20

3064458_201811

Before commissioning, carry out a tightness

test on all hydraulic pipework:

Test pressure on the DHW water side max.

10 bar

Test pressure on the heating water side max.

4.5 bar

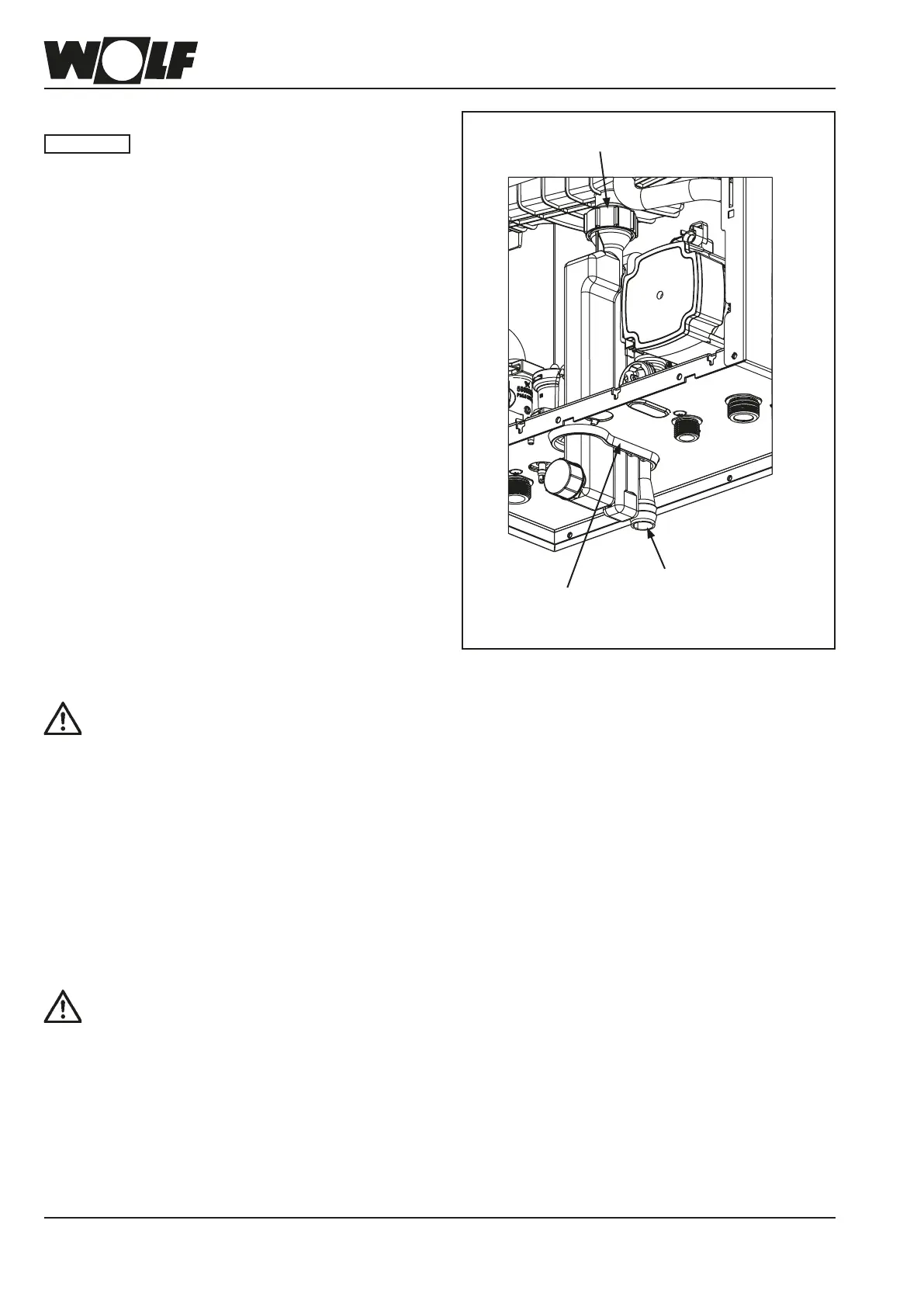

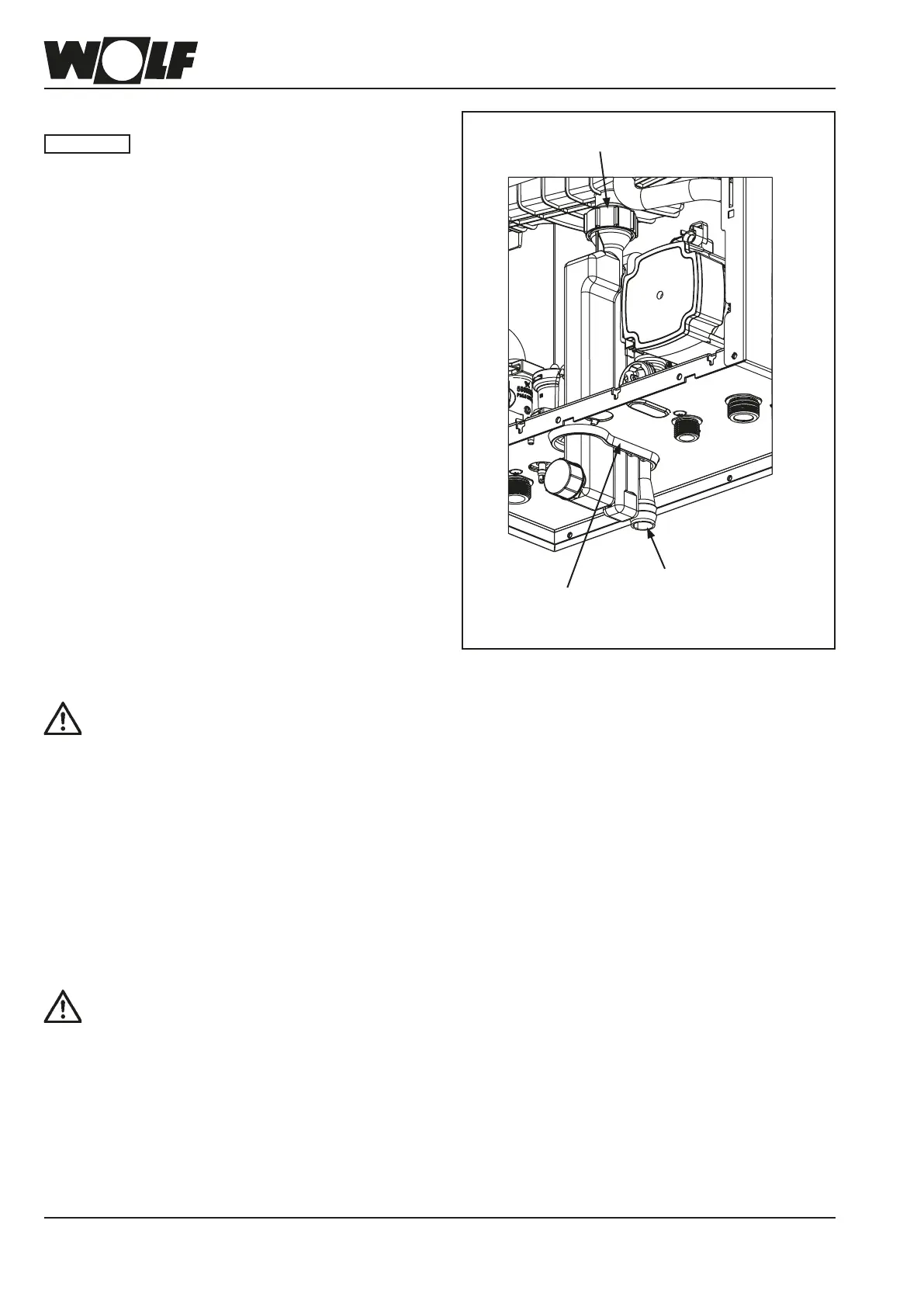

Fig: Trap

Note:

The condensate hose attached to the trap must not form a

loop or roll up, as this could lead to impaired operation.

12. Fitting the trap

Condensate drain connection

The trap must be tted before commissioning the appliance.

The trap included in the standard delivery must be tted

from underneath the appliance. Before installing, apply

silicone grease to the sealing collar. After insertion, secure

the screw tting of the trap to the connector and check the

connection is rm. Secure the sealing collar.

Ensure that the sealing collar seals the casing base.

The drain hose must be safely secured above the tundish

(trap).

If the condensate is directly routed to the sewer pipe, provide

a ventilation facility. This is to prevent retroactive effects from

the sewer pipe to the gas condensing boiler.

If installing a neutralising system (accessories), observe the

instructions supplied.

According to Code of Practice ATV-DVWK- A251, no

neutralising system is required for condensing boilers up to

200 kW.

If a neutralising system is used, the national regulations

regarding the disposal of residues from such systems apply.

The trap is lled via the ue; see chapter 18 "Filling the

heating system / trap".

Please note

Sealing collar

Tundish for drain hose

Condensate pan connector

Thetrapmustbelledwithwaterpriorto

commissioning. Operating the appliance with

an empty trap presents a risk of poisoning

orasphyxiationduetouegasesescaping.

Unscrewthetrap,removeandlluntilwater

runsoutofthedrainholeontheside.Ret

the trap and ensure the gasket seals tightly.

Loading...

Loading...