4. Referto Optional Welder for a description of the

welder controls.

The Model 8020 band saw is equipped with a two-

speed gearbox. The shift lever is located on the front

of the band saw. Shift positions are L (low) and H

(high).

The Model 8120 band saw is equippedwith a three-

speed gearbox. The shift lever is located on the front

of the band saw. The shift positions are L (low), M

(medium), and H (high).

Optional Blade Welder

An optional blade welder is available on the vertical

band saw. The welder has all the features required to

cut, weld, and anneal the saw blade.

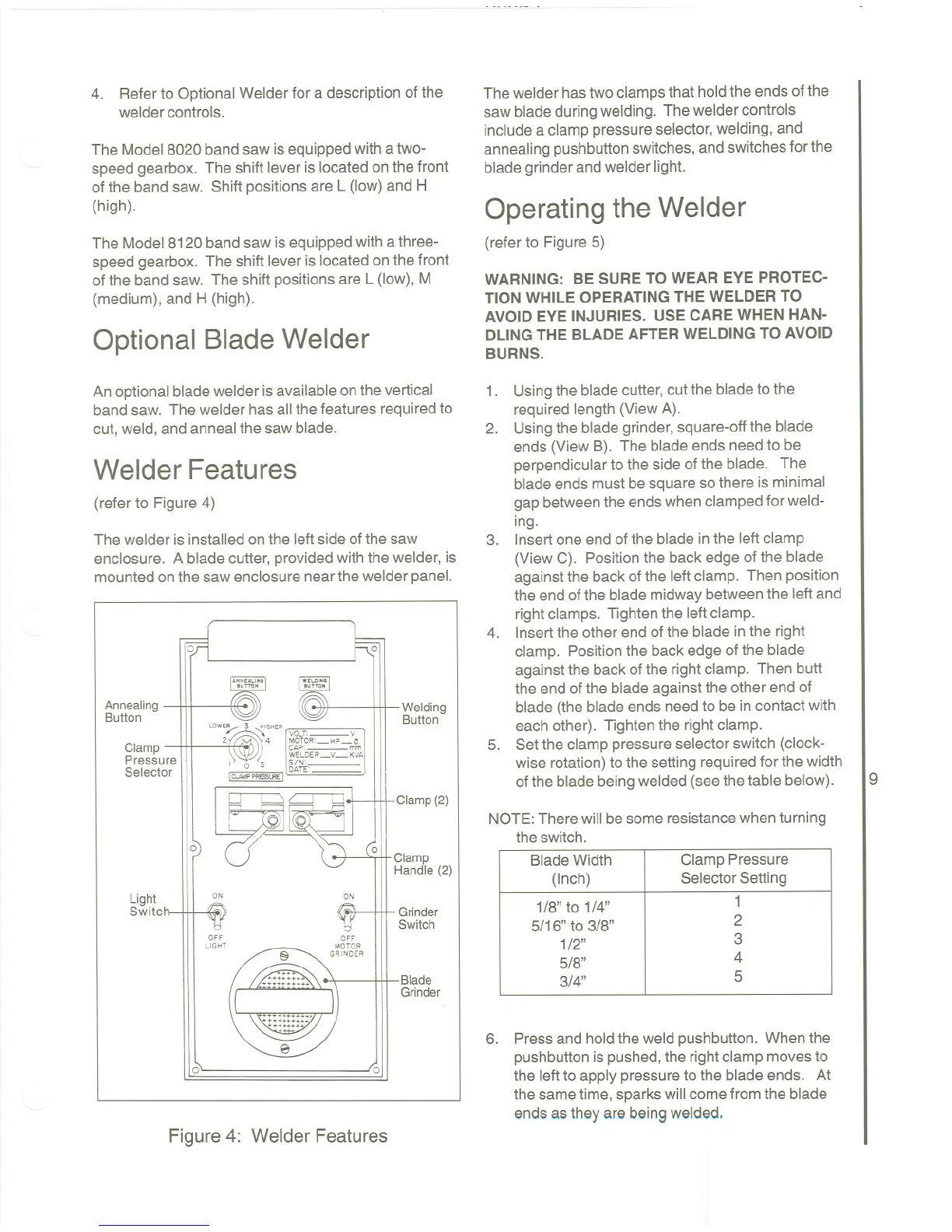

Welder Features

(refer to Figure 4)

The welder is installed on the left side of the saw

enclosure. A blade cutter, provided with the welder, is

mounted on the saw enclosure near the welder panel.

0 0

'"''''''

"Tro,

Welding

Button

Annealing

Button

Clamp

Pressure

Selector

LOWE/::

~

H'GHER

[

VOLT'- Y

2~ 4 MOTOR'-HP_~

\\'::Jf~ ~fLDELy_~w.1

I 0 5 5~~~'

IClA'.\P P"""LRE I

Clamp (2)

0

01,

Clamp

Handle (2)

Light

Switc

ON

ON

Grinder

Switch

OFF

LIGHT

Blade

Grinder

0

0

Figure 4: Welder Features

The welder has two clamps that hold the ends of the

saw blade during welding. The welder controls

include a clamp pressure selector, welding, and

annealing pushbutton switches, and switches for the

blade grinder and welder light.

Operating the Welder

(refer to Figure 5)

WARNING: BE SURE TO WEAR EYE PROTEC-

TION WHILE OPERATINGTHE WELDER TO

AVOID EYE INJURIES. USE CAREWHEN HAN-

DLINGTHE BLADE AFTER WELDING TO AVOID

BURNS.

1. Usingthe bladecutter,cut the bladeto the

required length (View A).

2. Usingthe bladegrinder, square-offthe blade

ends (View B). The blade ends need to be

perpendicularto the side ofthe blade. The

blade ends must be squareso there is minimal

gap betweenthe endswhen clampedfor weld-

ing.

3. Insert one end of the blade in the left clamp

(View C). Positionthe back edge of the blade

against the back of the left clamp. Then position

the end of the blade midwaybetweenthe left and

rightclamps. Tighten the leftclamp.

4. Insertthe other end ofthe blade inthe right

clamp. Positionthe back edgeof the blade

against the back of the right clamp. Then butt

the end ofthe bladeagainst the other end of

blade (the blade ends needto be in contact with

each other). Tightenthe rightclamp.

5. Setthe clamp pressureselector switch (clock-

wise rotation)to the setting requiredfor the width

of the blade beingwelded (see the table below).

9

NOTE: There will be some resistance when turning

the switch.

6. Press and hold the weld pushbutton. When the

pushbuttonis pushed,the rightclamp movesto

the leftto apply pressureto the blade ends. At

the sametime, sparkswill comefrom the blade

ends as they are beingwelded.

Blade Width

Clamp Pressure

(Inch)

SelectorSetting

1/8" to 1/4"

1

5/16" to 3/8"

2

1/2"

3

5/8"

4

3/4"

5

Loading...

Loading...