Commissioning

Greenstar Danesmoor Utility

ErP

and Utility System

ErP

- 6 720 813 286 (2014/09) 37

Fig. 62

▶ Repeat the procedure at least 3 times or until a steady stream of oil,

without air, runs from the bleed port, then lock the bleed port.

▶ Switch off the boiler.

▶ Remove the oil pump filter, clean with kerosene and refit.

The internal filter is accessed by removing the oil pump cover.

▶ Safely dispose of the container/discharge.

▶ Fit a suitable pressure gauge to port (A) on the oil pump.

▶ Adjust the air shutter (L) and pump pressure (B) as shown in the

table 8 on page 38. The burner should ignite following a pre-ignition

period of approximately 15 seconds.

▶ If changing the burner output, check the position of the air damper

disc is correct to the output as shown in the table below.

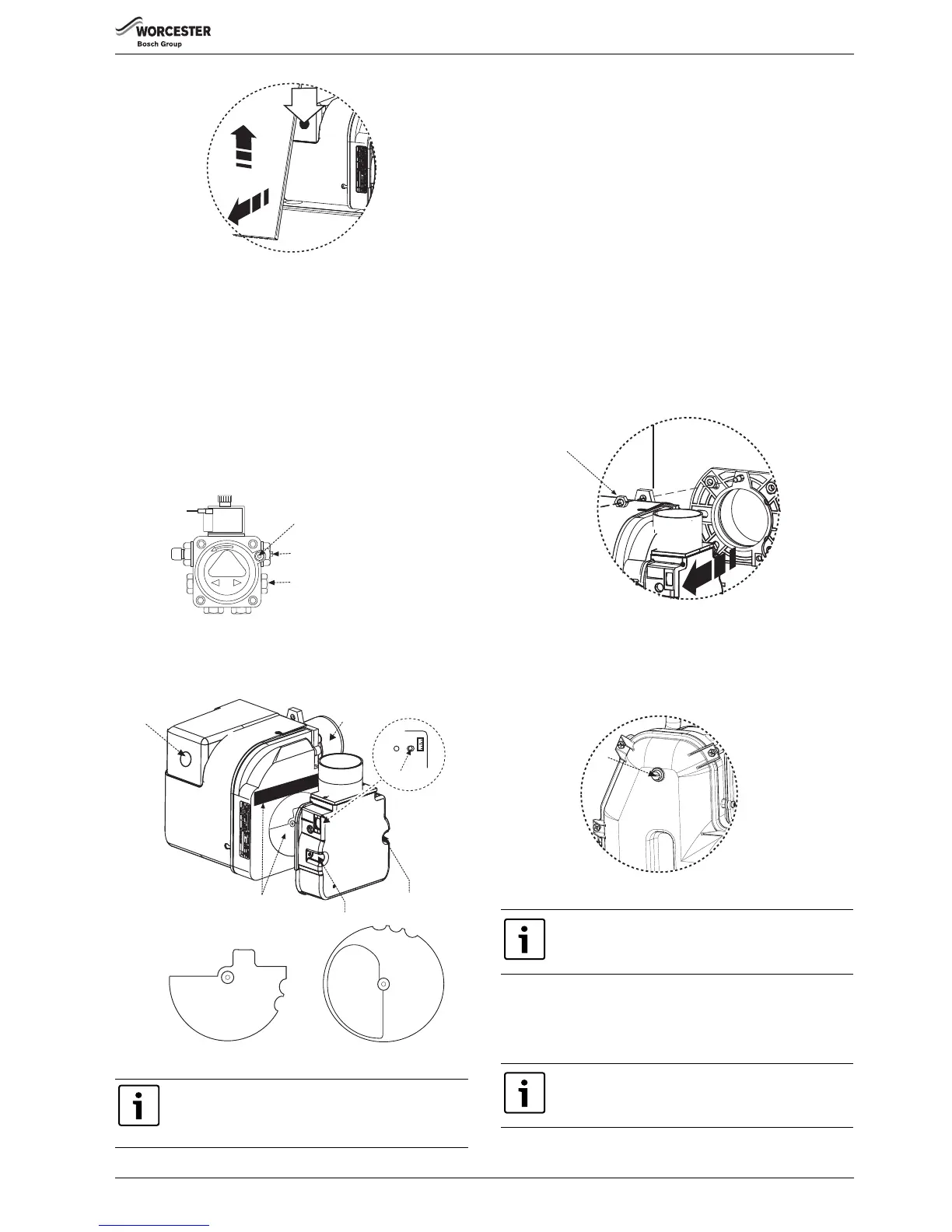

Fig. 63

[A] Bleed and pressure gauge port

[B] Pressure adjustment

[C] Vacuum gauge port

Fig. 64

Boiler lock out indicator on:

If the burner fails to establish a normal firing pattern or flame failure

occurs the flame monitoring photocell mounted in the burner body will

alert the burner control box to shut the burner down and provide a safe

lockout state indicated by the illumination of the lockout indicator (D).

