23

not supported at the free end. Micrometer reading at each end of the

turned length (at A and B of Fig.4) should be the same.

To correct a difference in readings, slacken and release the

four-headstock hold-down screws (J) shown in Fig.4 and adjust the

set-over screw (K) beneath the headstock. Then tighten all screws, after

adjustment and repeat the test-cut/micrometer-reading sequence until

micrometer readings are identical, so machine now cutting

absolutely parallel.

The Importance and Methods of Spindle Leveling Adjustment

1. Switch on to make the Spindle turn while the

Spindle is set up at 1170r.p.m. By putting the palm of

the left hand on the Headstock cover to fell its chatter.

An unrevealing Spindle will lead to lathe chatter.

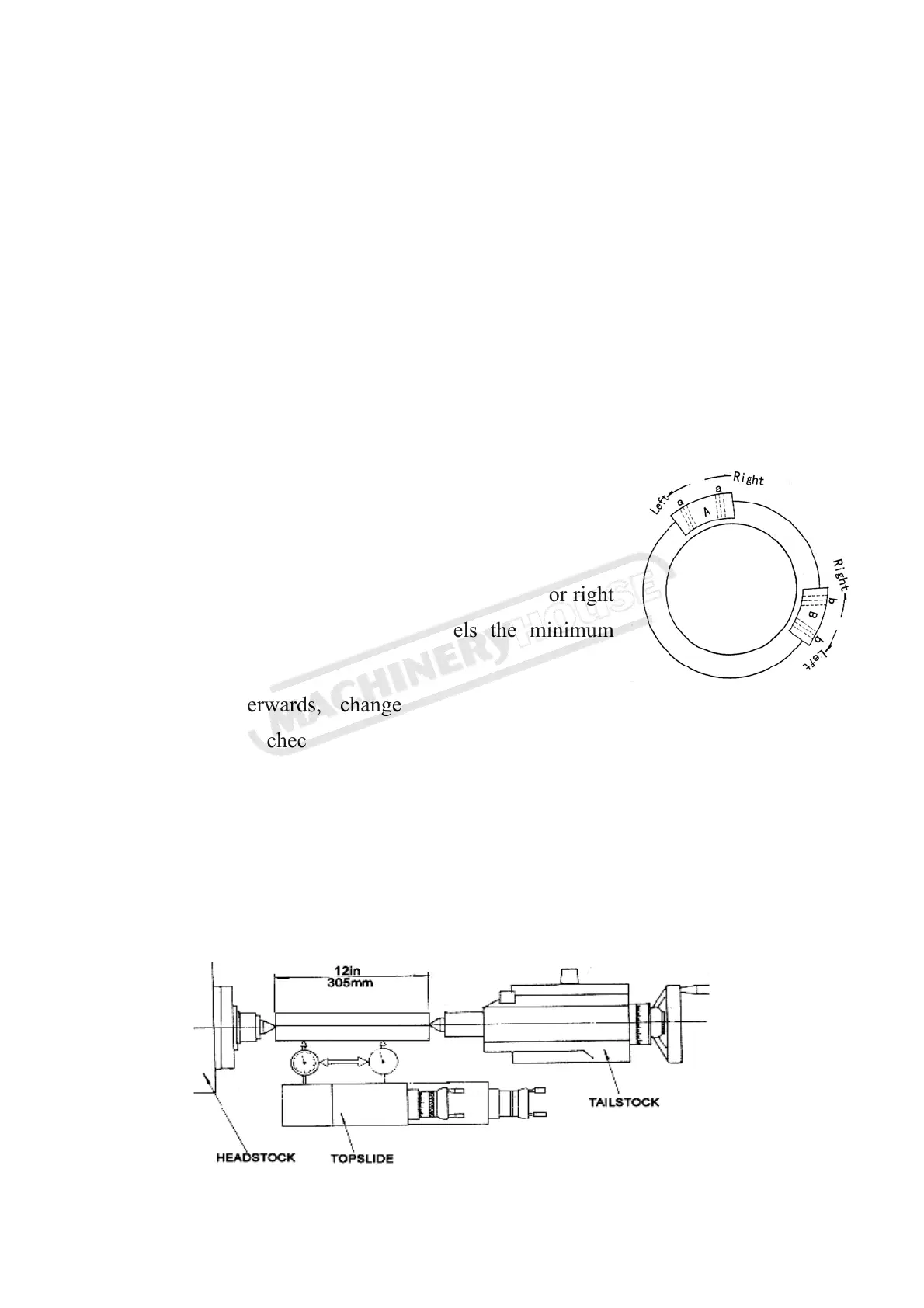

Move Leveling Block (either “A” or “B”) left or right

to adjust until your left hand feels the minimum

chatter.

