Service 20

2.6 Dynamic milk pump

The ultrasonic sensor installed in the milk path monitors the milk pump performance and flow of the milk. The voltage of the pump motor can be corrected by up to

±5 % as needed. Correcting the pump power output results in a constant milk foam quality and dispensing temperature.

When the milk pump is recalibrated (Service > Service routines > Factory calibration of components > Dynamic milk system) the control range is reset to „0“

and the pump can once again be corrected by ±5 %.

Important note:

The milk pump calibration can be run only when the milk system is clean, with no deposits or screening. Otherwise there is a risk that the machine software will

attempt to compensate for screening in the milk system by increasing the milk pump power level. In this case, the pressure in the milk system would rise and increase

the risk that milk could be forced into the steam boiler.

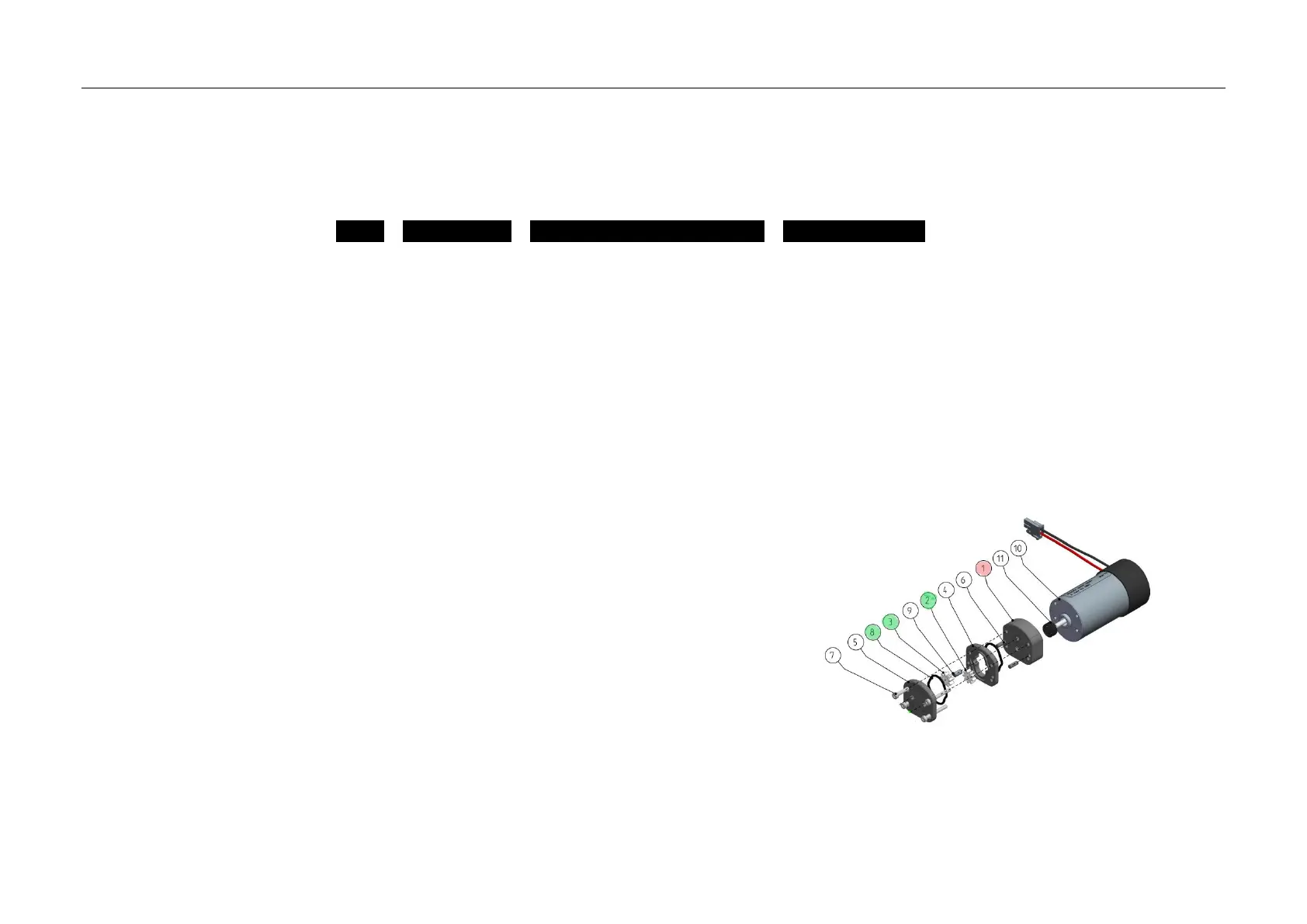

A spare parts kit is available for the milk pump with stainless steel pump head (manufacturer’s designation DGA04) to enable replacing the plastic gears and the seals

in the pump head.

Important note:

To prevent damage to the shaft seal, the base body of the pump head (Pos. 1) should not be disassembled.

Remove the 4 socket head screws (Pos. 7) and the cover (Pos. 5)

Remove the spacer plate (Pos. 4), taking care not to remove the base body (Pos. 1) from

the motor

Replace the two gears (Pos. 2+3) and the two seals (Pos. 8)

When installing the cover and the socket head screws, tighten the screws in a cross

pattern with a tightening torque of 0.9 to 1.1 Nm

Loading...

Loading...