Installation and operating instructions WILO Mather and Platt – VT pumps 25

7. Preparing Foundation

The foundation should be sufficiently substantial to absorb

any vibration and to form a permanent, rigid support for the

sole plate. The strength of foundation must be adequate for

the static and dynamic loads imposed and depend upon local

soil conditions. The foundation must get large dimensions.

Generally, the weight of the foundation is around 2 to 3 time

the pump set weight. In building the foundation, the top of

the foundation should be left approximately equal to sole

plate thickness plus 25 mm for packers/shims below, to allow

for grouting. Foundation bolts of the proper size should be

embedded in the concrete, located by template.

Note:

Leave top of foundation rough! Do not finish with trowel.

• A pipe sleeve about 2 ½ diameters large than the bolt should

be used to allow movement for the final positioning of the

bolts. For installations where a low level of noise is expected,

built the foundation in a pit lined with appropriate insulation

material in order to avoid vibration transmission to the

ground.

CAUTION! Risk of material damage!

While tightening pump screws/bolts, pump as well motor

should be free and should not be in coupled condition.

Pump or motor should not be used as supports while

tightening.

• Ensure that both Sole plate faces are parallel within

allowable value, free from any distortion as shown in fig.

Spirit level, straight edge along with engineer’s mater level

can be used to check flatness.

7.1 Sole Plate Installation

Sole plate has machined surfaces on both top and bottom

sides. The top surface of foundation over which the sole

plate rests must be left rough to assist in keying the final

grout. After the sole has been leveled by positioning steel

packer plates at suitable intervals on the foundation surface,

ensure that the surface beneath each packing plate is solid

by crushing any protrusion or alternatively each packer plate

may be placed on a thin screen of cement.

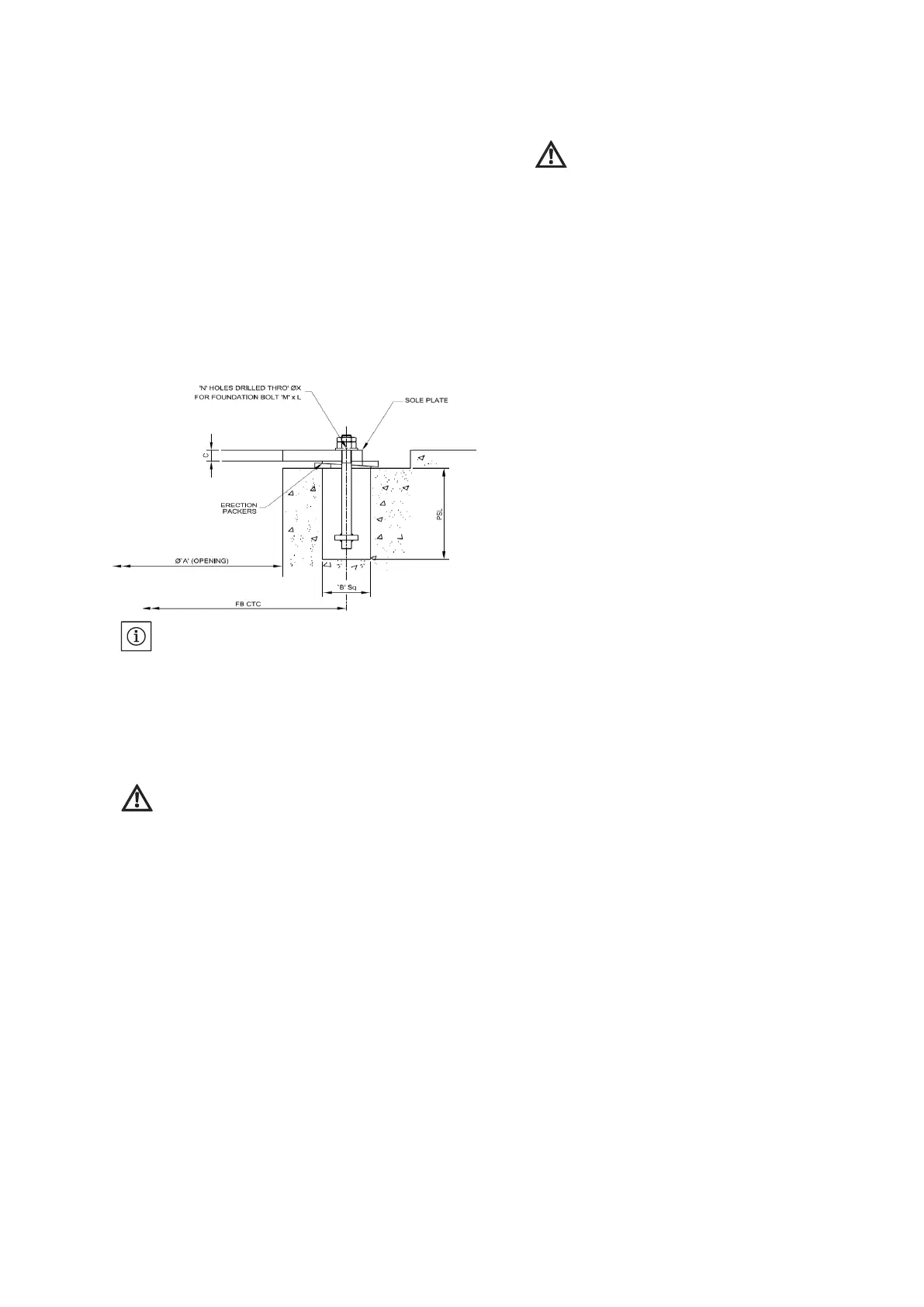

7.2 Levelling of Sole Plate (Fig: 7, Pg. No. 7)

CAUTION!

The machined surfaces where level is being checked

must be clean and free from paint, burrs etc.

Provide suitable packer plate (25 mm to 30 mm thick) or

taper wedges on the foundation one each of either side

of foundation bolt and in-between around 250 mm

center to center. It is advisable to provide thin layer of

cement below the packer plate.

• Lift the soleplate and lower it on the foundation. Insert

the foundation bolts through the holes in the soleplate

and screw a nut on to each bolt until the bolt protrudes

through the nut by a length, which is sufficient to

accommodate a lock nut.

• Adjust the level of the soleplate by inserting shims

between the soleplate and the packer plate until the

soleplate is leveled. And support on all the packing

wedges at suitable height. For checking the levels &

straightness, I-beam type straight edge should be used

extensively in conjunctions with engineer’s master level.

Level should be achieved within 0.02 mm per meter. Also

ensure that elevation of bedplate is adjusted suitably.

• For grouting use rich mix of 1:1:2 of cement, sand and

gravel below 12 mm, alternatively quick setting grout mix

can be used.

• When the grout has set, gently but firmly tighten the

foundation bolts. Do not to distort the soleplate or loosen

the foundation bolts in the grout by excessive tightening.

Carefully re-check the level of the soleplate and make

adjustments that are necessary by fine shimming. Ensure

that the sole plate is leveled, as per the site datum level,

various centerlines etc. (Refer Fig: 7 Pg. No. 7)

Loading...

Loading...