3064458_201811

83

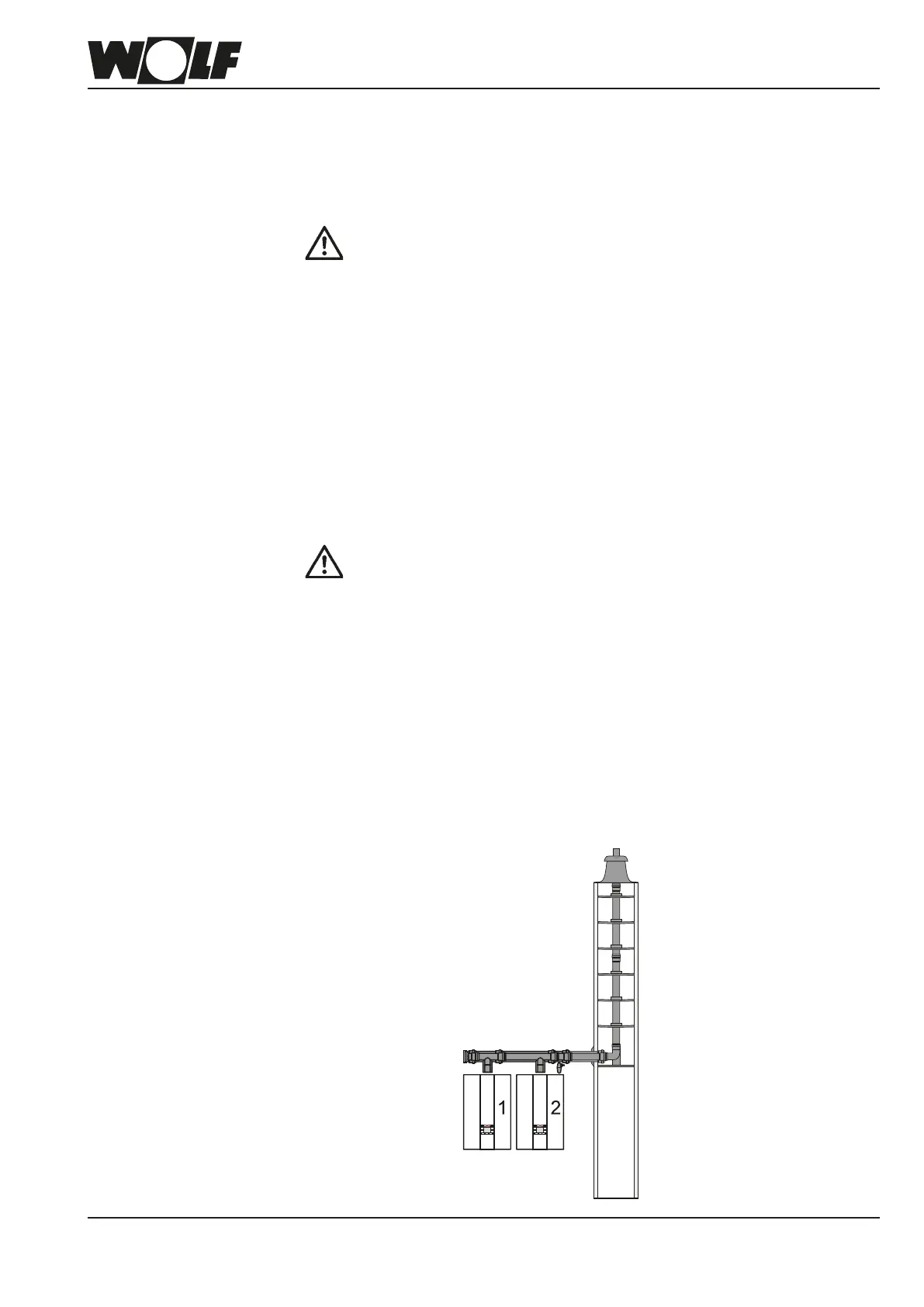

Tightness test on

connections to

adjacent appliances

As part of the annual boiler test, the cascade damper on overpressure boiler systems

must be tested for tightness, to ensure no CO

2

can escape into the boiler room

(risk of poisoning or asphyxiation).

The check must be carried out with the appliance closed.

We recommend proceeding as follows:

Tightness test on connections to adjacent appliances

- Select the mixer circuit via the right hand rotary selector. Press function key 3 and

use the rotary selector to select "Standby", then press to conrm. Repeat process

for "DHW".

- On the rst FGB, press and hold buttons 6 and 7 simultaneously for 5 seconds to

enable the emissions test mode for the boiler. è FGB- starts.

- Operate the rst FGB- for at least 5 minutes.

- On all other appliances, check the CO

2

content in the air connector:

- If the CO

2

value exceeds 0.2 % within 15 minutes, the leak must be found and

remedied.

- Subsequently close all test ports again. When doing so, ensure the caps are

seated rmly.

TestingtherstFGBfortightness

- Press reset button 4 to return the rst FGB into the previous operating mode è

emissions test mode is disabled. Press the operating mode button repeatedly until

the display shows "OFF". The boiler shuts down (standby mode).

- On the second FGB, press and hold buttons 6 and 7 simultaneously for 5 seconds

to enable the emissions test mode for the boiler. è FGB- starts.

- Operate the second FGB for at least 5 minutes.

- Check the CO

2

content in the air connector on the rst FGB.

- If the CO

2

value exceeds 0.2 % within 15 minutes, the leak must be found and

remedied.

- Subsequently close all test ports again. When doing so, ensure the caps are

seated rmly.

31.Technicalinformation,balancedue

Loading...

Loading...