and cutting surfaces.

18. All visitors should be kept at a safe distance from

the work area. Make workshop completely safe

General Electrical Cautions

This saw should begrounded in accordancewith the

National Electrical Codeand local codes and

ordinances. This work should be done by a qualified

electrician. The saw should be groundedto protect

the user from electrical shock.

by using padlocks, master switches, or by

removing starter keys.

19. Know the tool you are using, its application,

limitations, and potential hazards.

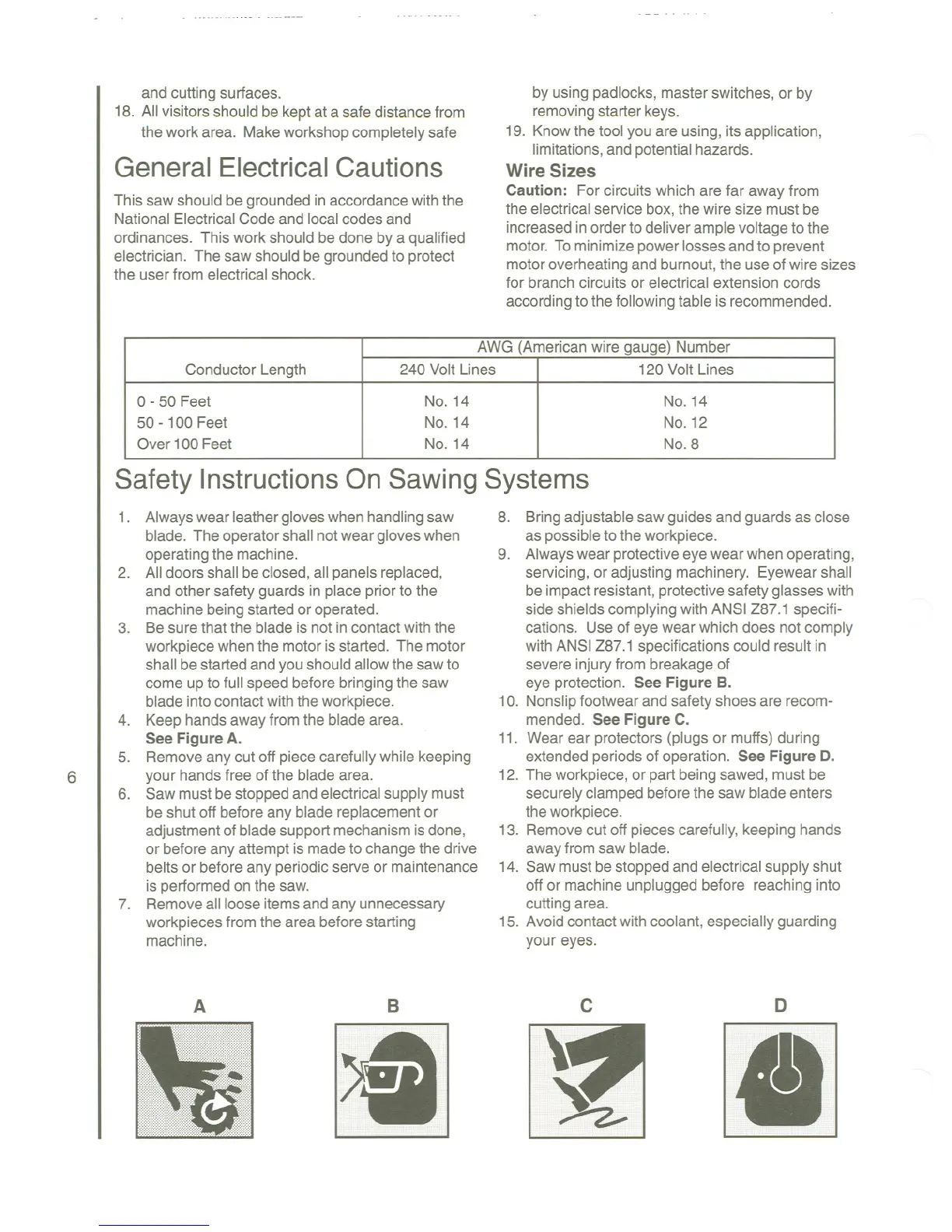

Wire Sizes

Caution: For circuits which are far away from

the electrical service box,the wire size must be

increased in orderto deliver ample voltage to the

motor. Tominimize powerlosses andto prevent

motor overheating and burnout,the use of wire sizes

for branch circuits or electrical extension cords

accordingto the following table is recommended.

Safety InstructionsOnSawing Systems

6

1. Alwayswear leathergloveswhenhandlingsaw

blade. The operatorshall notwear gloveswhen

operatingthe machine.

2. All doors shall be closed,all panelsreplaced,

and other safety guards in place priorto the

machine being startedor operated.

3. Be sure that the blade is not in contact with the

workpiece when the motoris started. The motor

shall be started andyou should allowthe sawto

come up to full speed before bringing the saw

blade into contact with the workpiece.

4. Keep handsaway from the blade area.

See Figure A.

5. Remove any cut off piececarefully while keeping

your hands free of the blade area.

6. Saw must bestopped and electricalsupply must

be shut off before any blade replacementor

adjustmentof bladesupport mechanismis done,

or before any attempt is made to change the drive

belts or before any periodic serve or maintenance

is performed on the saw.

7. Removeall loose itemsand any unnecessary

workpieces from the area beforestarting

machine.

A B

>8

8. Bring adjustablesaw guides and guards as close

as possibleto the workpiece.

9. Always wear protective eye wear when operating,

servicing, or adjusting machinery. Eyewear shall

be impactresistant, protectivesafety glasseswith

side shields complyingwith ANSI Z87.1 specifi-

cations. Use of eye wear which does not comply

with ANSI Z87.1 specificationscould result in

severe injuryfrom breakage of

eye protection. See Figure B.

10. Nonslipfootwear and safety shoes are recom-

mended. See Figure C.

11. Wear ear protectors (plugs or muffs) during

extended periods of operation. See Figure D.

12. The workpiece, or part being sawed, must be

securelyclamped beforethe saw blade enters

the workpiece.

13. Remove cut off piecescarefully, keeping hands

awayfrom saw blade.

14. Saw must be stopped and electricalsupply shut

off or machine unplugged before reaching into

cutting area.

15. Avoid contact with coolant, especiallyguarding

your eyes.

c D

.

AWG (Americanwire gauge) Number

Conductor Length

240 Volt Lines 120 Volt Lines

0 - 50 Feet No. 14 No.14

50 -100 Feet No. 14 No.12

Over 100Feet No. 14

NO.8

Loading...

Loading...