Service and Spares

Greenstar Danesmoor Utility

ErP

and Utility System

ErP

- 6 720 813 286 (2014/09)44

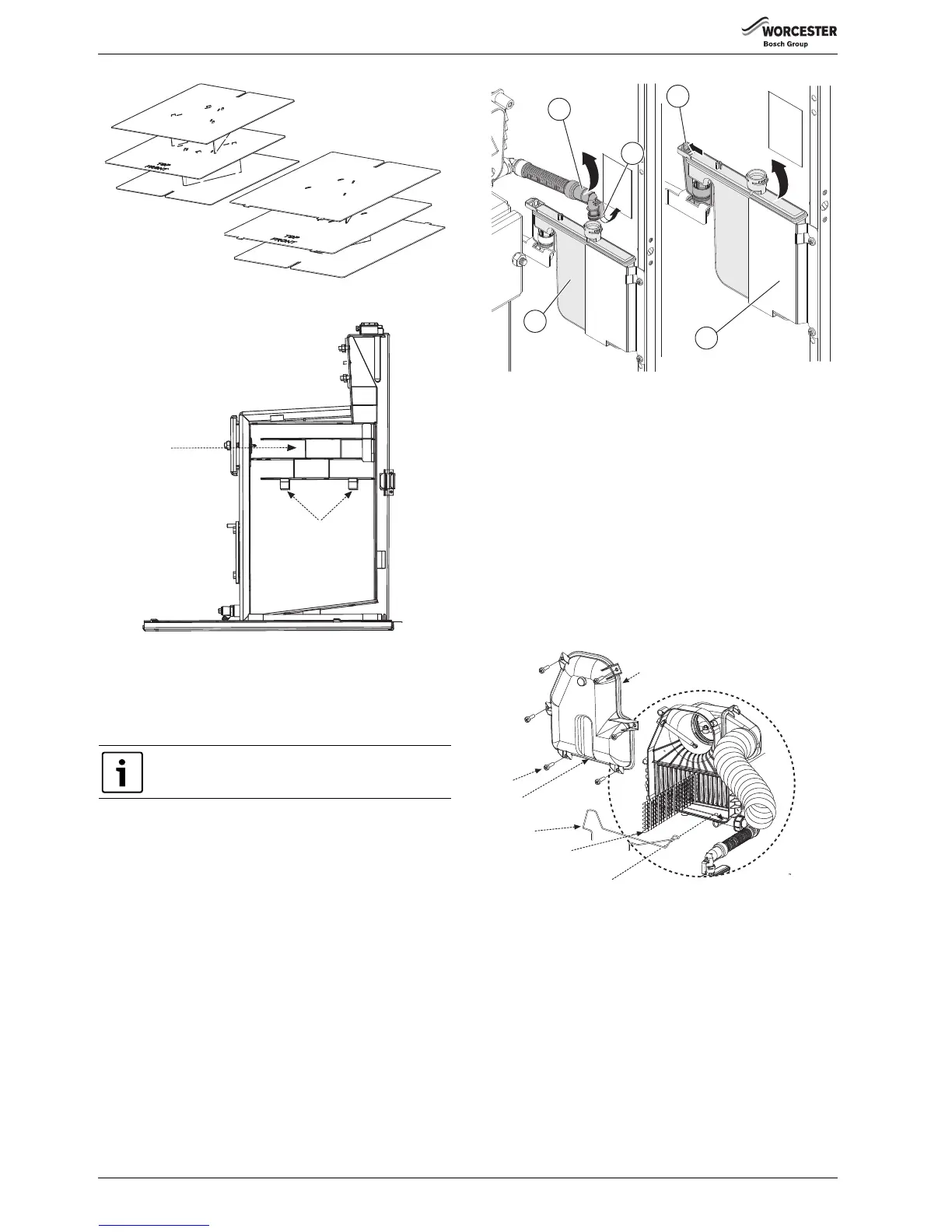

Fig. 80 Baffle detail

Fig. 81 Baffle positioning

Oil supply system and tank

▶ The oil pipeline, filters, fire valve and tank should be inspected and

maintained in accordance with OFTEC regulations.

