31

(b)

Remove the three remaining screws holding the front cover

plate in position and withdraw the cover to expose the fan

impeller.

(c) Clean both sides of the fan impeller and remove any debris

from the burner housing.

(d) Check that the impeller rotates freely.

(e) Clean the air inlet passage and check that the adjustment

mechanism, operates freely.

(f) Reassemble the components.

Electro Oil Inter B11 Burner

(a)

Remove the acoustic fan inlet cover.

(b) Remove the five screws holding the fan cowl in position and

remove the cowl noting how the fan control flap is positioned.

(c) Check that the air control flap pivots freely and ensure that

the air path to the burner head is clear.

(d) Clean both sides of the fan impeller and remove any debris

from the burner housing.

(e) Check that the impeller rotates freely.

(f) Reassemble the components.

Electro Oil Sterling Burner

(a)

Remove the air adjustment cover.

(b) Separate the main body of the burner from the burner front

by removing the M5 allen screw (located beneath the air

adjustment screw), using a 4mm allen key.

Check the condition of the gasket between these two parts and

replace if necessary.

(c) Note the position of the air damper adjustment and check the

air damper moves freely.

(d) Clean both sides of the fan impeller and remove any debris

from the burner housing.

(e) Check that the impeller rotates freely.

(f) Reassemble the components.

3. Remove the combustion head and thoroughly clean any

deposits.

4. Inspection of Mechanical Shut-off Valve.

(a)

Remove the nozzle

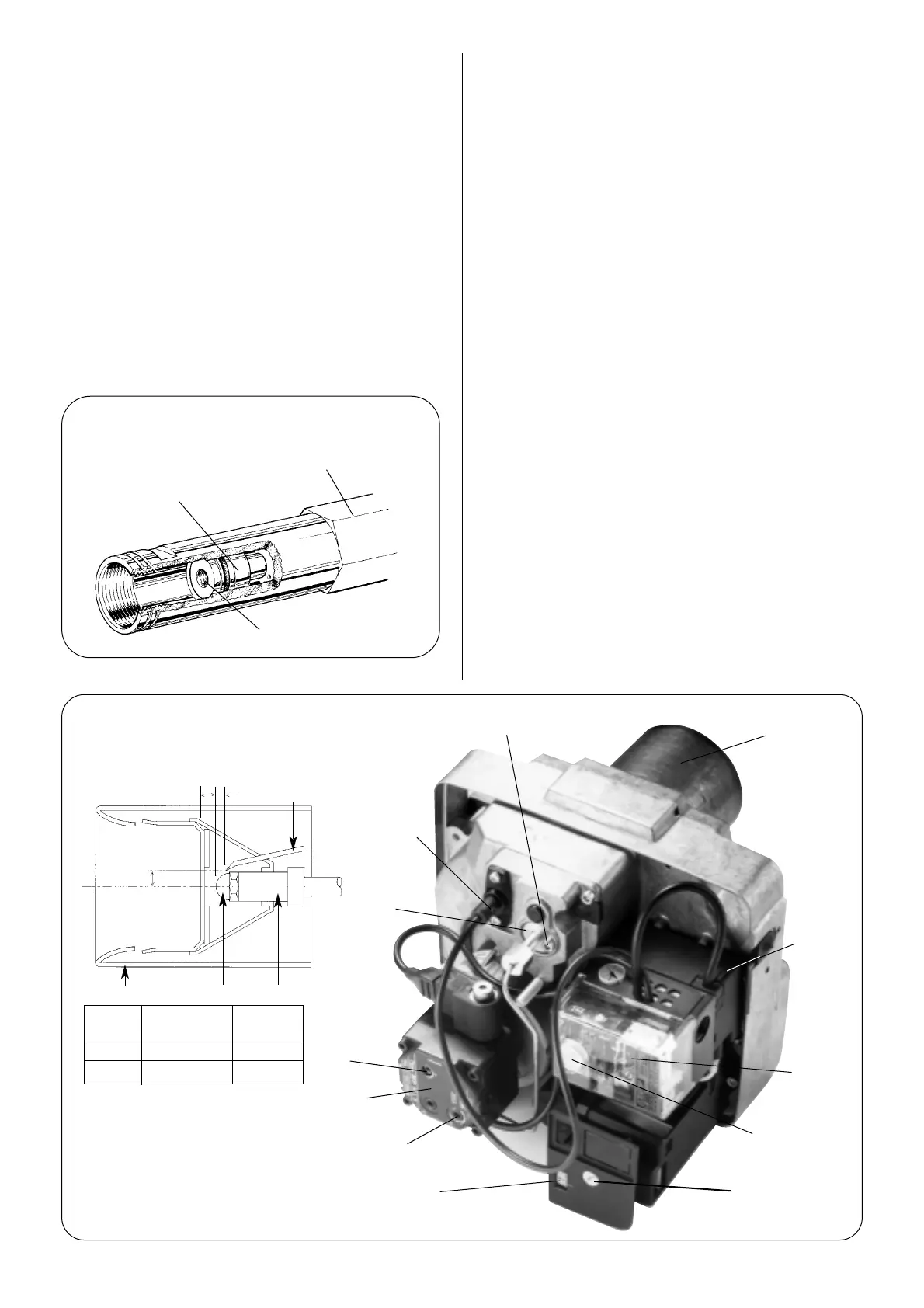

(b) Fasten an M5 screw, with a minimum length of 30mm, into the

threaded hole (A) and pull the screw to withdraw the check valve.

(c) Check that the nozzle holder is clear of any debris and clean if

necessary.

