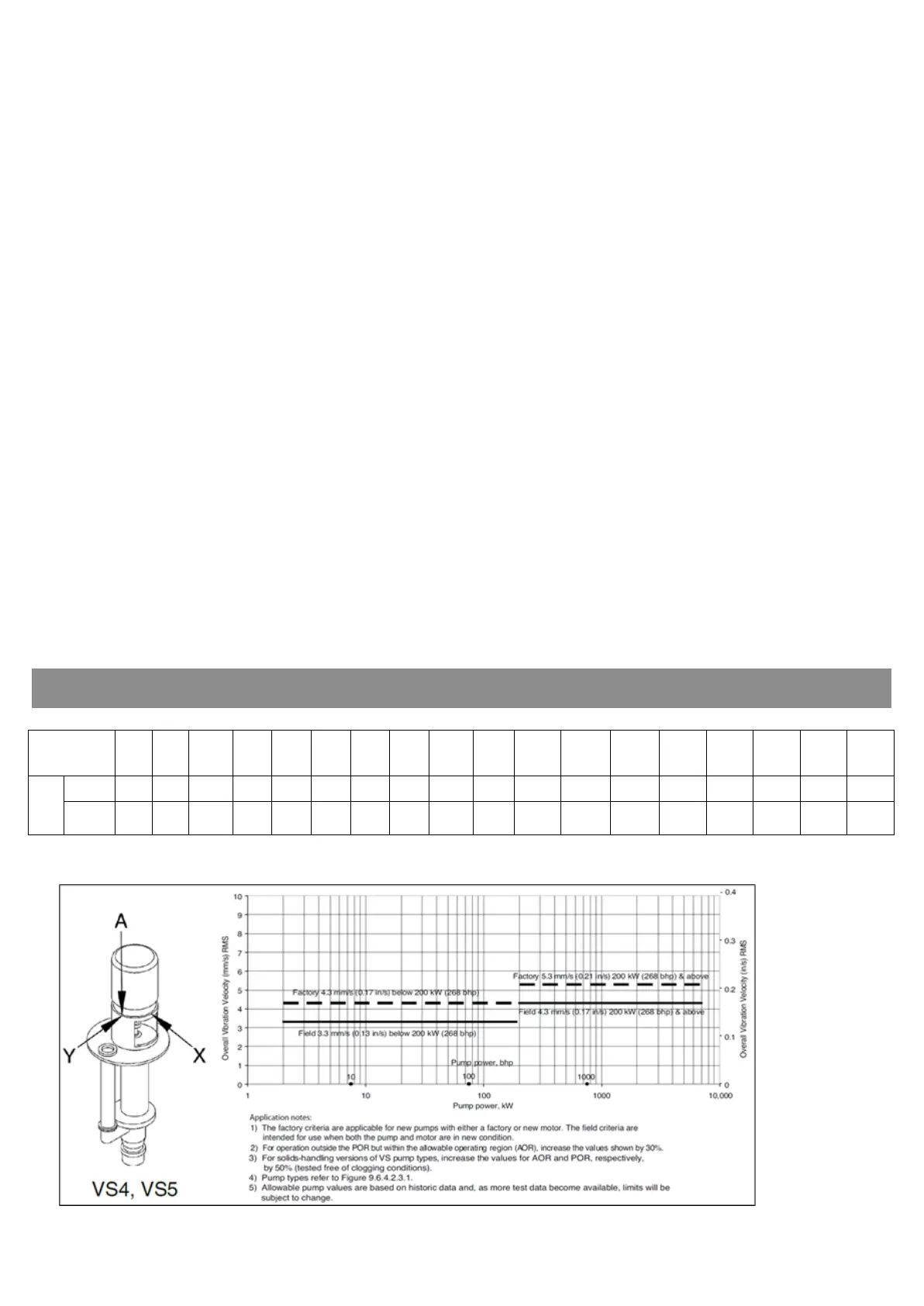

Hydraulic Institute Standard (HIS) ANSI/HI 9.6.4-2016

Acceptable field vibration limit chart (9.6.4.13)

Loading...

Loading...