3064458_201811

89

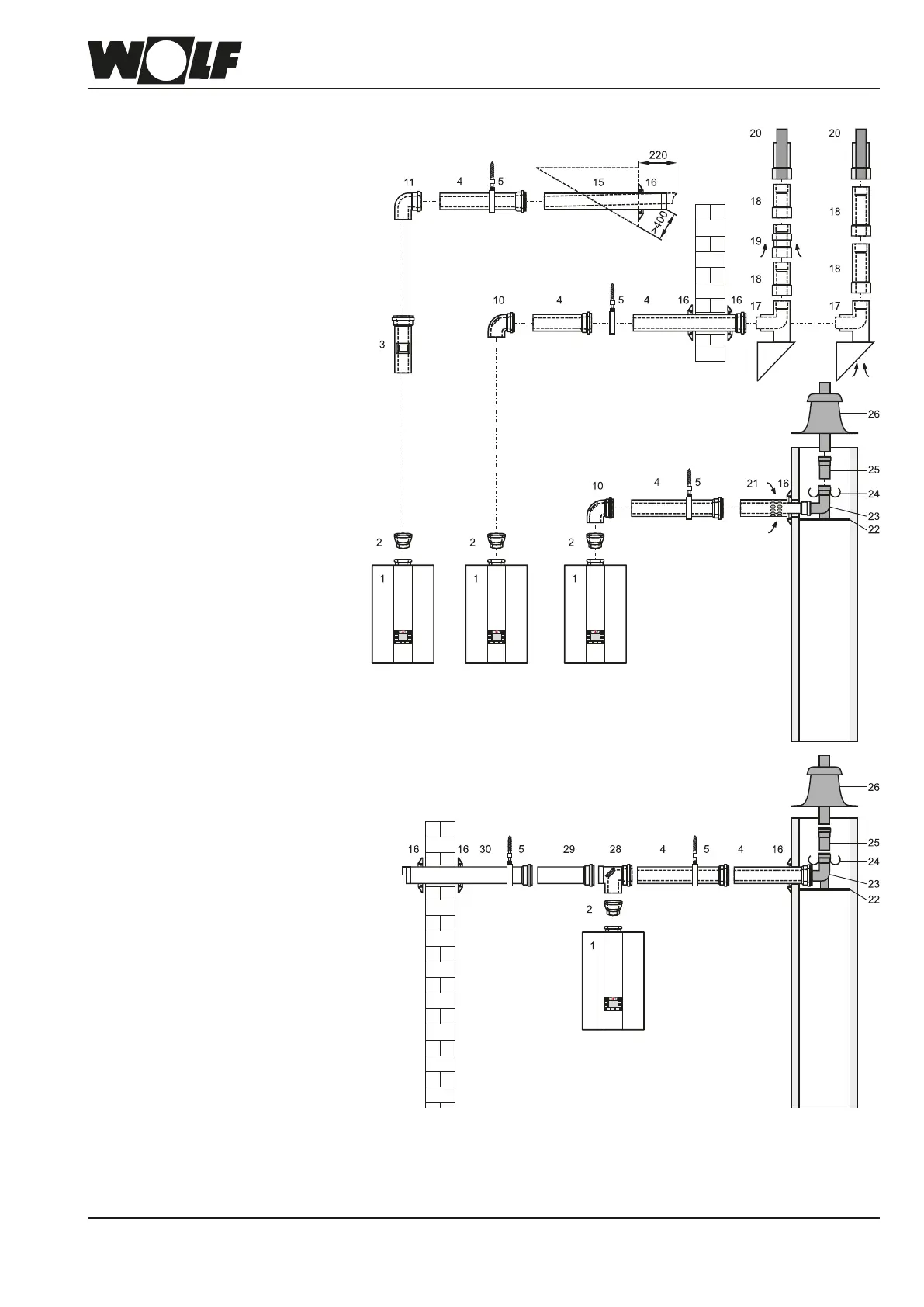

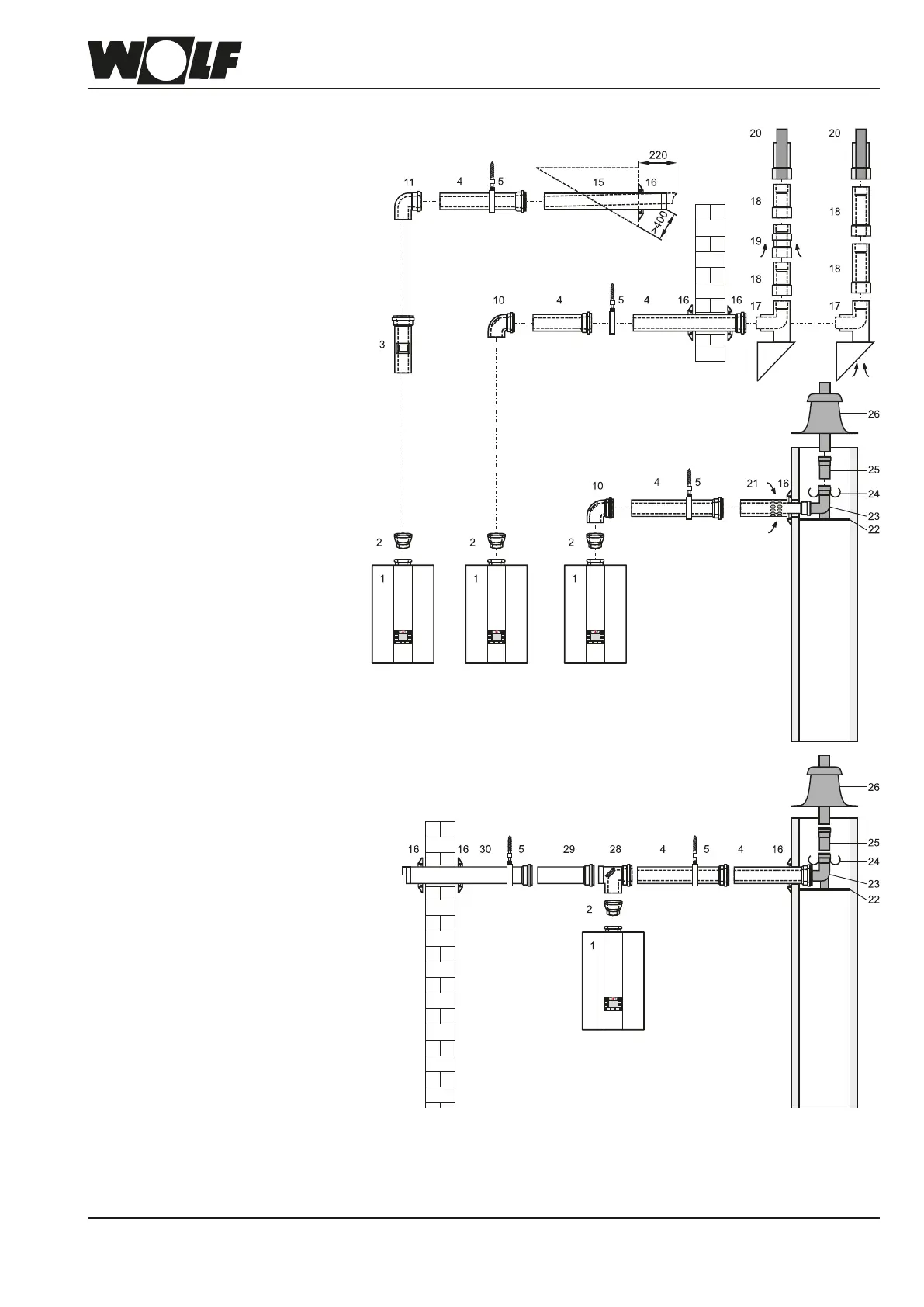

Concentricbalancedue,horizontalC13x,C83xandB33

andueonanexternalwallC53x(examples)DN80/125

Horizontal balanced ue routed

through pitched roof

Flue routed along

external wall

(only where required)

Recess Ø 90 mm in

chimney side. Install the

ue pipe airtight into the

chimney side.

C13x C53x B33

Dormer

1 Gas condensing boiler

2 Adaptor DN60/100

to DN80/125

3 Balanceduewith

inspection port DN80/125

(250 mm long)

4 Balancedue

DN80/125

500 mm

1000 mm

2000 mm

5 Spacer bracket

10 Inspection bend 87°

DN 80/125

11 Bend 87°

DN 80/125

15 Balancedue

horizontal,

with wind protector

16 Pipe collar

17 External wall panel 87°

DN80/125

with smooth air pipe end

18 Balancedue,externalwalls

DN80/125

19 Air inlet, external wall

DN80/125

20 Conc. outlet terminal

with clamp tting

21 Connection to a

uegaschimneyB33

Length 250 mm

with air aperture

22 Support rail

23 Support bend 87° DN80

24 Spacer

25 PPuepipeDN80

26 Shaft cover with

UV resistant terminal

28 Inspection tee

29 Air pipe Ø 125 mm

30 Air inlet pipe Ø 125 mm

Install the horizontal ue pipe with a slope of approx. 3° (6 cm/m) towards the boiler.

Route the horizontal air supply with a 3° slope towards the outside – provide the

air inlet with a wind protector; permissible wind pressure at the air inlet 90 Pa. The

burner will not start if the wind pressure is higher. After the support bend (23), the ue

can be routed in DN80 inside the shaft. A exible ue pipe DN83 can be connected

downstream of support bend (23).

C83x

31.Technicalinformation,balancedue

Loading...

Loading...