▶ Wait 2 minutes then press the lockout reset button D (see figure 67)

to initiate another start sequence.

▶ Repeat procedure until a flame is established.

1. Start and run for 3 minutes then switch off.

▶ Check for after-spurting from the nozzle, indicated by oil saturation

on the combustion head (G figure 67).

If after-spurting occurs:

▶ Release the burner retainer nut (F).

▶ Remove the burner, combustion head (G). and electrodes, hold the

burner vertical to unscrew the nozzle and fill the nozzle holder with

kerosene.

▶ Refit nozzle, electrodes, combustion head (G) and the burner.

▶ Restart and run for 3 minute intervals until after-spurting stops.

Fig. 65

2. Start and run for 20 minutes

▶ Remove sampling point plug (K) to check the smoke reading is

between 0-1. If the smoke level is above 1, check the combustion

settings are correct and the oil nozzle is in good condition.

Fig. 66

▶Check the CO

2

levels and adjust the air shutter (L) setting according

to the table opposite.

▶ Check the flue gas temperature is close to the values shown in the

table 8 on page 38.

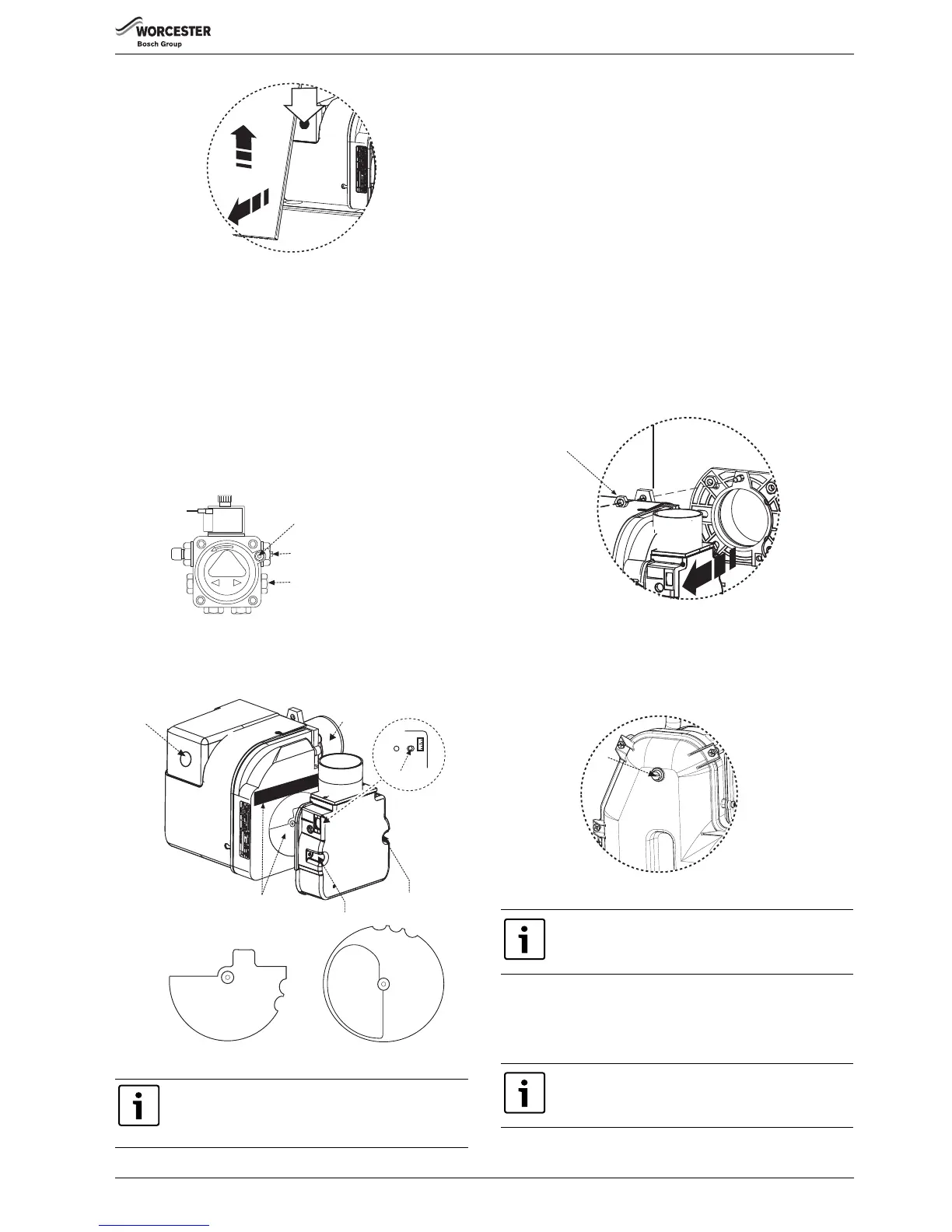

Adjust position of air damper discs to suit burner output

(see table 8 on page 38), located as above. Access by

removing the two star screws (SC) to release the air inlet

manifold.

Loading...

Loading...