Installation and operating instructions WILO Mather and Platt – VT pumps 27

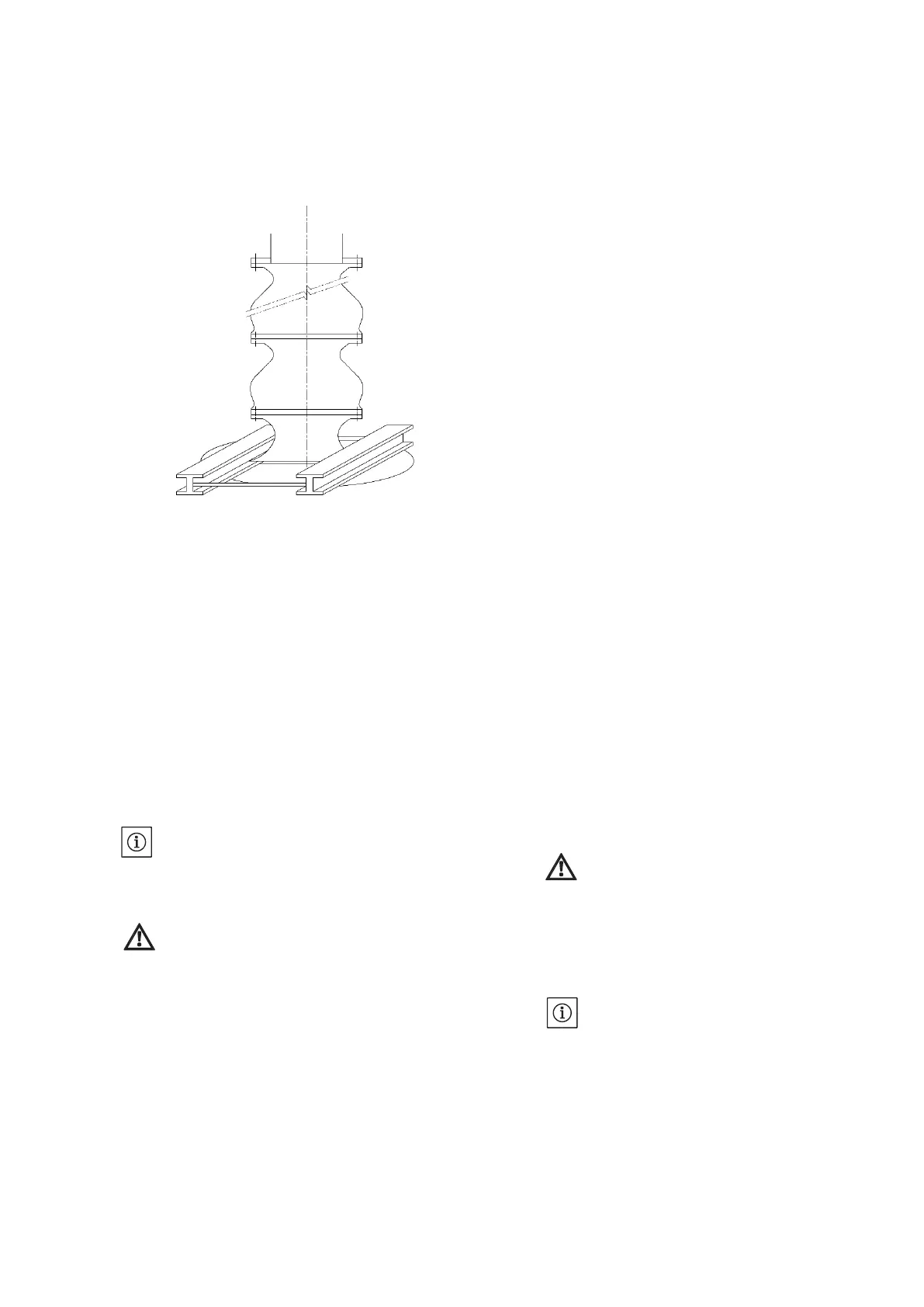

8.3 Installing a partially assembled pump

Depending upon column length of the pump it may not be

possible to dispatch the pump in fully assembled condition

and pump needs to be assembled at site in sequential

manner. For installation and assembly purpose suitable

beams are required to be placed across the opening over the

sole plate

• Lower the pump assembly, comprising of suction bell mouth

with suction strainer, casing & diffuser and rising main pipe

(bottom) in the sump with the help of sling and EOT crane.

