Maintenance 36

4 Maintenance

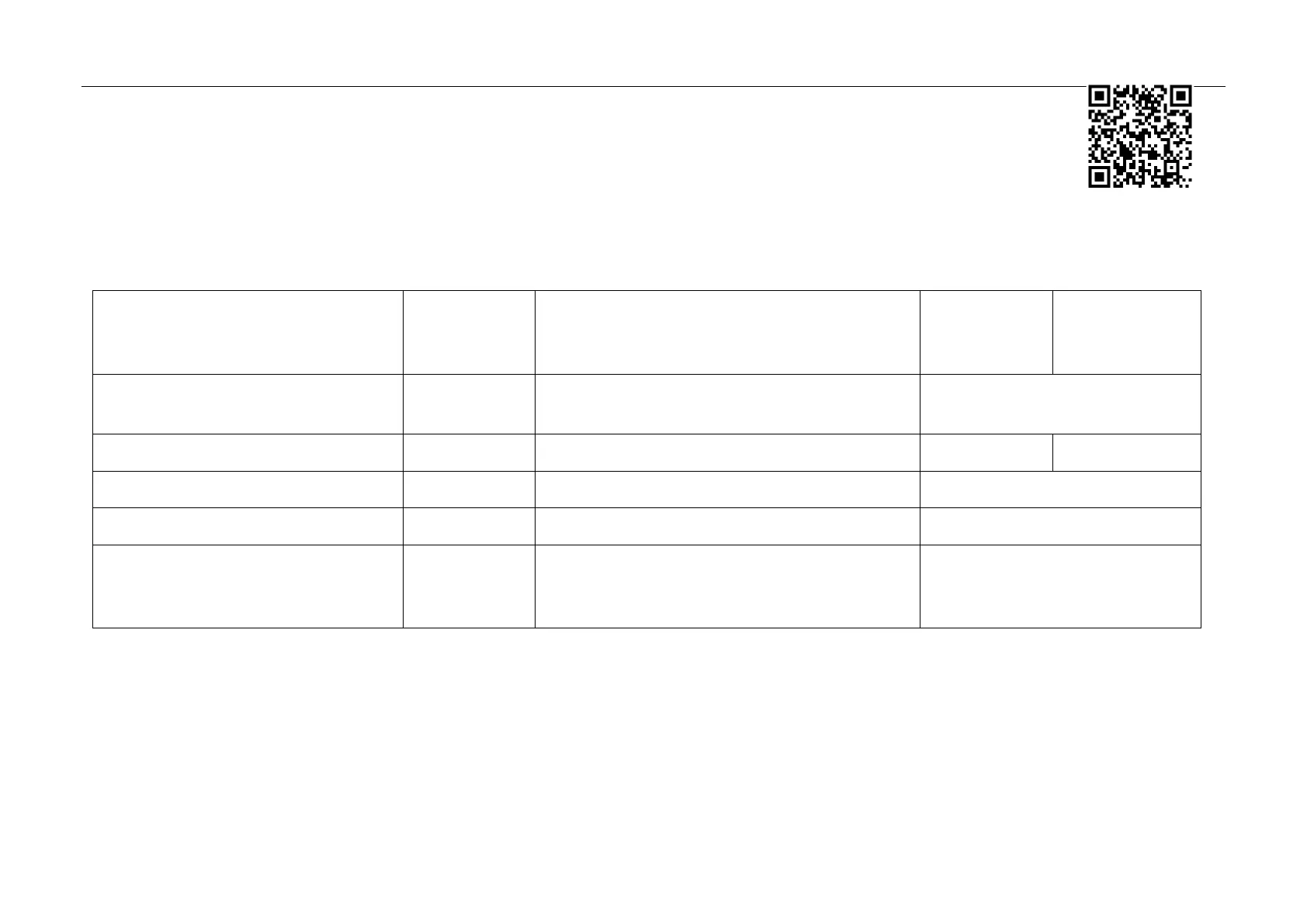

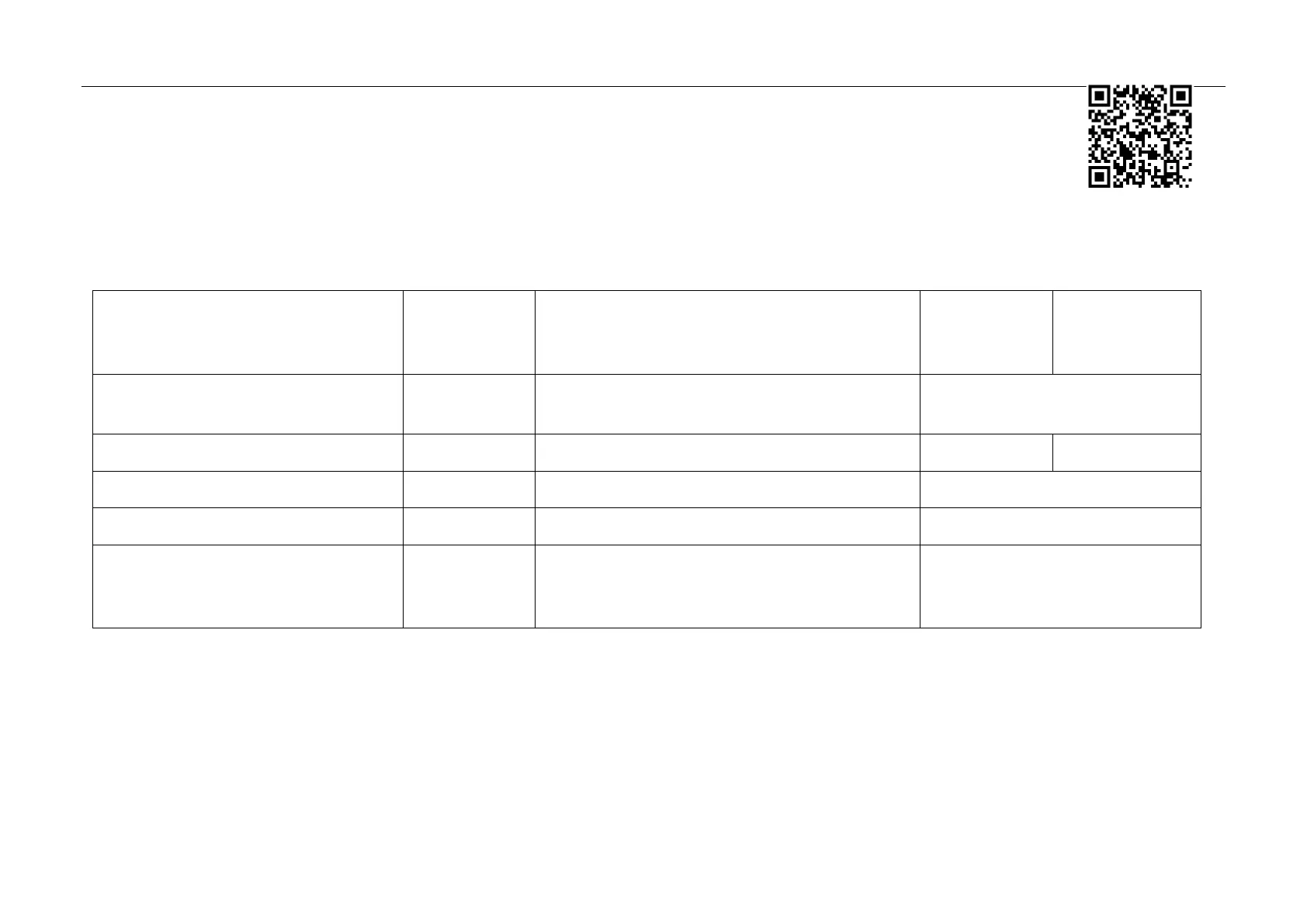

4.1 Maintenance concept – Overview of maintenance tasks

The following WMF maintenance concept based on time-/serving-dependent cycles, describes the minimum scope of maintenance activities as recommended by WMF.

Please also consider separate agreements from service contracts, as well as local conditions (which may make descaling necessary before the scheduled time, for

example).

Abbreviation

Maintenance

package

after 60,000 brewing cycles

33 2939 5000* standard

33 2836 8000* Fresh Filtered Coffee

Extended steam boiler and boiler inspection

Every year or after service life expires

Due date:

without water filter -> depends on hardness level setting

with water filter > 1 x annually

2 bottles WMF liquid descaling agent

33 7006 2869

1) The following options require additional installation as part of service maintenance 2:

Fresh Filtered Coffee: O-ring 33 1523 3100 and O-ring 33 0397 0000 at the tube connection

FFC or Chilled Coffee (machine equipped with a changeover valve): Valve body 33 4190 4000 and membrane 33 4190 3000

Dynamic Milk with FFC (machine equipped with two changeover valves): Valve body 33.4190.4100 and membrane 33 4190 3000

Dynamic Milk with Chilled Coffee (machine equipped with two changeover valves): Valve body 33 4190 4000 and membrane 33 4190 3000

An extended inspection of boiler and steam boiler is MANDATORY for technical safety reasons as part of service maintenance 2 (as for presto family)

* For details on the contents of the maintenance packages please see the following pages

Loading...

Loading...