3064458_201811

93

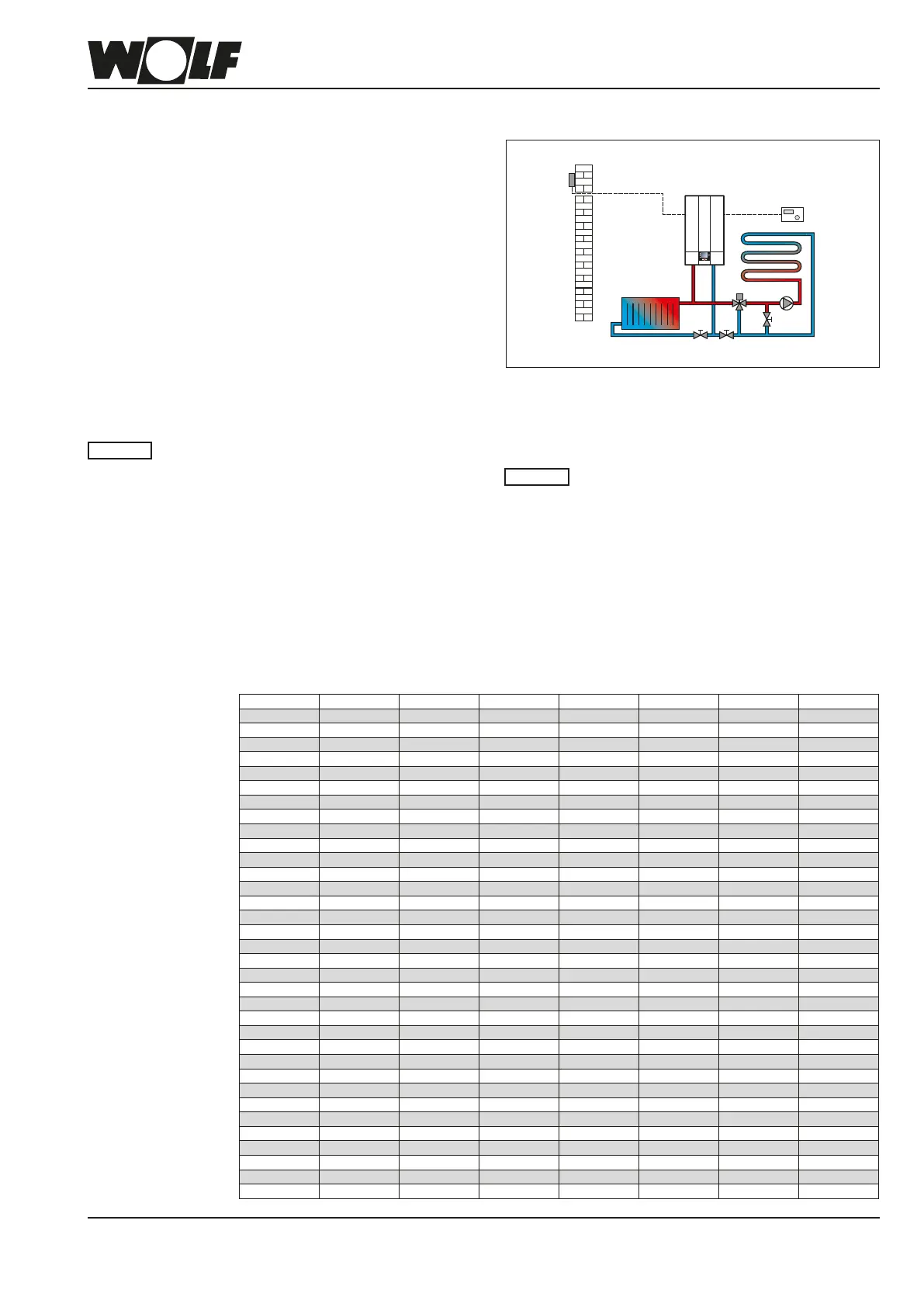

Underoorheatingsystem

For heating systems with plastic pipes, we recommend the

use of impermeable pipes to prevent the diffusion of oxygen

through the pipe walls.

When operating the condensing boiler in

conjunction with an underoor heating system,

we recommend sizing the usable volume of a

diaphragm expansion vessel 20 % larger than

recommended by DIN 4807-2. An diaphragm

expansion vessel of insufcient size results in

oxygen ingress into the heating system, causing

corrosion damage.

Please note

If pipes which are impermeable to oxygen are used, an

underoor heating system can be connected directly to a

heat source with up to 10 kW heating output, depending on

the system pressure drop.

Always install a temperature limiter for the underoor heating

system to protect the pipes from overheating.

The output of the integrated pump should be increased if

underoor heating is connected (parameters HG16 and

HG17). Recommendation HG16 Þ 75% and HG17 Þ 100%

For connection of an underoor heating system with an

output requirement in excess of approx. 10 kW, a 3-way mixer

(accessories MM) and an additional pump are required.

Install a regulating valve in the return; this can be used to

reduce the excessive head of the additional pump if required.

Ensure the system user cannot adjust any

regulating valves.

When using pipes that are diffusion-proof to

oxygen, it is necessary to provide system

separation by means of a heat exchanger.

Inhibitors may not be used.

If an additional heating circuit is operated in parallel to the

underoor heating system, it must be hydraulically matched

to the underoor heating system.