2. Afterwards, change the Spindle speed to 1800r.p.m. or

770r.p.m.and check the Leveling with the same way as we did at

770r.p.m.by adjusting the Leveling Block “A” or “B”.

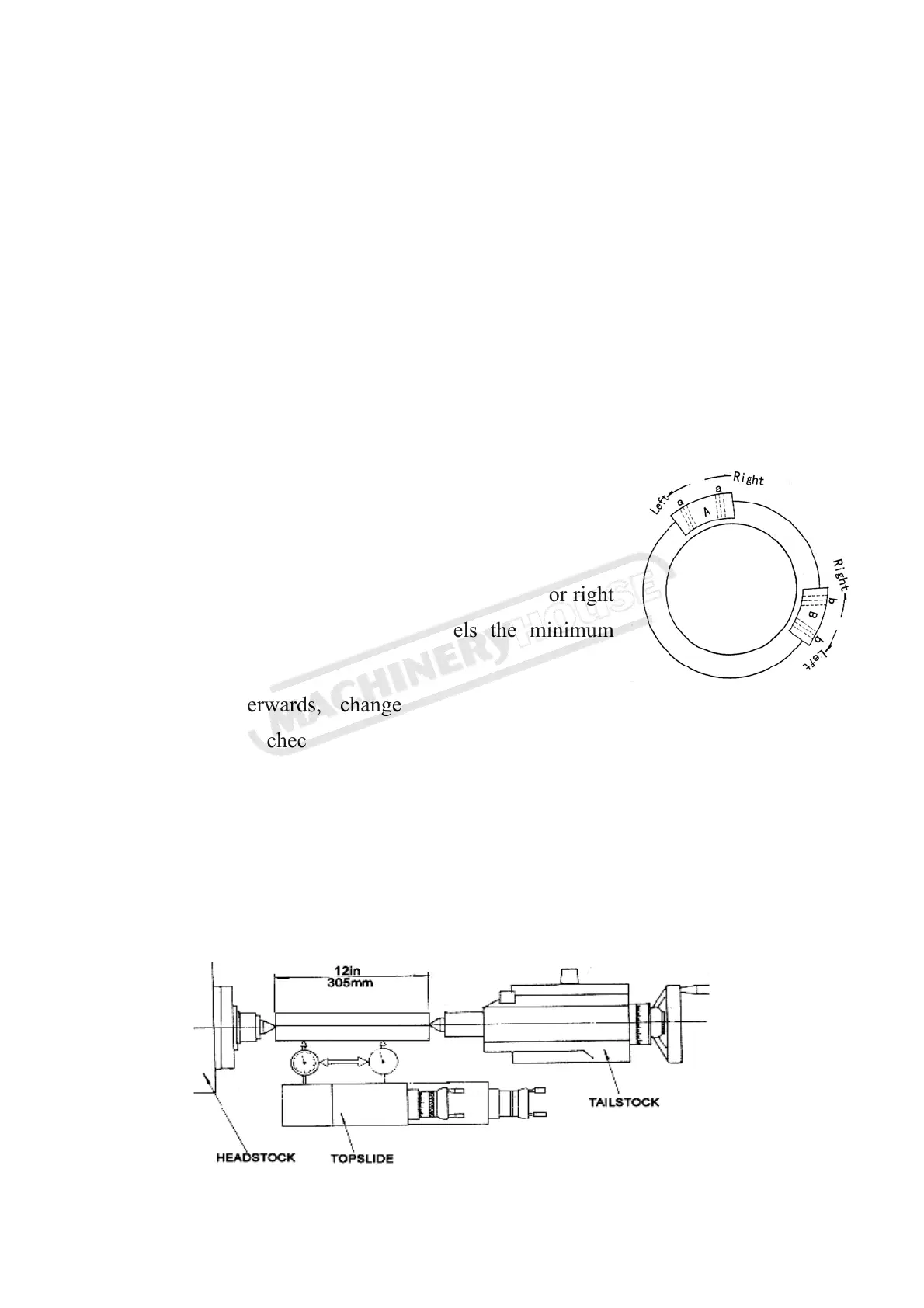

8. Lathe Alignment Part.2

Using a 12in. (305mm.) ground steel bar fitted between headstock

and tailstock centers, check the alignment by fitting a dial-test indicator to

the topside and traversing the center line of the bar. (Fig.6).

Fig.5

Fig.6

Instructions Manual for CL-38 (L190)

Loading...

Loading...