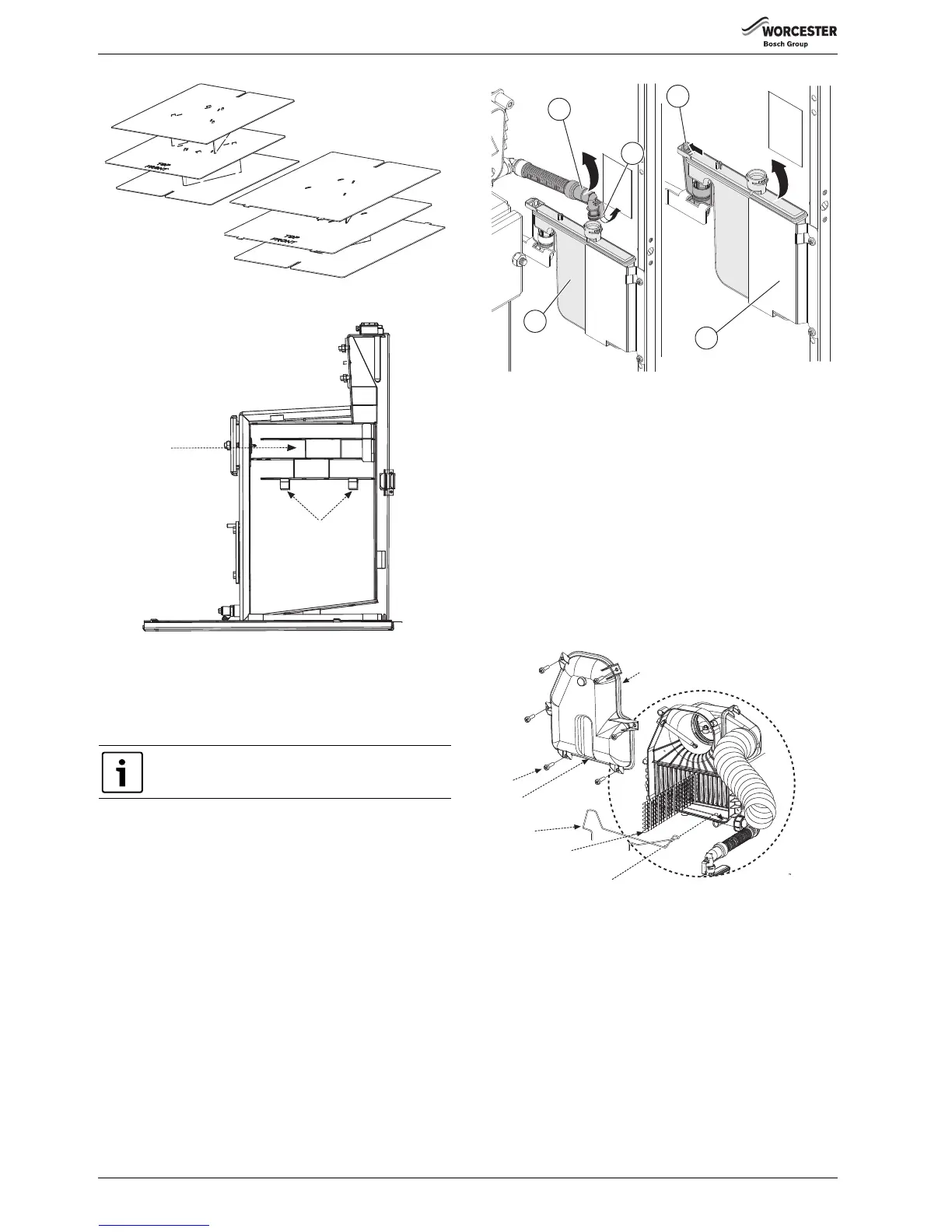

Cleaning the boiler, manifold access:

▶ Release screws (A) to remove the flue manifold access cover (B) and

clear any debris.

▶ Check the flue system and clean if necessary.

▶ Remove the baffle retainer (C) and baffles (D) from the secondary

heat exchanger.

▶ Check and clean the secondary heat exchanger surfaces.

▶ Check the condensate route (E) is clear.

▶ The condensate trap (F) should be removed and checked for debris.

▶ Release the pipe locking tab (G) and disconnect the flexible pipe (H)

from the top of the trap and move the flexible pipe up away from the

trap.

▶ Release the trap locking tab (I) and move the trap up and back to

remove from its mountings.

▶ Clean the trap by flushing with water.

▶ Check the O ring seals and replace if necessary, grease the seals with

a solvent free grease.

▶ Refit the trap making sure that the locking tabs are locked in place.

Fig. 82 Condensate trap removal

[F] Condensate trap

[G] Pipe locking tab

[H] Flexible pipe

[I] Trap locking tab

[K] Trap retaining bracket

▶ Pour 500ml of water into drain (E) to refill the condensate trap.

Ensure that the trap is discharging correctly and that all condensate

pipework joints are water tight.

▶ Clean the secondary heat exchanger baffles (D) if necessary and refit

correctly.

▶ Refit the baffle retainer (C).

▶ Check the seal on the manifold access cover (J) and replace if

necessary.

▶ Refit the flue manifold access cover (B) and secure with screws (A).

Fig. 83 Heat exchanger baffles

Do not use wire brushes and cleaning agents to clean the

stainless steel secondary heat exchanger components.

Loading...

Loading...