28

B. Metric threads

Same as above when a Metric Screw is installed.

To provide for the various pitches of metric threads, several gears

having different numbers of teeth are mounted on the lower end of the

shaft. The

vertical position of the thread dial indicator is changed as required so

that the correct gear for the pitch of the thread to be cut wills mesh with

the leadscrew.

Each graduation on the dial is marked with a letter, which indicates

the points at which the half nuts may be engaged for certain threads. A

diagram is supplied with the thread dial to show which gear and

graduations must be used for each pitch of metric screw thread.

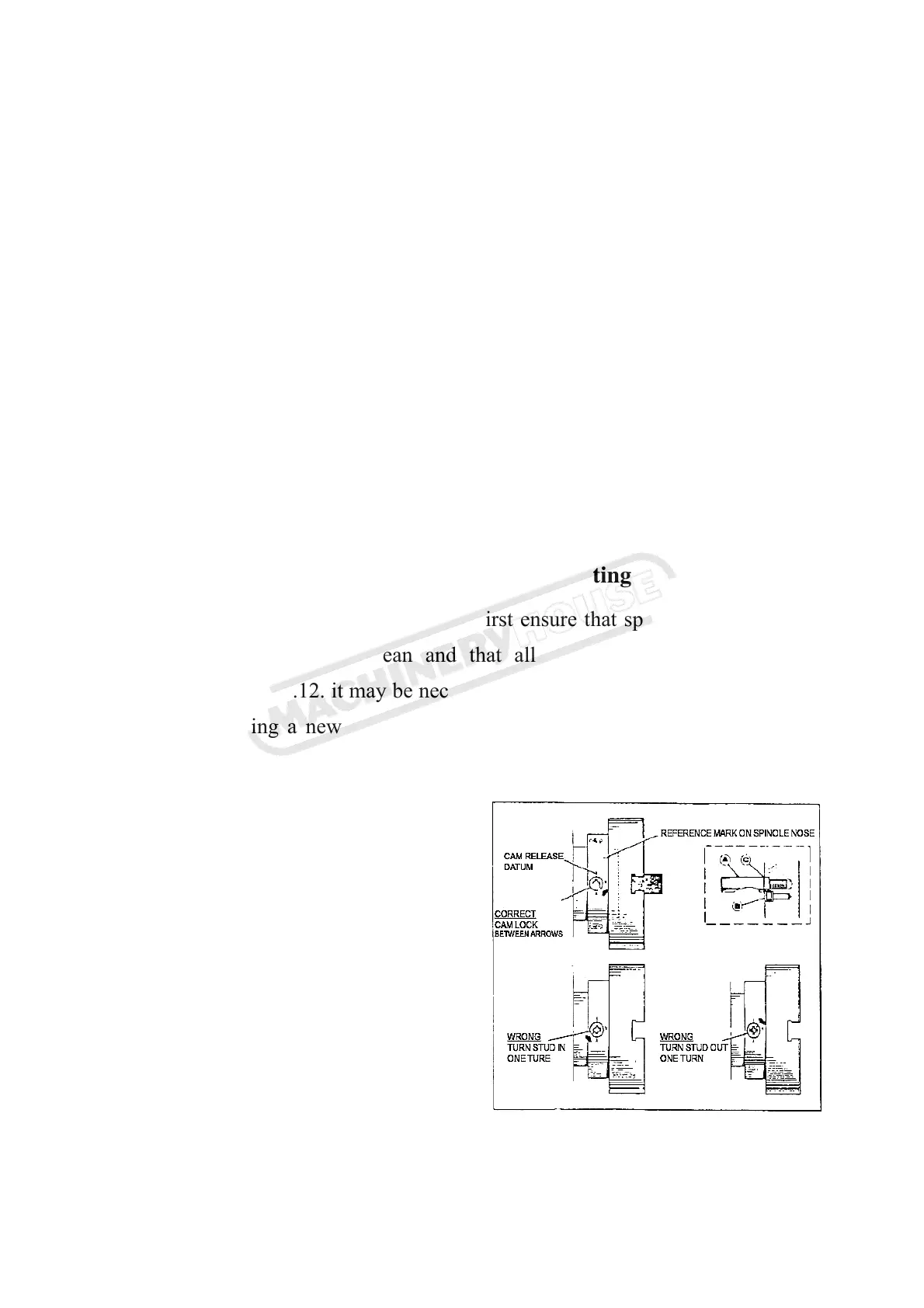

14. Chucks and Chucks Mounting

When fitting chucks or faceplates, first ensure that spindle and chuck

tapers are scrupulously clean and that all cams lock in the correct

positions; see Fig.12. it may be necessary to re-set the cam lock studs (A)

when mounting a new chuck. To do this, remove the cap-head locking

screws (B) and set each stud so that the scribed ring (C) is flush with the

rear face of the chuck-with the slot

lining up with the locking screw hole.

See Fig.13.

Now, mount the chuck or

faceplate on the spindle nose and

tighten the three cams in turn.

When fully tightened, the cam

lock line on each cam should be

between the two V marks on the

spindle nose. If any of the cams

do not tighten fully within these limit marks, remove the chuck or

Fig.13

Instructions Manual for CL-38 (L190)

Loading...

Loading...