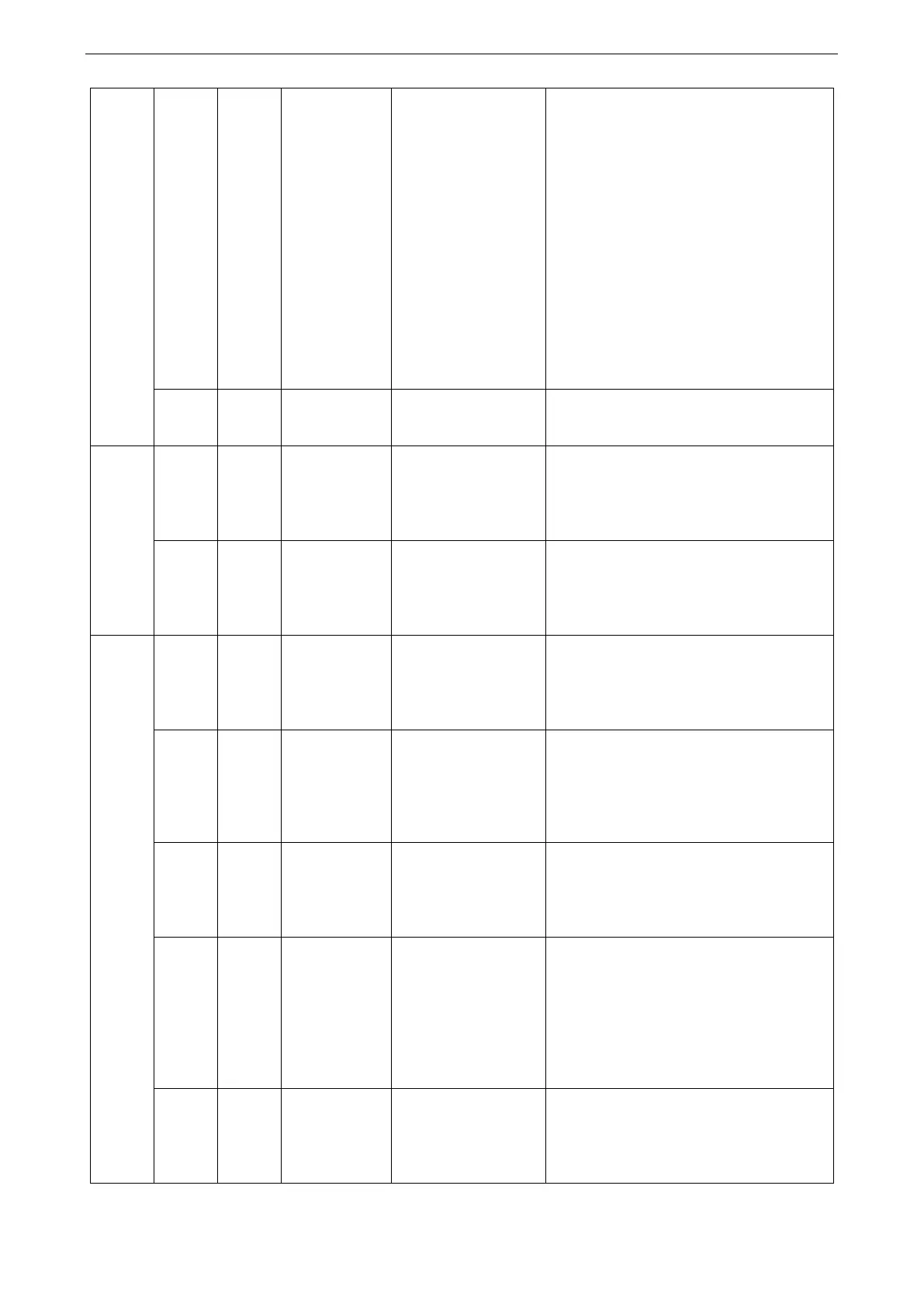

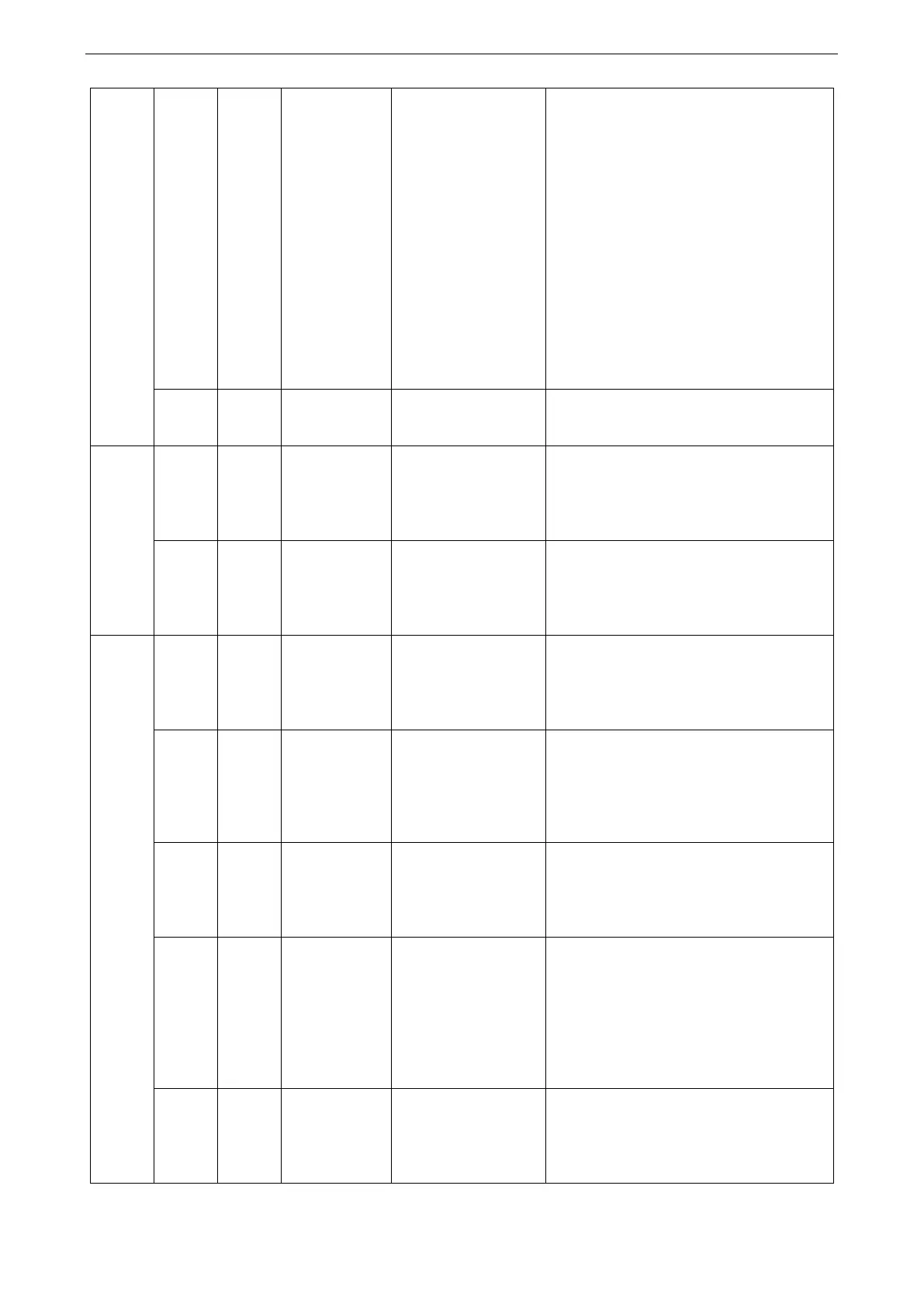

forces

(2) Load inertia is

large and the setting

of load inertia ratio

is wrong or the gain

is too small, which

leads to the

oscillation of

positioning.

mechanical installation;

(2) Increase the servo gain to improve

the anti-disturbance ability;

(3) Acquisition speed curve analysis;

When the first three peaks are

convergenced after pulse instruction

completed (0.8* | first peak | > | second

peak | and 0.8* | second peak | > | third

peak |), the driver should not alarm,

which can adjust the relevant threshold.

When the first three peaks speed are not

less than 300 rpm for three consecutive

times after the completion of the pulse

instruction, the driver will alarm.

(4) Contact manufacturers for technical

support

Excessive

motor

vibration

Check the motor installation

Failed to read

motor

parameters

Request to read

EEPROM failed

On the premise that the driver and motor

are matched and can be used together,

read the alarm shielding position of

motor parameters through P0-53, and set

the motor code correctly

Error writing

data to

encoder

EEPROM

Request to write

EEPROM failed

On the premise that the driver and motor

are matched and can be used together,

read the alarm shielding position of

motor parameters through P0-53, and set

the motor code correctly

Power

mismatch

between

driver and

motor

Such as 750W driver

with 200W motor

Match the correct motor and driver, and

use it after setting the motor code

correctly

When the

motor code is

read

automatically,

the motor

parameter is 0

On the premise that the driver and motor

are matched and can be used together,

read the alarm shielding position of

motor parameters through P0-53, and set

the motor code correctly

Reading

motor

parameter is

damaged

Parameter CRC

verification failed

On the premise that the driver and motor

are matched and can be used together,

read the alarm shielding position of

motor parameters through P0-53, and set

the motor code correctly

Encoder

software

version

mismatch

Encoder software

version mismatch

① Update driver firmware to maximize

current motor parameter performance

② Read the alarm shielding position of

motor parameters through p0-53, and set

the motor code correctly. At this time,

the motor parameters are in the driver,

which can work normally, but may affect

some performance

Motor code

does not

match

software

version

Encoder hardware

version is higher

than driver firmware

version

Contact the manufacturer's technical

support to update the driver firmware

Loading...

Loading...