3064458_201811

55

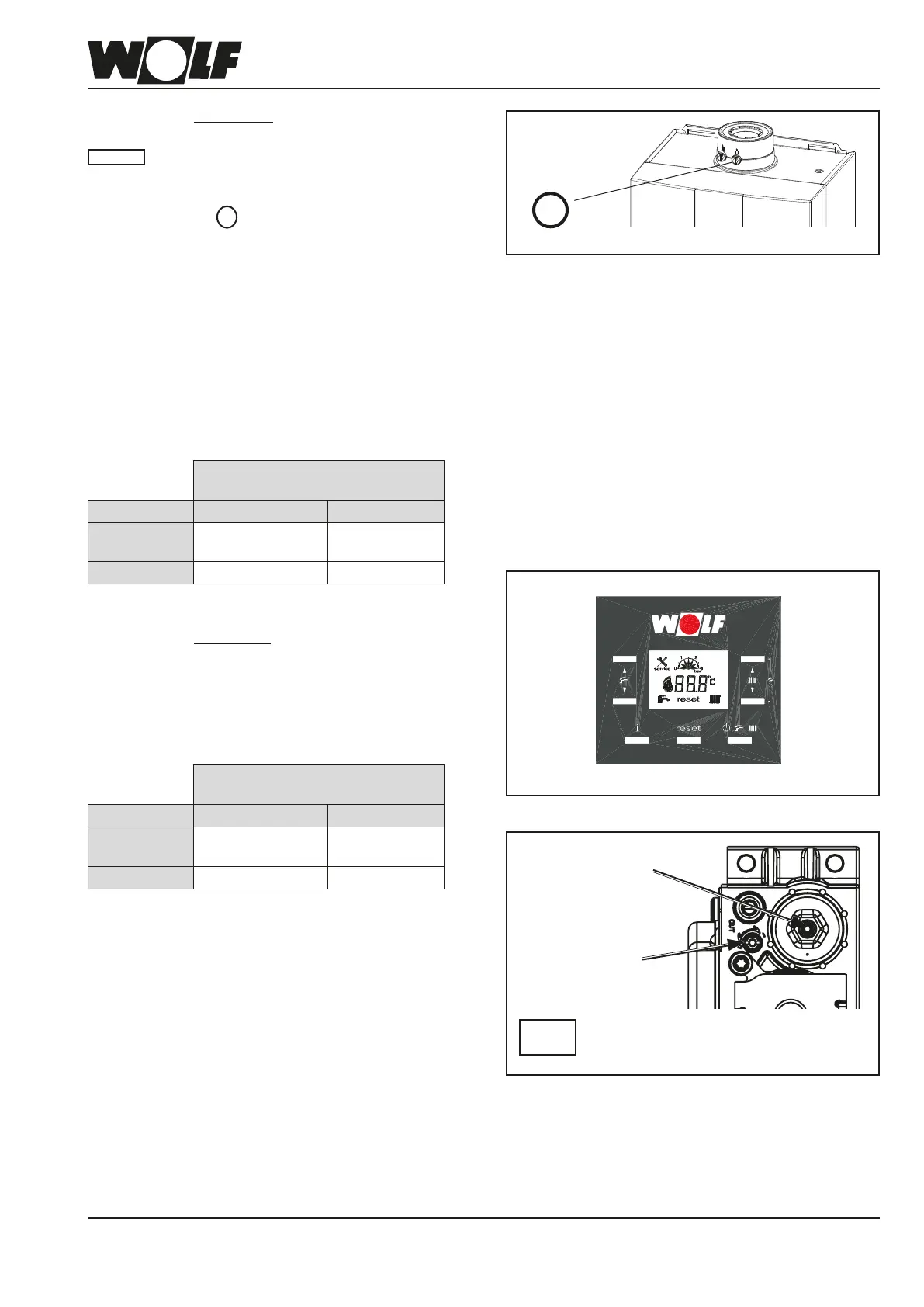

Fig: Gas combination valve

Fig: Test ports

CO

2

setting at lower

load (zero adjusting

screw)