Please note

Fig: Underoor heating system (example

32.Designinformation,underoor

heating / DHW circulation

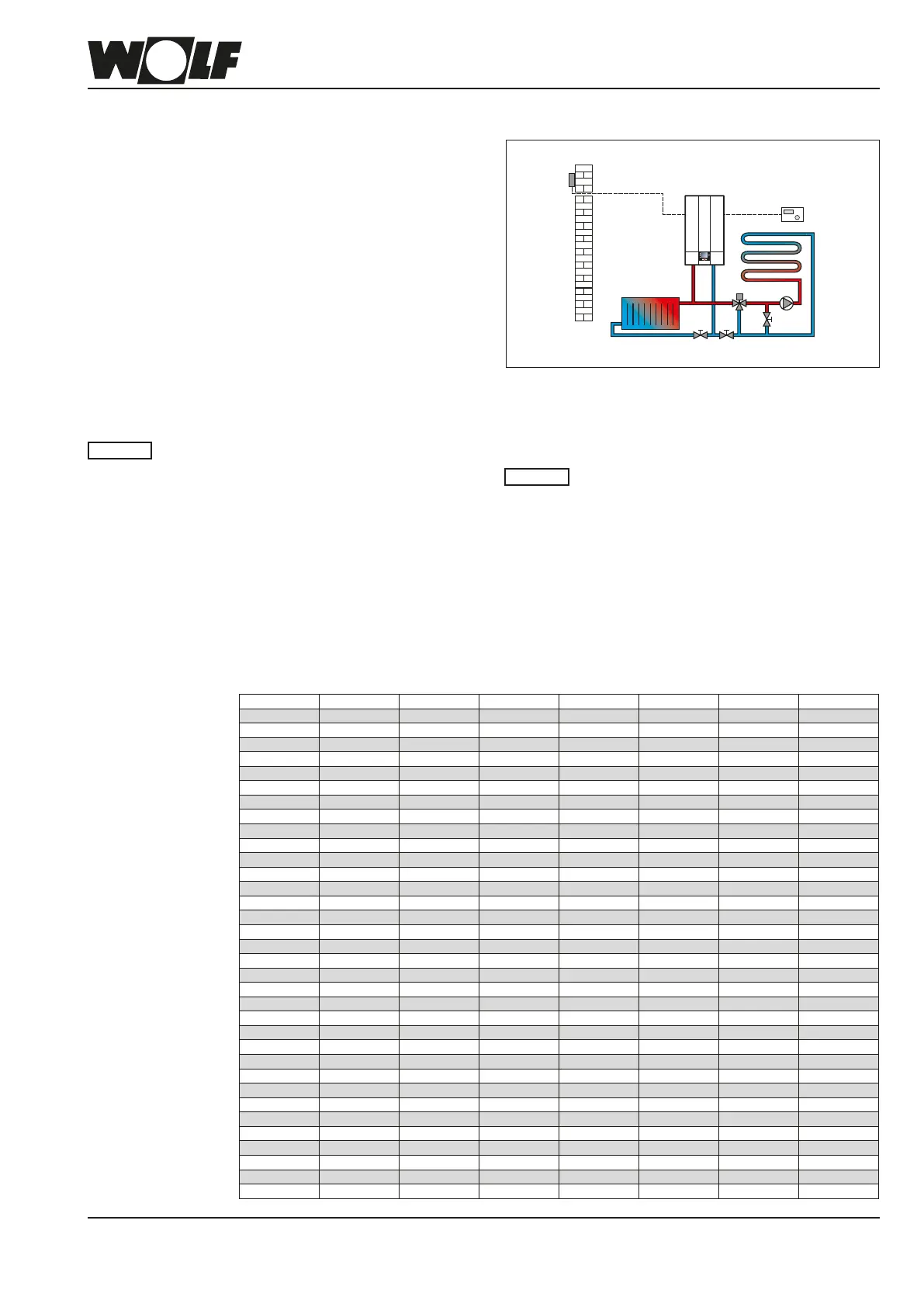

NTC

Sensor resistances

Flow temperature sensor, cylinder temperature sensor, DHW outlet temperature

sensor, outside temperature sensor, return temperature sensor, ue gas temperature

sensor

Temp. °C Resist.Ω Temp. °C Resist.Ω Temp. °C Resist.Ω Temp. °C Resist.Ω

-17 40810 17 7162 51 1733 85 535

-16 38560 18 6841 52 1669 86 519

-15 36447 19 6536 53 1608 87 503

-14 34463 20 6247 54 1549 88 487

-13 32599 21 5972 55 1493 89 472

-12 30846 22 5710 56 1438 90 458

-11 29198 23 5461 57 1387 91 444

-10 27648 24 5225 58 1337 92 431

-9 26189 25 5000 59 1289 93 418

-8 24816 26 4786 60 1244 94 406

-7 23523 27 4582 61 1200 95 393

-6 22305 28 4388 62 1158 96 382

-5 21157 29 4204 63 1117 97 371

-4 20075 30 4028 64 1078 98 360

-3 19054 31 3860 65 1041 99 349

-2 18091 32 3701 66 1005 100 339

-1 17183 33 3549 67 971 101 330

0 16325 34 3403 68 938 102 320

1 15515 35 3265 69 906 103 311

2 14750 36 3133 70 876 104 302

3 14027 37 3007 71 846 105 294

4 13344 38 2887 72 818 106 285

5 12697 39 2772 73 791 107 277

6 12086 40 2662 74 765 108 270

7 11508 41 2558 75 740 109 262

8 10961 42 2458 76 716 110 255

9 10442 43 2362 77 693 111 248

10 9952 44 2271 78 670 112 241

11 9487 45 2183 79 649 113 235

12 9046 46 2100 80 628 114 228

13 8629 47 2020 81 608 115 222

14 8233 48 1944 82 589 116 216

15 7857 49 1870 83 570 117 211

16 7501 50 1800 84 552 118 205

Loading...

Loading...