96

3064458_201811

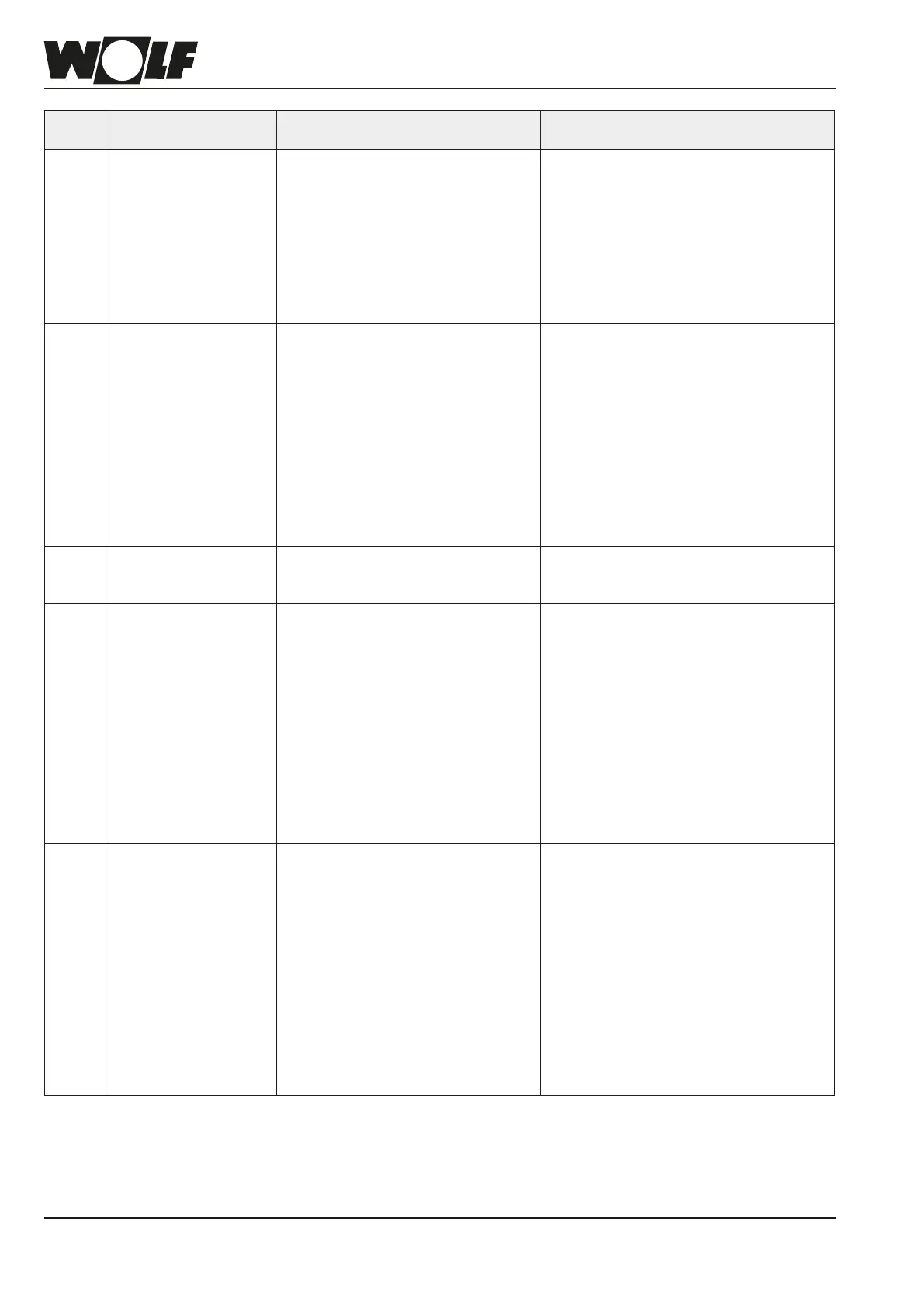

34. Troubleshooting

Fault

code

Fault Possible causes Remedy

01 HLSC excess temp. The high limit safety cut-out (thermostat)

has responded.

The temperature at the heat exchanger

cover has exceeded 110 °C.

Combustion chamber contaminated.

High limit safety cut-out:

- Check cables and plugs.

- If electrical connection OK and

no function: Replace HLSC.

Combustion chamber:

- If combustion chamber is contaminated,

clean or replace combustion chamber.

Check heating circuit pump.

Vent the system.

Press reset button.

02 TL excess temp. One of the temperature sensors in the

ow or return has exceeded the tem-

perature limiter limit (105 °C).

System pressure

Air in heating circuit

Temperature limiter

Pump

Check system pressure.

Vent heating circuit.

Temperature limiter (flow / return)

- Check cables and plugs.

- If OK and no function, replace flow tem-

perature sensor or return temperature

sensor.

Pump:

- Check if pump is running.

- If not, check cables and plugs.

- If electrical connection OK and

no function: Replace the pump.

Press reset button.

03 dt ow-return drift Sensor test function failed, temperature

difference between ow and return sen-

sor > 5 °C.