CO

2

setting value

at upper load

23. Changing the gas type

1

2

4

6

7

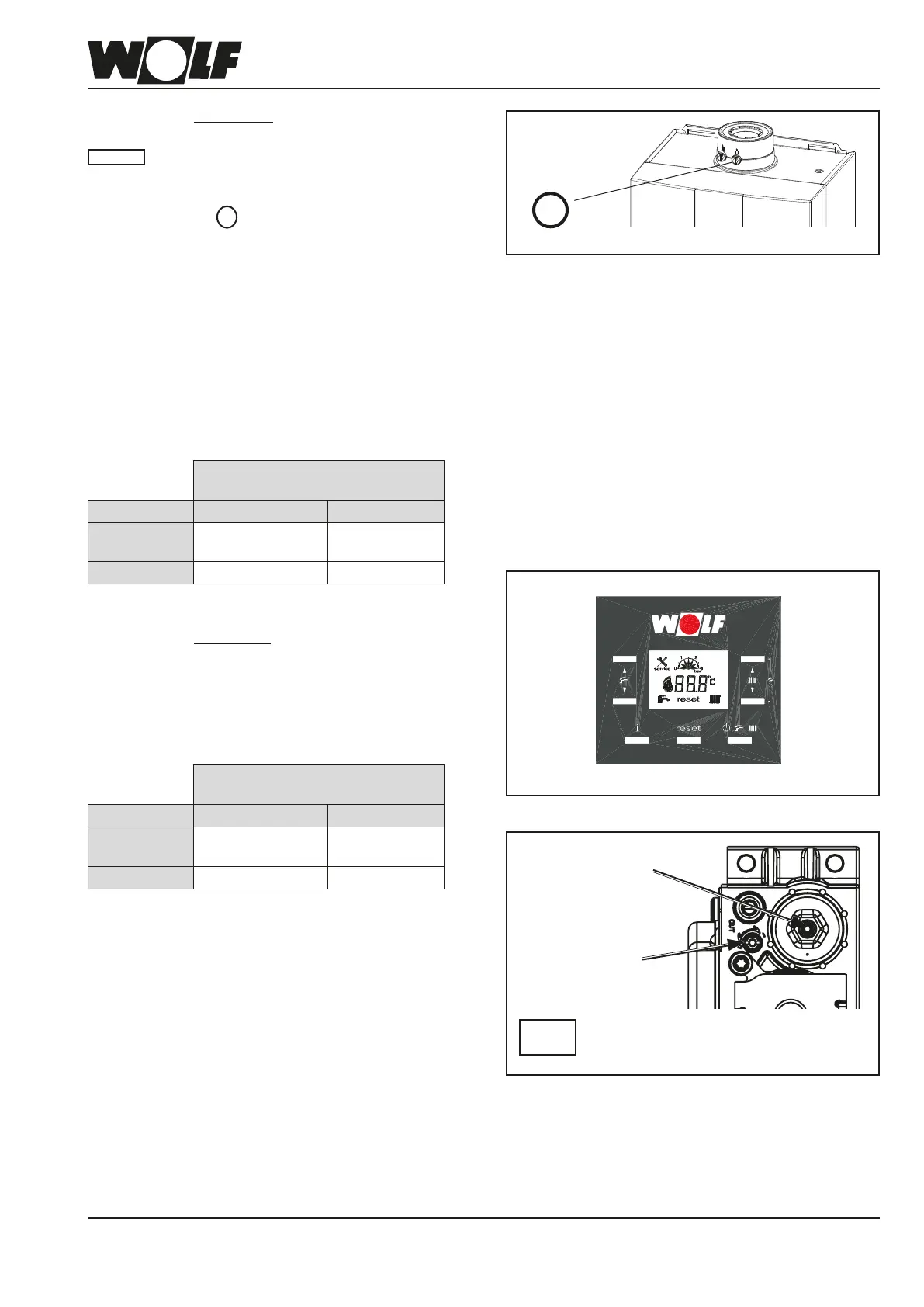

Fig: Control unit buttons

5

B

Flue gas test port

Do not remove the screws, otherwise it

will no longer be possible to adjust the gas

combination valve.

Please

note

CO

2

setting at upper load

When the test port is open, ue gas can

escape into the installation room. There is a

risk of asphyxiation.

1. Remove screw B from the right hand test port.

2. Open the gas ball valve.

3. Insert the test probe.

4. Activate emissions test mode (see control unit).

5. Approx. 20 s after the burner start, check the CO

2

content with the CO

2

tester. If required, adjust with

the zero point screw in accordance with the table.

- Clockwise rotation (-) – lower CO

2

content.

- Anti-clockwise rotation (+) – higher CO

2

content.

FGB / FGB-K

appliance open at upper load

Gas type CO

2

in % O

2

in %

Natural gas

E/H/LL

9.1 % ± 0.2 % 4.5 ± 0.3 %

LPG P 10.2 % ± 0.2 % 5.4 ± 0.3 %

CO

2

setting at lower load

1. Activate emissions test mode and

press DHW key - (2)

- Clockwise rotation – higher CO

2

content.

- Anti-clockwise rotation – lower CO

2

content.

FGB / FGB-K

appliance open at lower load

Gas type CO

2

in % O

2

in %

Natural gas

E/H/LL

8.9 % ± 0.2 % 5.0 ± 0.3 %

LPG P 9.8 % ± 0.2 % 6.0 ± 0.3 %

2. After completing the work, ret the casing cover

and check the CO

2

values with the appliance

closed.

The boiler is correctly adjusted when the CO

2

values correspond to those in table

"25. Testing the combustion parameters".

3. Optionally, a change to the upper load range can be

made by pressing the hot water button (1).

4. Disable emissions test mode (press key 4). After

the test has been completed, switch the appliance

off, remove the test probe and close the test port.

Ensure the screws/gasket are tight/seated rmly.

Please note

Loading...

Loading...