(d) Check that the three holes in the check valve are clear of any

debris. Discard the check valve if the holes cannot be cleared or

if the unit is defective and replace with a new one.

(e) Replace in the reverse order.

5. It is strongly recommended that the oil atomising nozzle is

replaced at each service. If this is not possible then remove and

clean the integral filter. Under no circumstances should the

nozzle be stripped into its component parts and never attempt

to clean the nozzle tip.

6. Check the electrodes and reset if necessary as shown in Figs.

23, 24, 25 and 26.

7. Replace the combustion head. Check that the nozzle lies

central to the combustion head and the head settings are as

shown in Figs. 23, 24, 25 and 26.

8. Withdraw the photocell from its housing and clean.

Check Valve

Nozzle Assembly

A

Fig. 22. Mechanical Shut-off Valve

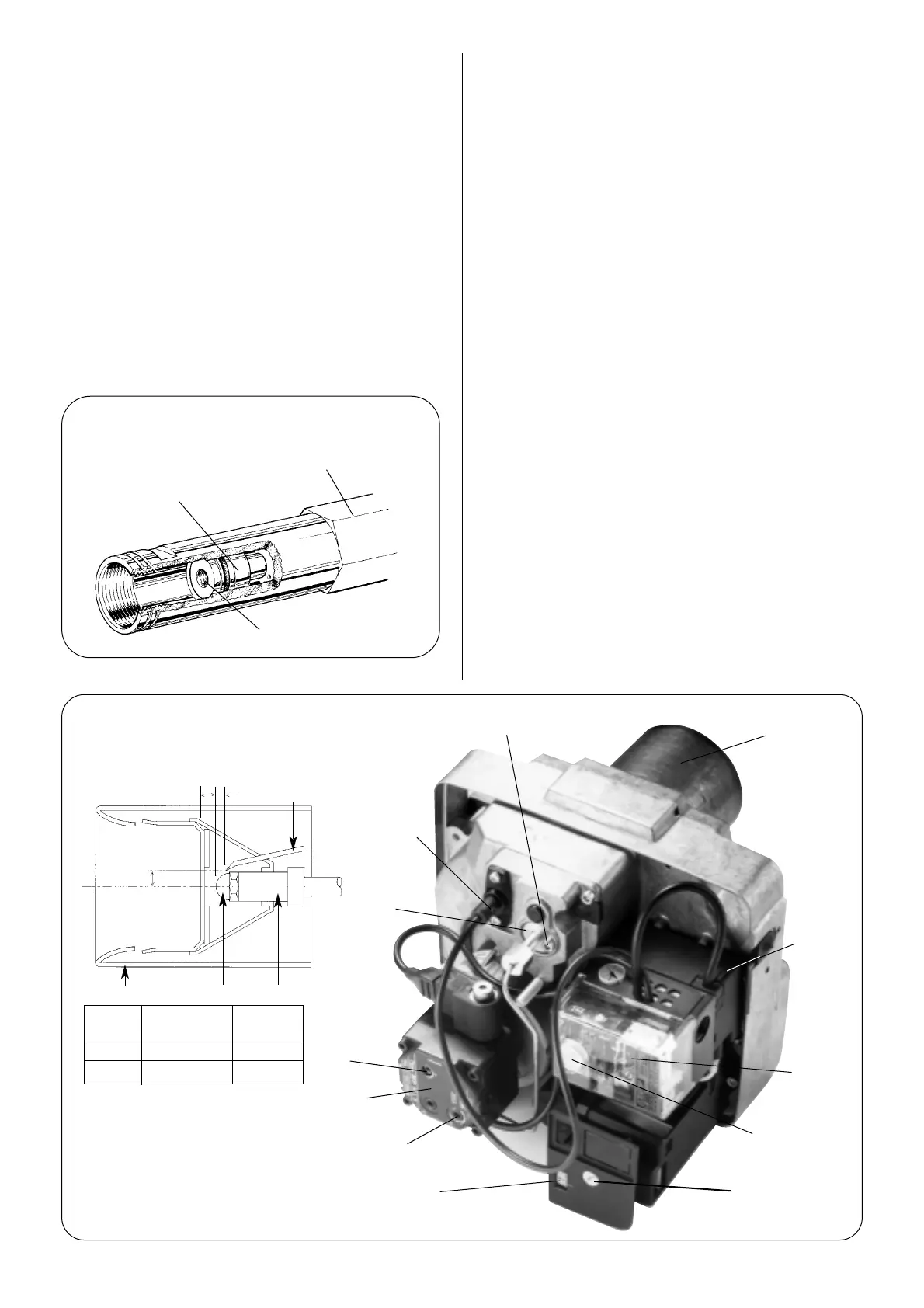

Combustion head

Locking screw

Transformer

Photocell

Control box

Lockout reset button

Air adjustment screwAir control indicator

(4mm hexagonal head)

Oil pump

Pressure

adjustment

screw

Pressure gauge

port

Adjusting

disc

Dimension

Output Head Type A

12

PL 6/7/21.5/10-E 3 mm

14 PL 6/7/21.5/10-E 5 mm

To adjust the nozzle position,

undo the locking screw located

at the rear of the nozzle line and

rotate the adjusting disc one

turn anti-clockwise to move

forward by 1 mm.

Fig. 23. Electro Oil Inter B9A Burner.

(12/14 model).

Combustion Head

Draught tube

Nozzle Nozzle block

Spark gap

2-2.5 mm

2 mm

10 mm

A

Loading...

Loading...