Check sensors, replace if necessary

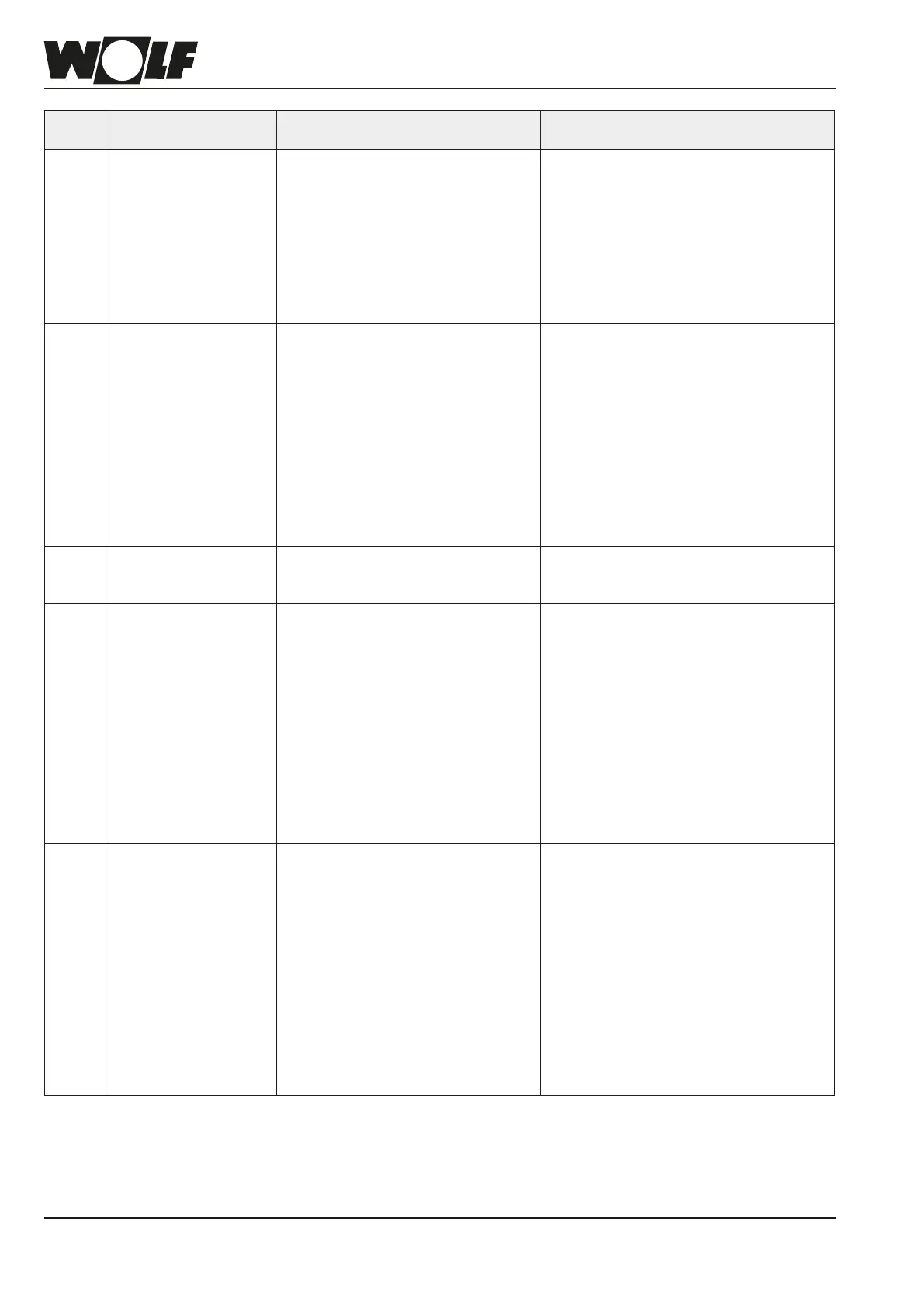

04 No ame formation When the burner starts, no ame forms

by the end of safety time.

Monitoring electrode faulty

Ignition electrode faulty, ignition trans-

former faulty.

Gas supply

Gas condensing boiler contaminated

Gas supply:

- Check the gas train (gas valve open?).

Ionisation electrode:

- Check the position and condition of the

electrode, adjust or replace if necessary.

Ignition electrode:

- Check the position of the ignition electrode

and adjust if necessary. Check the ignition

transformer and wiring.

Gas valve:

- Check that the gas valve opens, if not,

check cables and plugs and repeat test.

- If faulty, replace the gas valve. Press reset

button.

05 Flame failure Flame failure during ame stabilisation

after ame detection

Monitoring electrode faulty

Flue path blocked

Condensate drain blocked

Gas type setting

Gas pressure

Flue gas recirculation

(ue gas in the ventilation air)

Gas condensing boiler contaminated

Gas type setting:

- Check gas type setting on the gas valve

and in H12.

Gas pressure:

- Check the gas supply pressure (flow

pressure). Monitoring electrode:

- Check the condition of the electrode; clean

or replace if necessary.

- Adjust gap and position or replace if

necessary.

Flue gas recirculation:

- Check flue path inside and outside the

appliance (leaking, blocked).

Press reset.

Loading...

Loading...