Support the assembly on Beams placed across the opening

over the soleplate, (If necessary supporting channels must be

held together with help of tie rods).

• Couple first intermediate shafts with pump shaft by solid

muff coupling and split collar arrangement. (Refer Fig: 18 Pg.

No. 12)

• Lift first intermediate rising main pipe and lower on to the top

flange of bottom rising main pipe. Ensure that the ‘O’ rings

have been placed between the flanges. Insert screws & nuts

to tighten them.

• Take first intermediate bearing bracket and lower it on to first

intermediate shaft till it is located in groove of top flange of

bottom rising main pipe. Ensure that 'O' rings are fitted on

both sides of bearing bracket.

Note:

For column size more than 250 NB, fabricated intermediate

bearing spider integrated with column pipe is provided

instead of casted one.

CAUTION:

When strainer is attached to suction side of the pump, care

should be taken so that it should not damage while raising

the assembly in vertical position. Do not allow the suction

end to drag or support the total weight of assembled

pump.

• Slowly raise the whole assembly slightly, comprising of the

bottom rising main pipe and pump assembly, remove

channels and lower the assembly further into the sump till

supporting flanges or lugs of bottom pipe are rested on

channels across the sole plate opening

• Assemble 2nd intermediate shaft to 1st intermediate shaft

through muff coupling

• Take 2nd rising main pipe & lower it slowly with the help

of slings and crane on the bottom rising main pipe. Ensure

that intermediate bearing bracket is located correctly

• Insert bolts and nuts and tighten them properly and

evenly

• Assemble remaining shaft tubes (if provided), rising main

pipes and intermediate shaft is done in same way as

explained in seq. earlier.

• Lift delivery bend and lower on to the top flange of rising

main pipe. Tighten the fasteners. Care must be taken to

have a ‘O’ ring between two flanges

• Raise entire assembly, remove temporary support beams

and lower down till bottom flange of delivery bend rests

on sole plate & fix it with soleplate. Lift delivery bend and

lower on to the top flange of rising main pipe. Tighten the

fasteners. Care must be taken to have a ‘O’ ring between

two flanges

• Raise entire assembly, remove temporary support beams

and lower down till bottom flange of delivery bend rests

on sole plate & fix it with soleplate

8.4 Stuffing Box Installation (Refer Fig. No.15

Pg. No. 11)

• The stuffing box and gland sleeve should be thoroughly

cleaned and full entry of gland/mechanical seal into

stuffing box must be checked

• Gland packing arrangement - Insert three rings of gland

packing into stuffing box. Check if each ring of packing

length passes round the shaft and meets end to end, the

ends being cut square

• Insert logging ring in the stuffing box. Insert remaining

three rings of gland packing into stuffing box. Each ring

should be pushed into position individually using the

gland. The joint of each ring must be positioned at 180°

from adjacent ring

• Fit gland square with stuffing box and gland nuts should

be screwed up to little more than finger tightness. While

re-packing, if packing is available in complete coil form or

rope form, then the quantity required for immediate use

only should be taken. Each ring of requisite length should

be cut so that it passes once round the shaft and meets

end to end, the ends being cut square.

CAUTION! Risk of material damage!

Packing should be handled with care and it should not

be allowed to pick-up dust or abrasive foreign matter

by coming into contact with floors or dirty benches. It

is bad practice to hammer packing to facilitate the

insertion.

Note:

For Mechanical Seal installation, refer seal

manufacturer’s instruction manual.

Loading...

Loading...