SERVICING AND SPARES

6 720 806 548 (2013/02)34

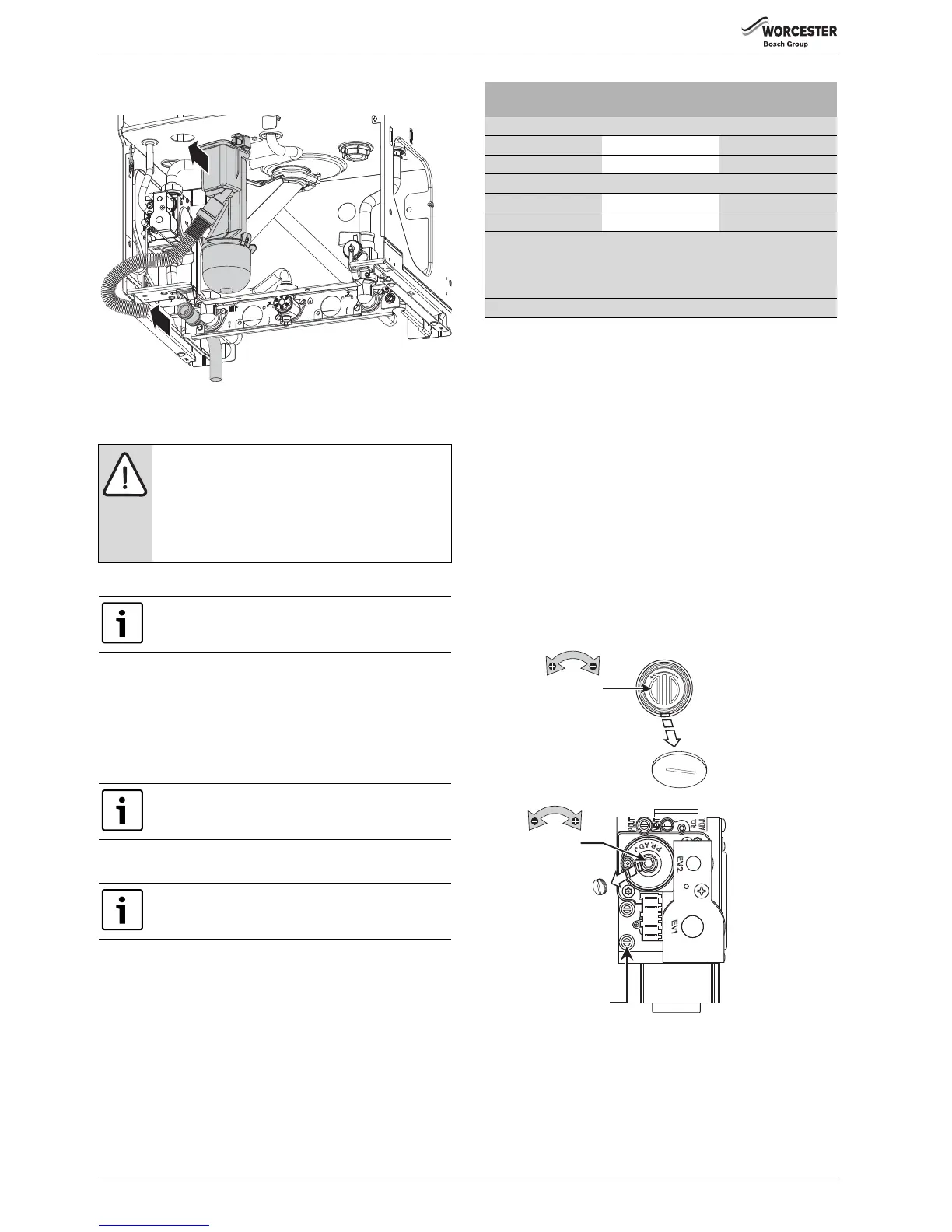

▶ Fill the condensate trap with approximately 250 millilitres of water

and refit in reverse order

Fig. 55 Siphon removal

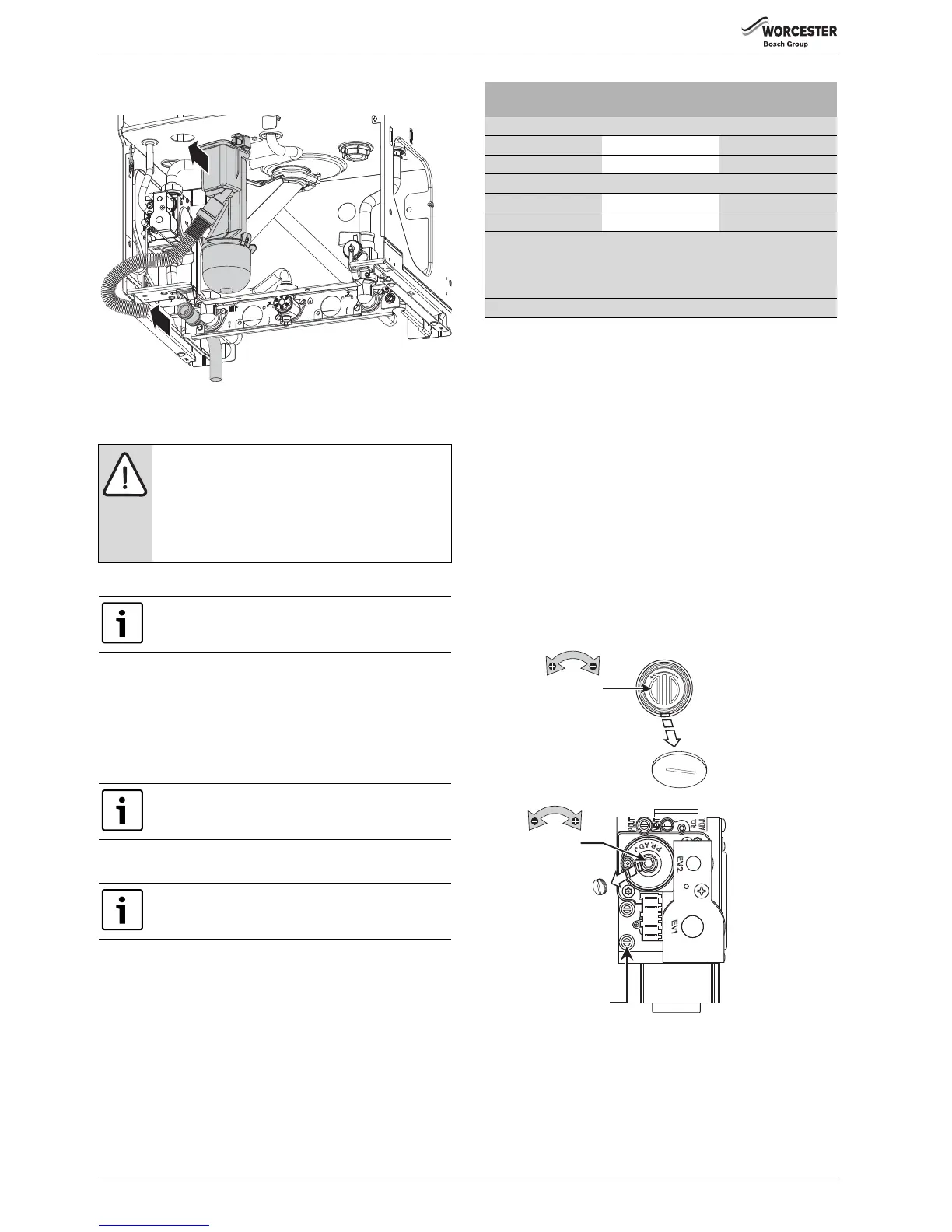

6.2 SETTING THE AIR/GAS RATIO

SETTING THE CO

2

1. Connect manometer to inlet test point on the gas valve.

▶To adjust the CO

2

it will be necessary to first operate the boiler at

maximum output.

▶ Press and hold down the performance test button for 10 seconds until

illuminated.

2. Turn central heating control to maximum; the boiler will then go to

maximum output.

3. Using a flat blade screwdriver set the CO

2

via the max adjuster

referring to the table below.

▶ Check CO is less than 200 ppm.

▶ Measure the gas inlet pressure at the gas valve test point; it should be

a maximum of 2.5mbar less than the pressure at the meter for natural

gas and a maximum of 4mbar less than the pressure at the regulator

for LPG.

4. Set the central heating control to minimum. This will make the boiler

go to minimum power.

5. Measure the CO

2

; it should now be at the figure for minimum output.

▶ If not, use a 4mm Allen key to adjust the min adjustment on the gas

valve until correct.

▶ Return to maximum and re-check the CO

2

.

▶ If correct press and hold down the performance test button for two

seconds; the button will cease to be illuminated and the blue power

indicator will be permanently illuminated.

▶ Remove manometer and re-seal inlet pressure point on gas valve.

▶ Fit new plastic sealing cover onto the max adjuster.

▶ Replace the brass screw over the min adjuster on the valve.

▶ Re-assemble and refit boiler case.

Fig. 56 Setting the Air/Gas ratio

NOTICE: Air/Gas ratio

▶ The setting of the gas ratio must be carried out by a

competent person.

Setting the air/gas ratio must not be attempted unless

the person carrying out the operation is equipped

with a combustion analyser conforming to BS 7927

and is competent in its use.

When running in the performance test mode ensure the

motorised valve(s) are open to avoid the boiler cycling

during the commissioning operation

The control will resume normal operation after 15

minutes or if the performance test button is pressed for

over a second.

CO

2

should be measured 10 minutes after firing the

appliance.

Gas type

CO

2

setting

maximum

CO

2

setting

minimum

Greenstar 30CDi

Natural gas 9.6% ±0.4 9.0% ±0.4

LPG 11.5% ±0.4 10.5% ±0.4

Greenstar 40CDi

Natural gas 9.7% ±0.4 9.1% ±0.4

LPG 11.5% ±0.4 10.5% ±0.4

NOTE: When checking an existing appliance the tolerance is ± 0.4%.

If checking after cleaning or component replacement or for adjustment

when the reading is outside the tolerance given above, then the

tolerance is ± 0.2%

CO - less than 200 ppm (0.002 ratio)

Inlet pressure

test point

Min

adjust

4mm

Max

adjust

6720647361-48.1Wo

Loading...

Loading...